Magnetic graphene-based platinum-nickel bimetallic catalyst and preparation method of magnetic graphene-based platinum-nickel bimetallic catalyst

A bimetallic catalyst, alkenyl platinum technology, applied in the field of catalysts, can solve problems such as difficulty in recovering nano-catalysts, and achieve the effects of simple and efficient recovery process, low cost, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

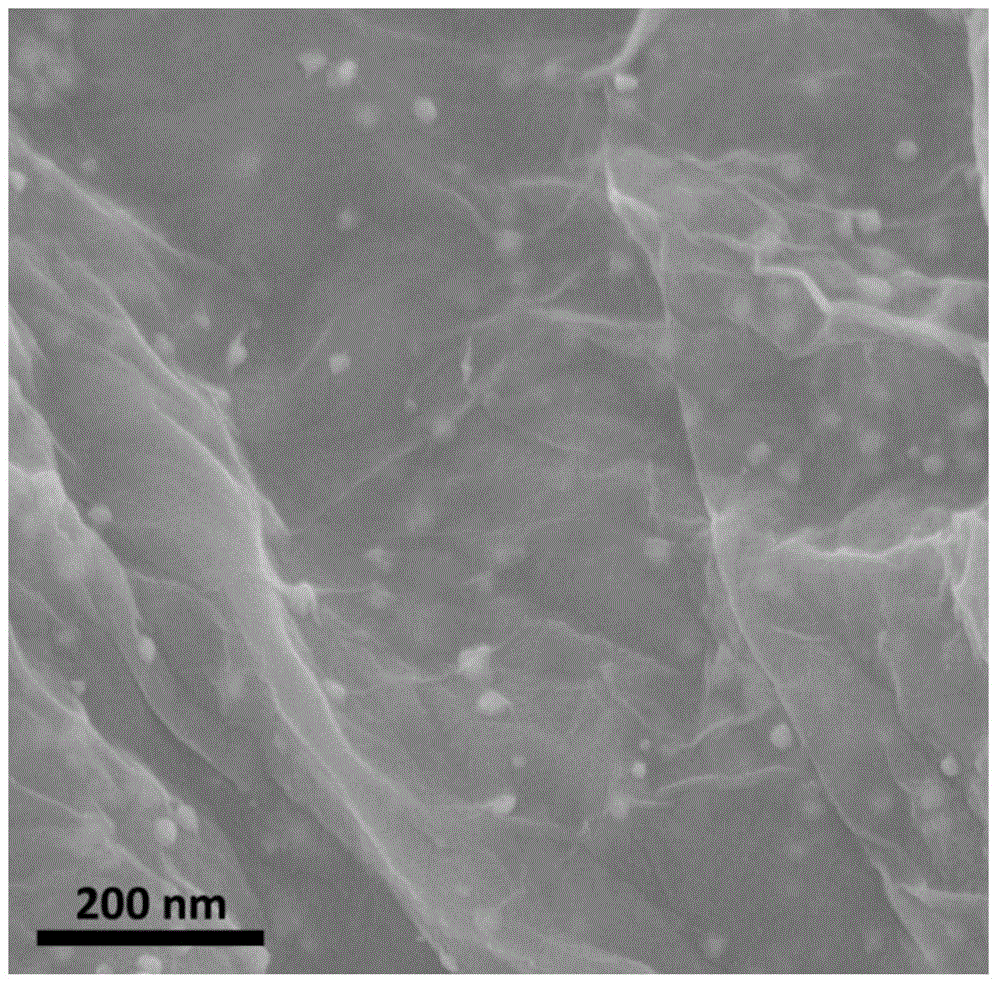

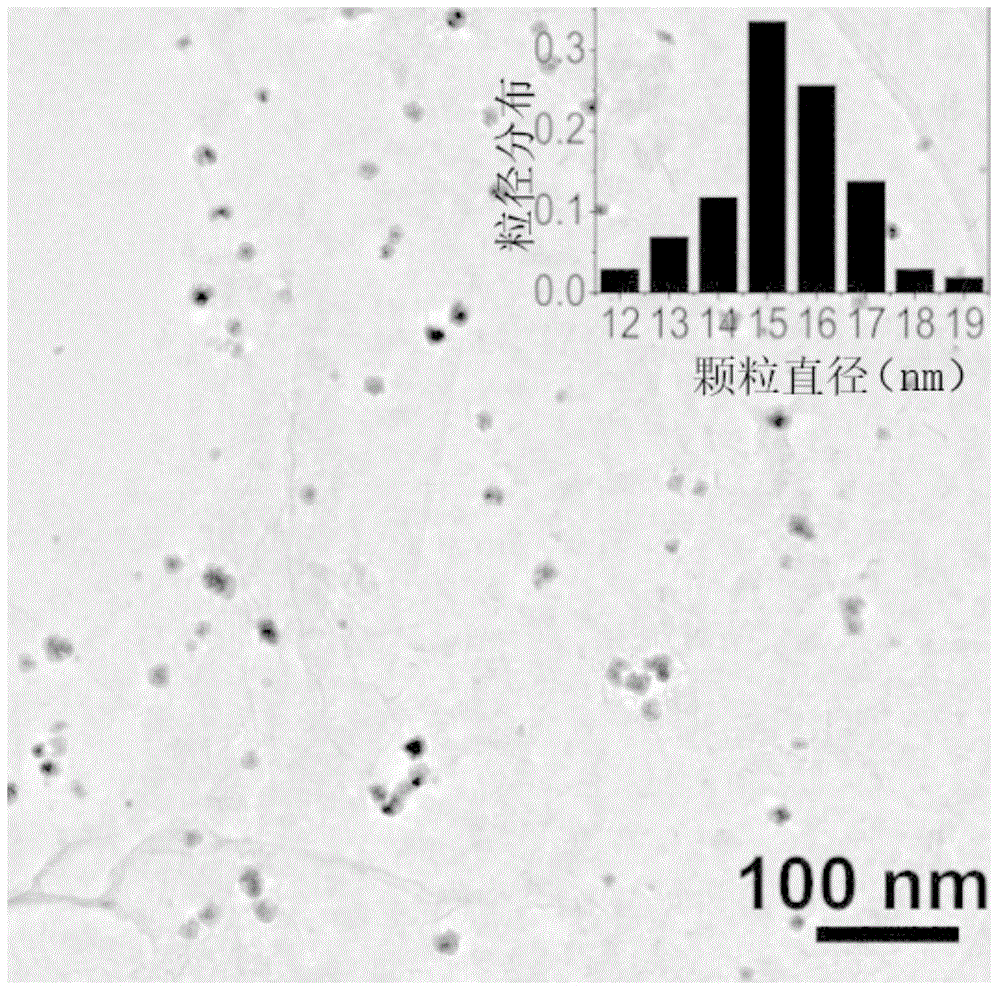

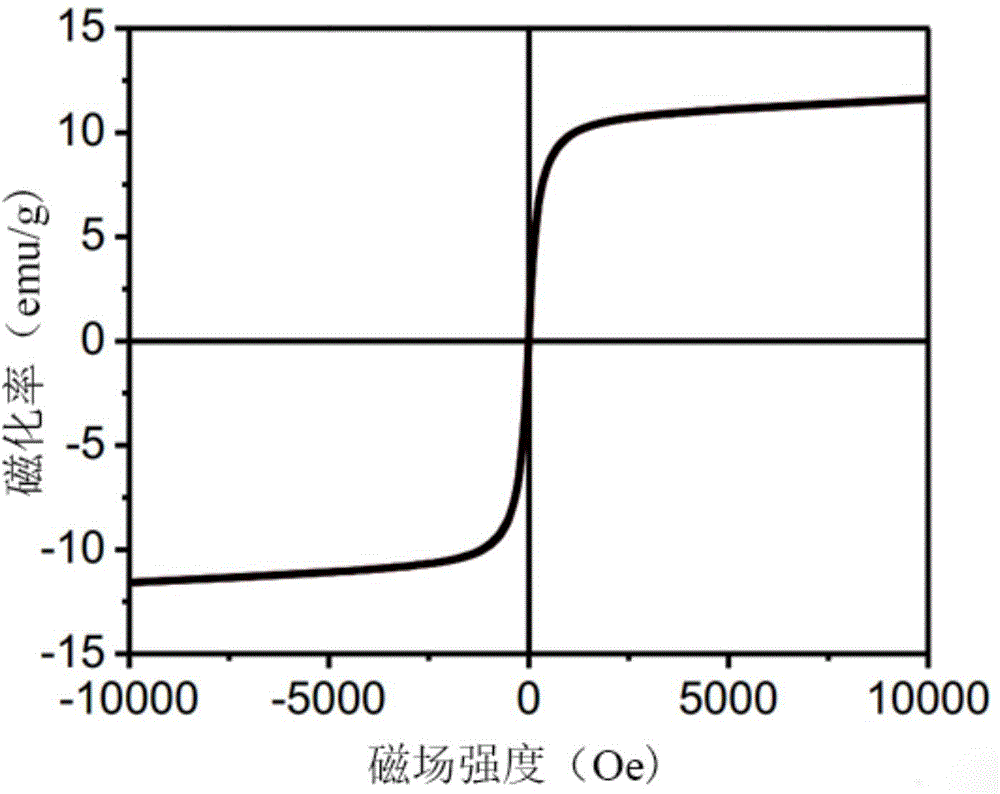

[0022] The preparation method of magnetic graphene-based platinum-nickel bimetallic catalyst of the present invention comprises the steps:

[0023] 1) In the graphene oxide aqueous solution with a concentration of 0.8-1.2 mg / mL, add tannic acid with a concentration of 3-5 mg / mL as a stabilizer at a mass ratio of graphene oxide to tannic acid of 1:1, and ultrasonically Mix and centrifuge until there is no tannic acid in the supernatant, remove the precipitate from the lower layer to obtain a graphene oxide tannic acid mixture, and prepare the obtained graphene oxide tannic acid mixture according to the mass ratio of graphene oxide and distilled water as 1:8-12 Ultrasonic dispersion in distilled water to obtain graphene oxide tannic acid composite aqueous solution;

[0024] 2) Take the graphene oxide tannic acid composite aqueous solution prepared in step 1), and add graphene oxide single Adding a platinum metal ion solution with a platinum metal ion concentration of 1 to 2 mmo...

specific example

[0028] First make graphene oxide solution:

[0029] Cool 230mL of concentrated sulfuric acid with a mass fraction of 98% to 0-5°C, add 10g of graphite and 5g of sodium nitrate, and stir for 30min at 0-5°C. Add 30g of potassium permanganate, the temperature of the reaction system should not exceed 20°C when adding, after the addition is complete, set the reaction temperature at 35°C and continue stirring for 30 minutes, add 460mL of water, raise the temperature to 98°C and continue stirring for 15 minutes, add warm water, and The mixed solution was diluted to 1400 mL, and 10 mL of 3% hydrogen peroxide was added to remove unreacted potassium permanganate. The mixed solution was filtered under reduced pressure, washed with 500mL of 1M dilute hydrochloric acid, and then washed with 1000mL of deionized water, and then centrifuged at 10000r / min to collect the precipitate and dispersed in water to prepare a graphene oxide aqueous solution.

Embodiment 1

[0031] Take 100 mL of graphene oxide aqueous solution with a concentration of 0.8 mg / mL, add 20 mL of tannic acid aqueous solution with a concentration of 4 mg / mL, ultrasonically disperse for 30 minutes, fully mix graphene oxide and tannic acid, and centrifuge to remove the lower layer of precipitate to obtain dehydration The final graphene oxide / tannic acid mixture was ultrasonically dispersed in 100 mL of distilled water. In the prepared graphene oxide / tannic acid aqueous solution, add 20mL concentration of 1mmol / L chloroplatinic acid and 33mL concentration of 12mmol / L nickel sulfate aqueous solution, dropwise add 1mol / L sodium hydroxide aqueous solution until the pH is 9 , add 2.64mL of ascorbic acid aqueous solution with a concentration of 0.3mmol / mL, stir and react at 25°C for 30min, centrifuge and wash with deionized water until the pH of the supernatant is 7, take the lower layer and freeze-dry at -50°C to obtain magnetic graphite Alkenyl platinum-nickel bimetallic cata...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com