Greasy dirt cleansing agent and preparation method thereof

A technology of oil cleaning agent and diglycidyl ether, applied in detergent compositions, chemical instruments and methods, non-surface-active cleaning solvents, etc., can solve problems affecting the service life of machine parts, corrosion of parts and hardware, damage to the earth environment and other problems, to achieve the effect of good cleaning effect, good cleaning strength and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

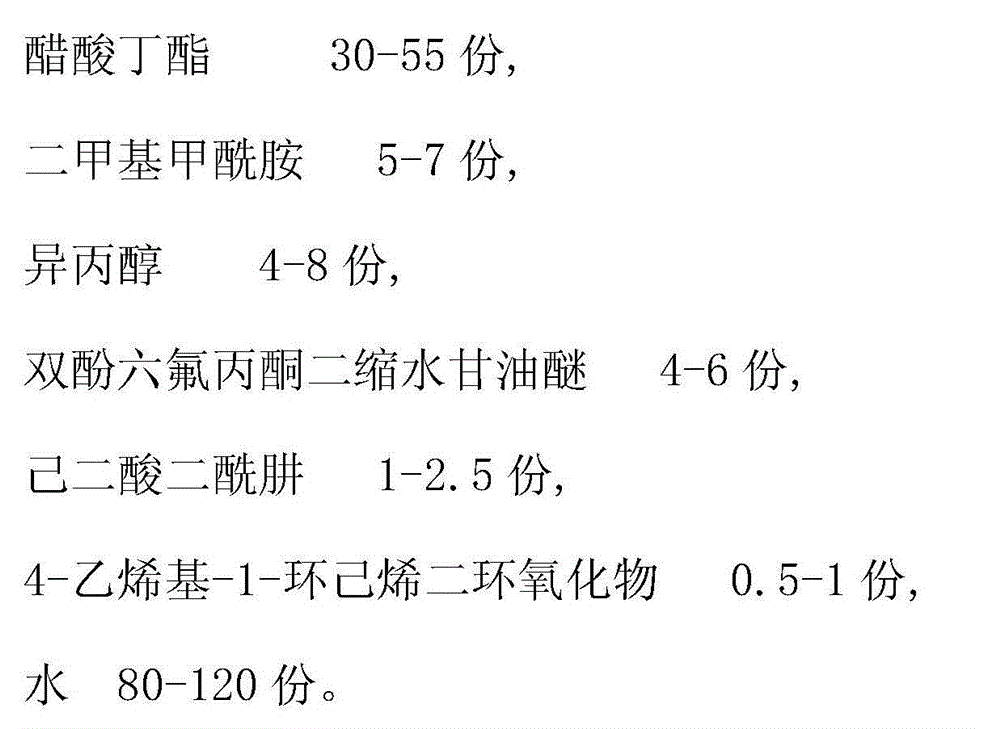

[0023] (1) Add 30kg of butyl acetate, 5kg of dimethylformamide and 4kg of isopropanol into 80kg of water, and stir evenly;

[0024] (2) Add 4kg of bisphenol hexafluoroacetone diglycidyl ether, 1kg of adipic acid dihydrazide, 0.5kg of 4-vinyl-1-cyclohexene diepoxide at 35°C, and use 400 rpm Mix at agitation speed for 15 minutes;

[0025] (3) Sonicate at 40° C. for 10 minutes to obtain an oil stain cleaning agent.

[0026] The performance test results of the prepared oil stain cleaning agent are shown in Table 1.

Embodiment 2

[0028] (1) Add 30kg of butyl acetate, 7kg of dimethylformamide and 8kg of isopropanol into 80kg of water, and stir evenly;

[0029] (2) Add 4kg of bisphenol hexafluoroacetone diglycidyl ether, 1kg of adipic acid dihydrazide, 0.5kg of 4-vinyl-1-cyclohexene diepoxide at 35°C, and use 400 rpm Mix at agitation speed for 15 minutes;

[0030] (3) Sonicate at 40° C. for 10 minutes to obtain an oil stain cleaning agent.

Embodiment 3

[0032] (1) Add 55kg of butyl acetate, 7kg of dimethylformamide and 8kg of isopropanol into 120kg of water, and stir evenly;

[0033] (2) Add 6kg of bisphenol hexafluoroacetone diglycidyl ether, 1kg of adipic acid dihydrazide, 0.5kg of 4-vinyl-1-cyclohexene diepoxide and dodecyl dimethyl at 50°C Betaine 1.5kg, mixes 20 minutes with the stirring rate of 450 rev / mins;

[0034] (3) Add 1 kg of paraffin oil, and ultrasonicate at 30° C. for 20 minutes to obtain an oil stain cleaning agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com