Intermediate-strength aluminium alloy rod and preparation method thereof

A medium-strength aluminum alloy and alloy liquid technology, which is applied in the field of aluminum alloys, can solve the problems that medium-strength aluminum alloys cannot obtain properties, and achieve the effects of good mechanical properties and corrosion resistance, prevention of strength loss, and reasonable deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

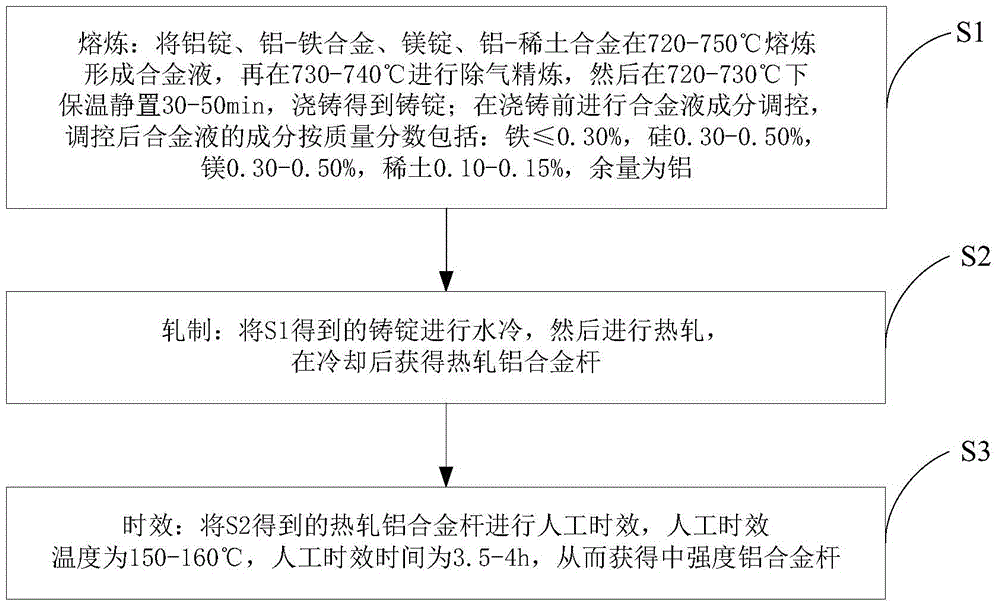

[0029] refer to figure 1 , the present invention proposes a method for preparing a medium-strength aluminum alloy rod, comprising the following steps:

[0030] S1: Smelting: Melt aluminum ingots, aluminum-silicon alloys, aluminum-iron alloys, magnesium ingots, and aluminum-rare earth alloys at 720-750°C to form alloy liquids, then conduct degassing and refining at 730-740°C, and then refine them at 720-730°C Keep it warm at ℃ for 30-50 minutes, and cast ingots to obtain ingots; before casting, adjust the composition of the alloy liquid. After the adjustment, the composition of the alloy liquid includes: iron ≤ 0.30%, silicon 0.30-0.50%, magnesium 0.30-0.50% , rare earth 0.10-0.15%, the balance is aluminum;

[0031] S2: Rolling: water-cooling the ingot obtained in S1, and then hot-rolling to obtain a hot-rolled aluminum alloy rod after cooling;

[0032] S3: Aging: artificially aging the hot-rolled aluminum alloy rod obtained in S2, the artificial aging temperature is 150-160°...

Embodiment 1

[0035] A method for preparing a medium-strength aluminum alloy rod proposed in this embodiment includes the following steps:

[0036] S1: Melting: Put the aluminum ingot into the melting furnace. After the aluminum ingot is melted into a liquid state at 740°C, add aluminum-silicon alloy, aluminum-iron alloy, aluminum-rare earth alloy, and wait for the aluminum-silicon alloy, aluminum-iron alloy, aluminum - After the rare earth alloy is melted, magnesium ingots are added to form an alloy liquid, and a refining agent is added at 735°C for degassing and refining, and the heat preservation is carried out at 725°C for 40 minutes, and the ingot is obtained by casting;

[0037] Among them, the composition of the alloy liquid is adjusted before casting, and the composition of the alloy liquid after adjustment includes: 0.20% iron, 0.40% silicon, 0.40% magnesium, 0.12% rare earth, and the balance is aluminum;

[0038] During the degassing and refining process, the amount of refining ag...

Embodiment 2

[0042] A method for preparing a medium-strength aluminum alloy rod proposed in this embodiment includes the following steps:

[0043] S1: Melting: Put the aluminum ingot into the melting furnace. After the aluminum ingot is melted into a liquid state at 750°C, add aluminum-silicon alloy, aluminum-iron alloy, aluminum-rare earth alloy, and wait for the aluminum-silicon alloy, aluminum-iron alloy, aluminum - After the rare earth alloy is melted, magnesium ingots are added to form an alloy liquid, and a refining agent is added at 740°C for degassing and refining, and the heat preservation is carried out at 730°C for 30 minutes, and cast to obtain ingots;

[0044] Among them, the composition of the alloy liquid is controlled before casting. After the control, the composition of the alloy liquid includes: 0.23% iron, 0.30% silicon, 0.50% magnesium, 0.10% rare earth, and the balance is aluminum;

[0045] During the degassing refining process, the amount of refining agent added is 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com