Method for treating calcium in high-calcium fly ash

A high-calcium fly ash and treatment method technology, applied in the direction of calcium/strontium/barium halide, calcium/strontium/barium chloride, calcium/strontium/barium nitrate, etc., can solve the problem of rising acid and alkali consumption, high Problems such as the limitation of comprehensive utilization of calcium fly ash and the increase of secondary residues have achieved the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

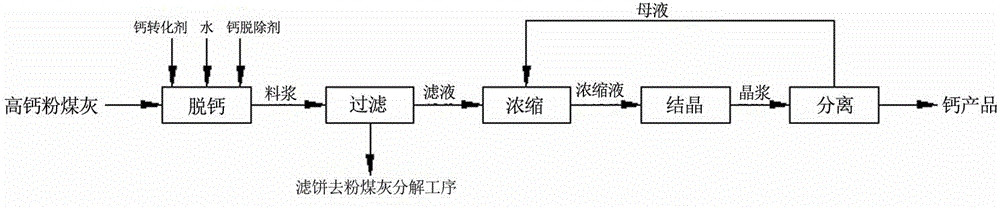

Image

Examples

Embodiment 1

[0049] Source and composition of fly ash: Henan Tongbai fly ash, CaO 28.38%; Al 2 o 313.19%; SiO 2 44.22%; SO 4 2- 4.48%; MgO 1.68%; Fe 2 o 3 4.26%.

[0050] Weigh 1000g of fly ash into a beaker, add 3000ml of water and stir to form a slurry, then add 185g of ammonium bicarbonate, stir and react for 2 hours at room temperature, filter, add appropriate amount of water to wash. Reaction received 1800g filter cake, containing SO 4 2- 3.80g, the conversion rate of calcium sulfate is 91.52%.

[0051] Add 1800g of filter cake to 500ml of water and stir to form a slurry, add 666ml of 65% nitric acid at room temperature, keep the reaction at 65°C for 1h, filter and wash, and obtain 1800ml of calcium nitrate solution, containing Ca(NO 3 ) 2 788g, 900g filter cake after decalcification, containing 1.63% CaO, 14.67g combined CaO, calcium removal rate 94.83%.

[0052] Heat and evaporate 1800ml of calcium nitrate solution with 32Be' to 55 Be', cool and add 30g of calcium nit...

Embodiment 2

[0056] Source and composition of fly ash: fly ash from Henan Xinxiang Xinlianxin Fertilizer Co., Ltd., CaO 33.53%; Al 2 o 3 17.05%; SiO 2 32.89%; SO 4 2- 8.53%; MgO 2.00%; Fe 2 o 3 3.29%.

[0057] Weigh 100kg of fly ash into a beaker, add 200L of water and stir to form a slurry, then add 9.81kg of sodium carbonate, stir and react at 80°C for 2h, then filter, add appropriate amount of water to wash. Reaction received 170kg filter cake, containing SO 4 2- 0.85kg, the conversion rate of calcium sulfate is 90.04%.

[0058] Add 170kg of filter cake to 80L of water and stir to form a slurry, add 96L of 36% hydrochloric acid at room temperature, keep it at 95°C for 1 hour, filter and wash to obtain 247L of calcium chloride solution, containing CaCl 2 62kg, 85kg filter cake after decalcification, containing 2.65% CaO, 2.25kg combined CaO, 93.29% calcium removal rate

[0059] Calcium chloride solution 247L, containing CaCl 2 62kg, the calcium chloride concentration is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com