A fish meal crushing device

A crushing device and fishmeal technology, applied in grain processing, etc., can solve problems such as low efficiency and high processing costs, and achieve the effects of improving work efficiency, saving investment, and reducing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

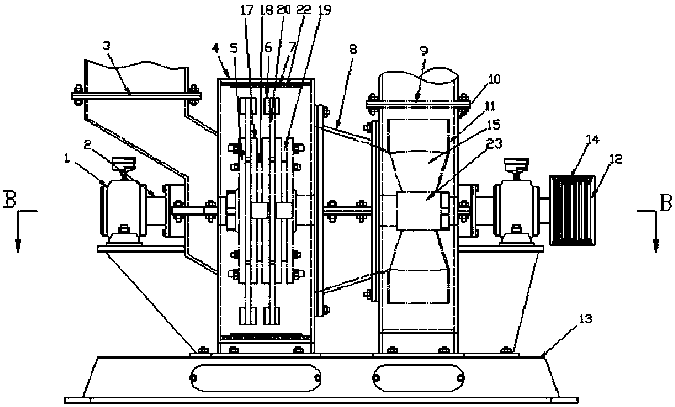

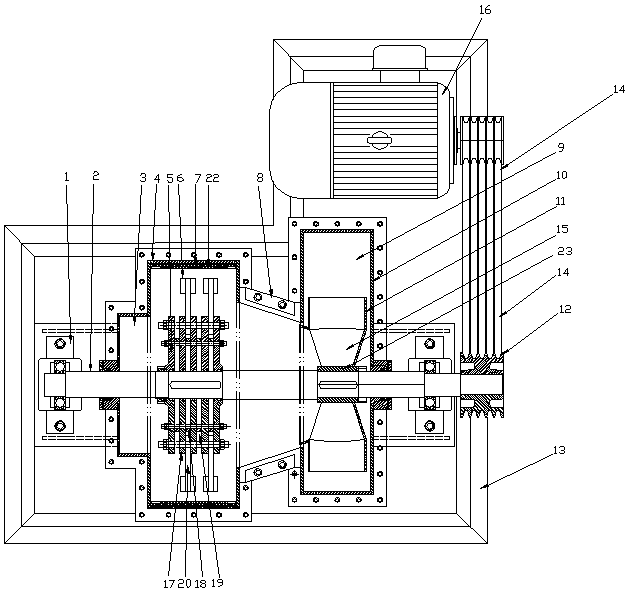

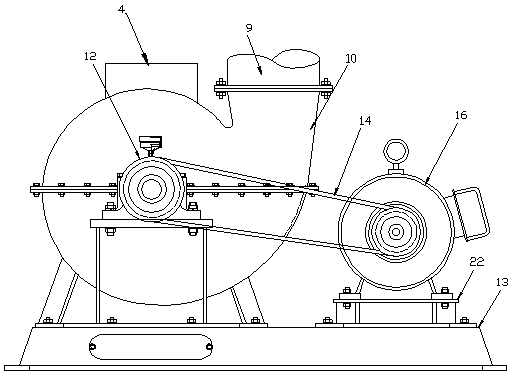

[0017] As shown in above-mentioned accompanying drawing, the present invention is made up of pulverizer part, wind feeder part, both connecting part and motor. The specific structure is like this, such as figure 1 , figure 2 As shown, on the machine base 13, the pulverizer housing 4, the wind feeder housing 10 and the motor 16 are installed and fixed. , the device on the inner peripheral wall of the cylinder is struck by the plate 7, such as Figure 6 , Figure 7 and Figure 8 As shown, the side of the struck plate 7 facing the main shaft 2 is provided with convex ribs 22 of equal height and equal spacing, and the distance between every two adjacent convex ribs 22 is 25-30 mm. Evenly divide 6 and be fixed on the inner surface of pulverizer housing 4 with bolt, can disassemble and replace at any time. Such as figure 1 , figure 2 and image 3 As shown, bearing housings 1 are also installed on both ends of the machine base 13, and a main shaft 2 is installed through bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com