Mechanical cleaning equipment and cleaning method for cleaning water circulation system and storage tank

A circulation system and mechanical cleaning technology, applied in the direction of cleaning method using liquid, cleaning method using gas flow, cleaning method and utensils, etc., can solve problems such as low efficiency and complicated operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

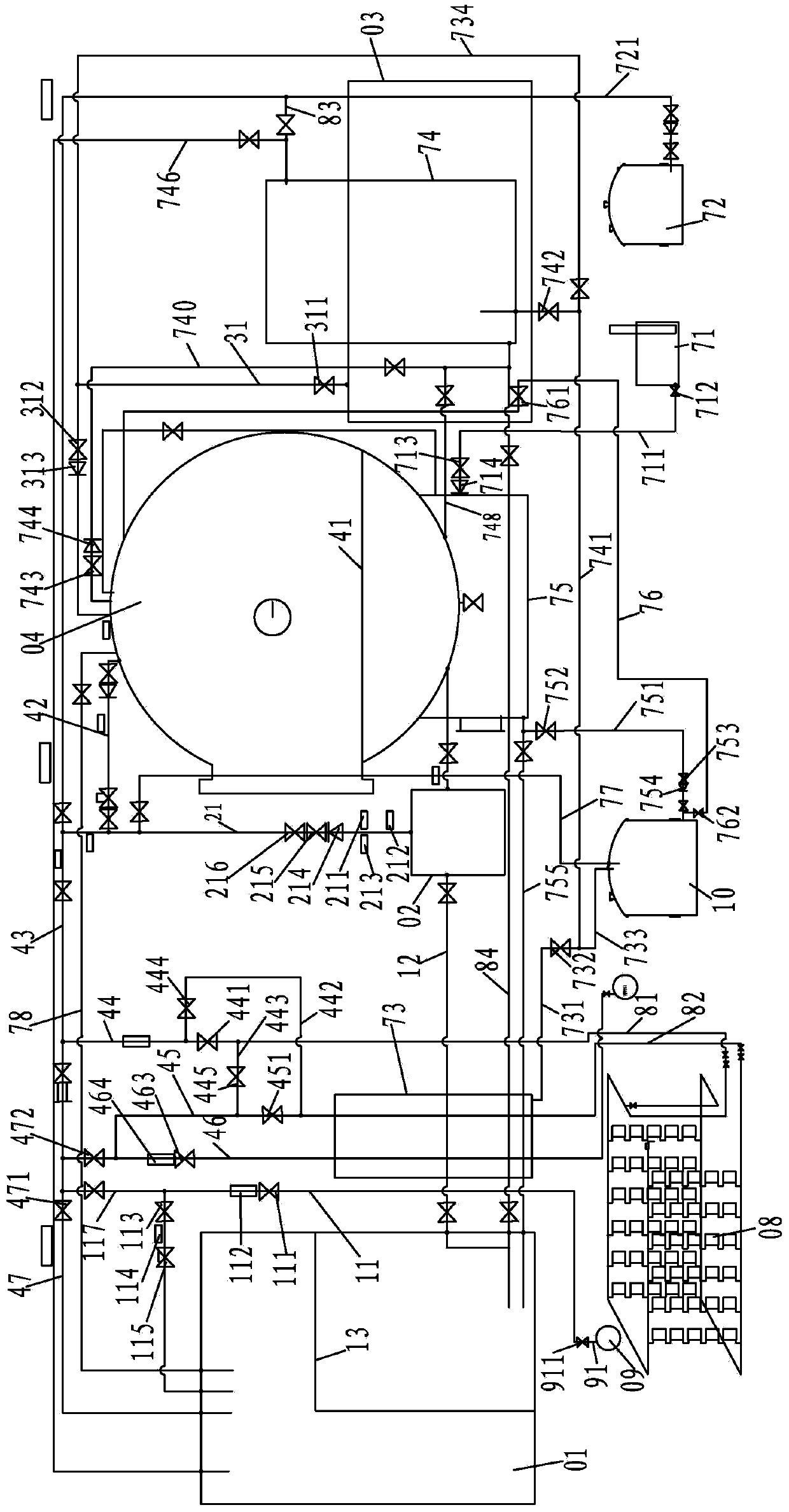

[0019] Such as figure 1 As shown, the mechanical cleaning equipment used for cleaning the water circulation system and the storage tank of the present invention includes a water supply system and an air supply system. The water supply system includes an impurity separation box 01 and an explosion-proof centrifugal pump 02. The impurity separation box 01 is provided with a separation box filter plate 13. The impurity separation box 01 is connected to the water source through the water inlet pipeline 11. The connection between the water inlet pipeline 11 and the impurity separation box 01 is located above the filter plate 13 of the separation box. The water inlet pipeline 11 is provided with a first on-off valve 111 and a mirror 112 , the second switch valve 113, the water inlet pressure gauge 114, the metering water meter 115, the impurity separation box 01 is connected to the inlet of the explosion-proof centrifugal pump 02 through the water supply pipeline 12, and the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com