Sintering waste heat power generation system based on buffering power circuit

A waste heat power generation and power circuit technology, which is applied in waste heat treatment, combined combustion mitigation, machine/engine, etc., can solve the problems of waste heat power generation unstable operation, low utilization rate of thermal display, high operating cost, etc., to reduce equipment investment, Reduce equipment investment and operating costs, and reduce operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

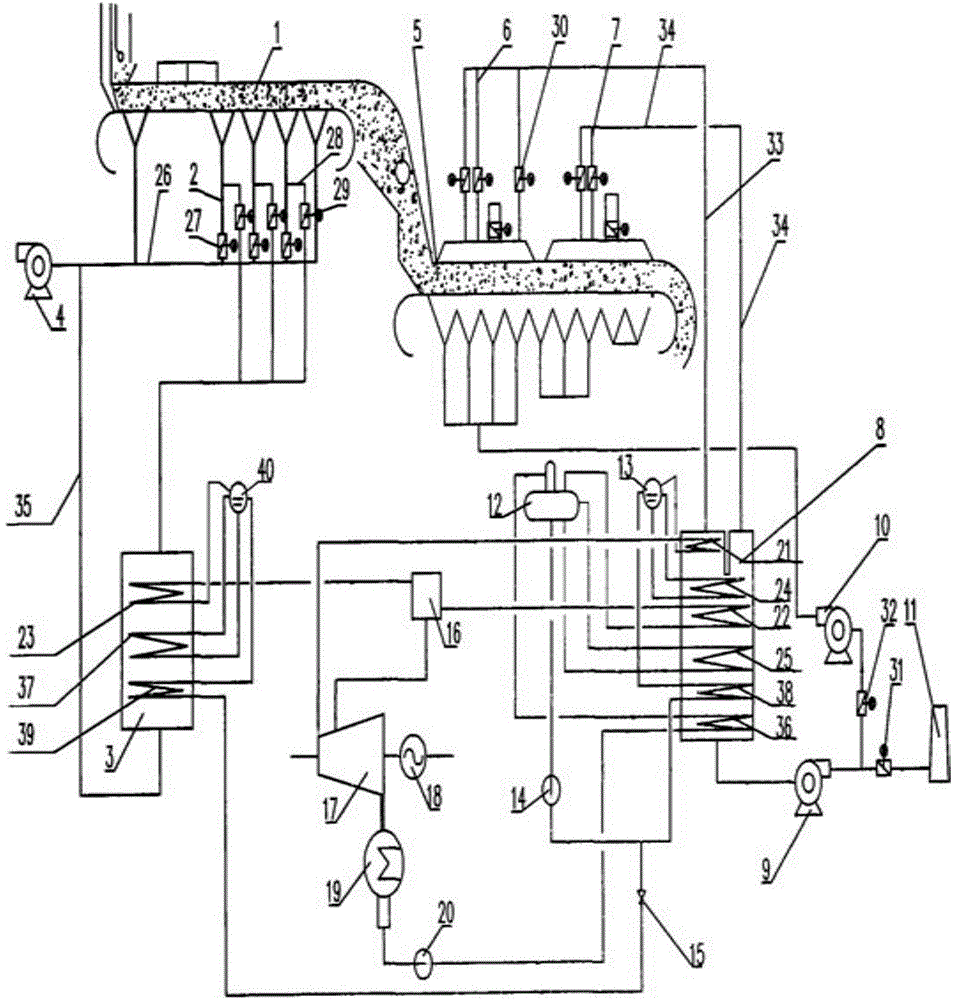

[0025] Such as figure 1As shown, the present invention includes a sintering machine hot flue gas system, a hot waste gas waste heat utilization system and a sintering waste heat power generation thermal system;

[0026] The hot flue gas system of the sintering machine is as follows: a hot flue gas outlet pipe 2 is provided in each of the bellows at the bottom of the sintering machine 1, and the other end of the hot flue gas outlet pipe 2 communicates with the hot flue gas manifold 26 at the tail. Each hot flue gas outlet pipe 2 is provided with a hot flue gas outlet pipe valve 27 at one end close to the hot flue gas manifold 26 at the tail, and a main exhaust fan 4 is arranged at one end of the hot flue gas manifold 26 at the tail, counting down from the tail of the sintering machine Starting from the second hot flue gas outlet pipe 2, hot flue gas branch pipes 28 and hot flue gas branch pipe valves 29 are arranged on 2 to 4 hot flue gas outlet pipes 2. The other end of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com