Fan anti-sticking oil and oily dirt cleaning device, range hood and method of cleaning range hood

A technology of cleaning device and range hood, which is applied in the direction of removing oil fume, heating method, household heating, etc., can solve the problems of low cleaning efficiency of oil scale and unsatisfactory anti-oil pollution effect, so as to ensure cleanliness, ensure anti-sticking oil, and reduce pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

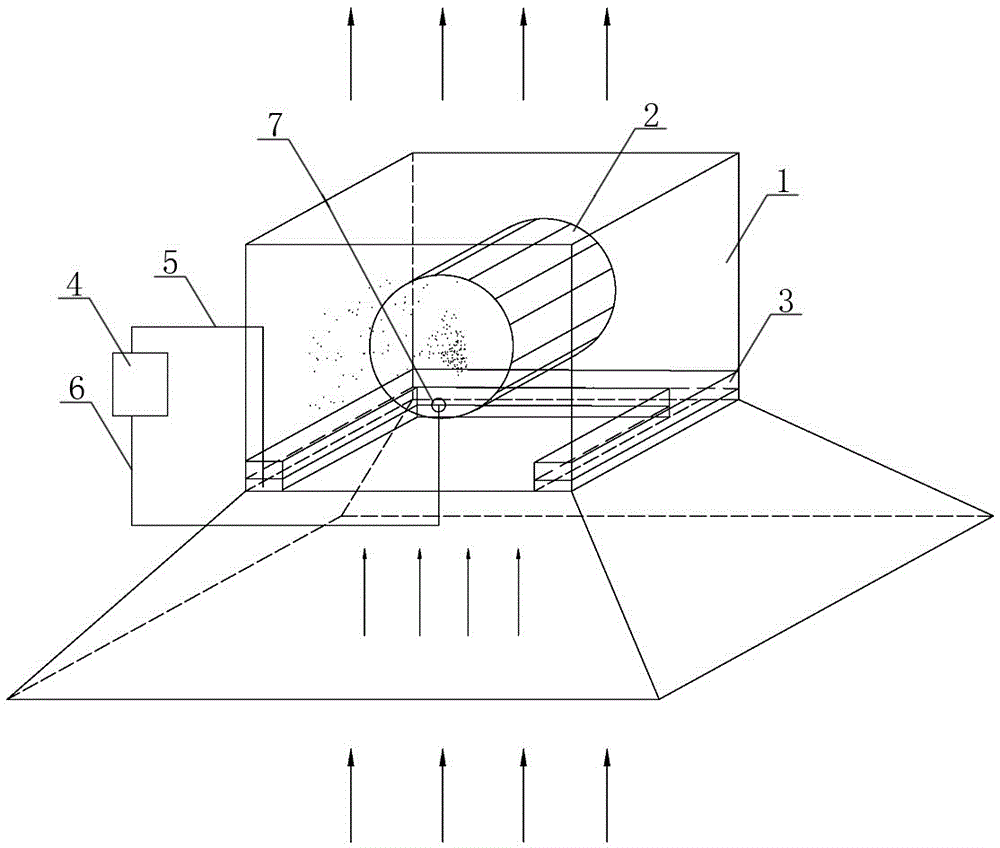

[0040] Embodiment one sees figure 1As shown, the device is applied in a centrifugal range hood 1, which includes a housing 10 and an impeller 2 located inside the housing, and also includes a water mist device that forms a water film layer on the inner wall of the housing and the outer surface of the impeller 2 , the water mist device is arranged on one side of the air inlet of the impeller 2; the inner wall of the housing 10 is provided with a water tank 3 that collects the circulating water of the water film layer on the inner wall; the water mist device and the water tank 3 are sequentially connected with Outlet pipe 6, water pump 4 and water suction pipe 5.

[0041] Using the water pump 4 to supply water to the water mist device can control the water intake very conveniently, so that the water mist device can continuously and stably spray water mist particles. In order to reduce the diameter of water mist particles and provide uniform distribution of water mist particles,...

Embodiment 2

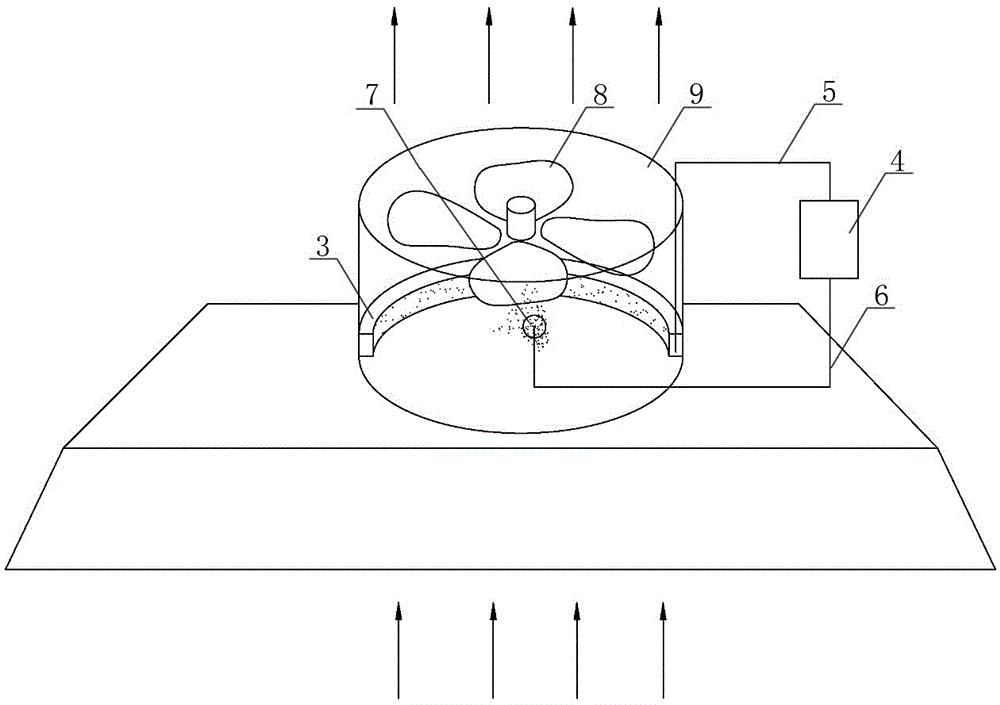

[0048] Embodiment two see figure 2 As shown, the difference from the first embodiment is that the device is connected to the axial flow range hood 9, including the housing 10 and the fan blade 8 inside the housing, and also includes the inner wall of the housing and the fan blade 8 A water mist device forming a water film layer on the surface, the water mist device is arranged on one side of the air inlet of the fan blade 8; the inner wall of the housing 10 is provided with a water tank 3 for collecting circulating water of the water film layer on the inner wall; A water outlet pipe 6 , a water pump 4 and a water suction pipe 5 are sequentially connected between the water mist device and the water tank 3 .

[0049] The water tank 3 is detachably connected to the housing 10; the water tank 3 is a circular ring, and a circle is arranged along the lower inner wall of the housing 10; or the water tank 3 is a strip structure, and is arranged along one side of the inner wall of the...

Embodiment 3

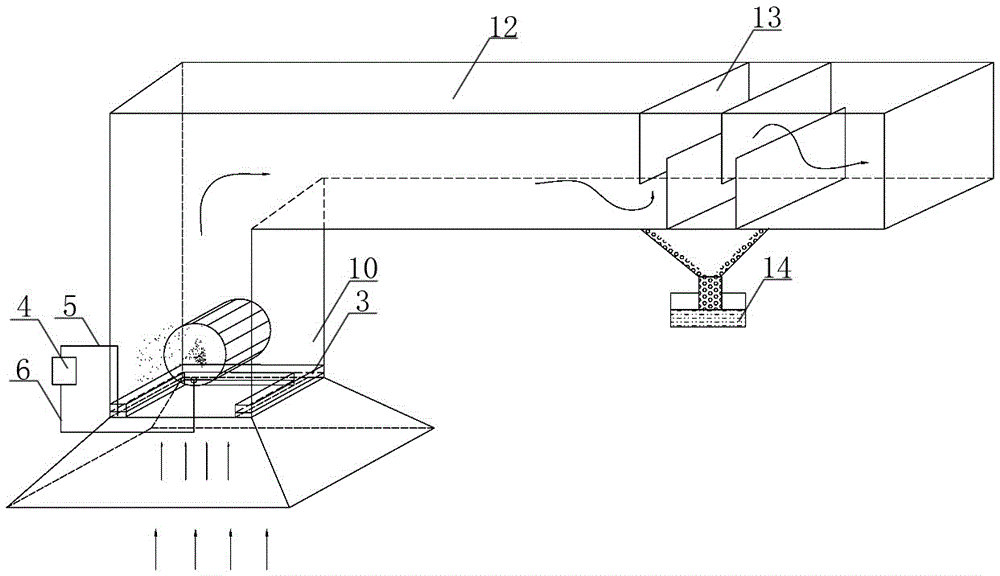

[0052] Embodiment three see image 3 As shown, different from Embodiment 1, a purifier is also provided in the exhaust duct 12 of the range hood; the purifier is suitable for reducing the emission of oil fume when the amount of oil fume discharged by the centrifugal range hood is large. , and the purifier can purify oil fume, which is beneficial to protect the environment. The purifier includes a group of demister plates 13 for blocking the water-oil mixture and a collection tank 14 located below the demister plates 13; the demister plates 13 are distributed alternately, and the demister plates 13 are used for blocking the water-oil mixture, The water mist and oil fume flowing through the impeller 2 form a water mist-oil fume mixture, and the larger particles in the water mist-oil fume mixture sink due to one or more inertias with the defogging plate 13 to form a water-oil mixed liquid flow. Finally, it is collected by the collection tank 14 located under the multiple defoggi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com