High heat dissipation resin grinding wheel

A resin grinding wheel, high heat dissipation technology, applied in the field of grinding, can solve the problems of high grinding temperature, low grinding efficiency, poor self-sharpening, etc., achieve high grinding efficiency, material saving, and good shape retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

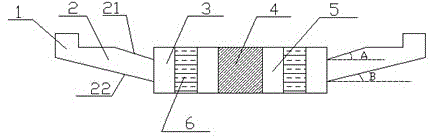

[0013] Such as figure 1 As shown, the present invention is realized by adopting the following technical solutions: a high heat dissipation resin grinding wheel, including a through hole 4 and a grinding layer 1, and between the through hole 4 at the central position and the grinding layer 1 at the outermost end, there are The fixed disc 5, the heat dissipation layer 6 and the annular resin support disc 2, the grinding layer 1 is sleeved on the outer ring surface of the annular resin support disc 2, and the glass fiber is adhered between the heat dissipation layer 6 and the annular resin support disc 2 Enhanced mesh 3.

[0014] As a preferred solution, a plurality of arc-shaped fan blades are arranged on the heat dissipation layer 6 of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com