Nanoporous copper-silver supported manganese dioxide electrode sheet and preparation method thereof

A manganese dioxide electrode and nanoporous copper technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, can solve the problems of easy harm to the human body, complicated preparation process, and unfriendly environment, and achieve specific capacitance The effect of increasing the value, avoiding poor dispersion, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

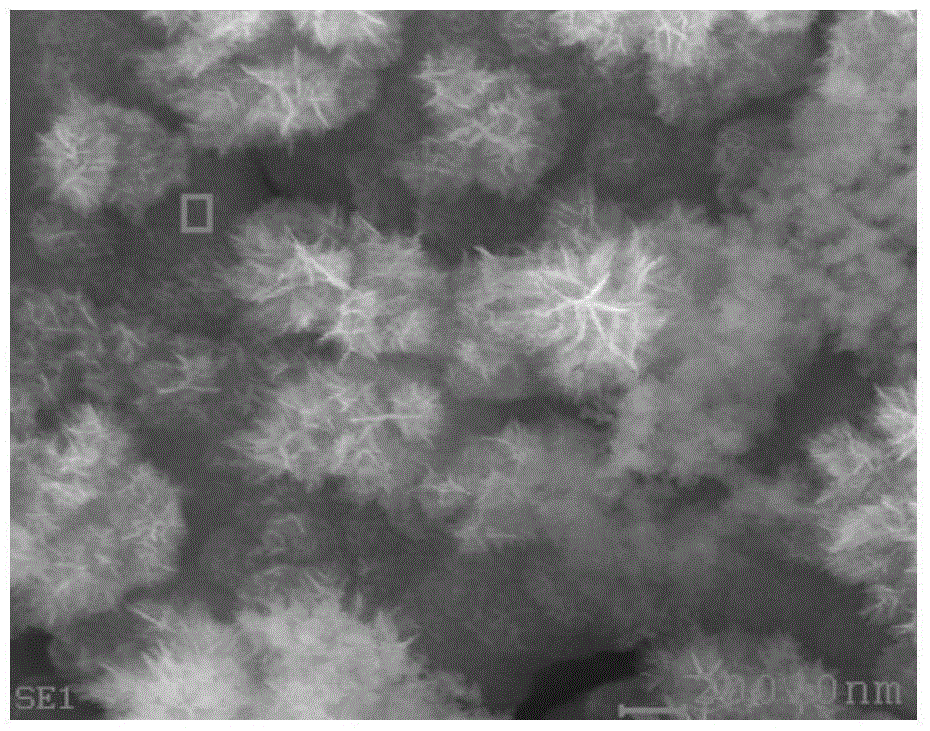

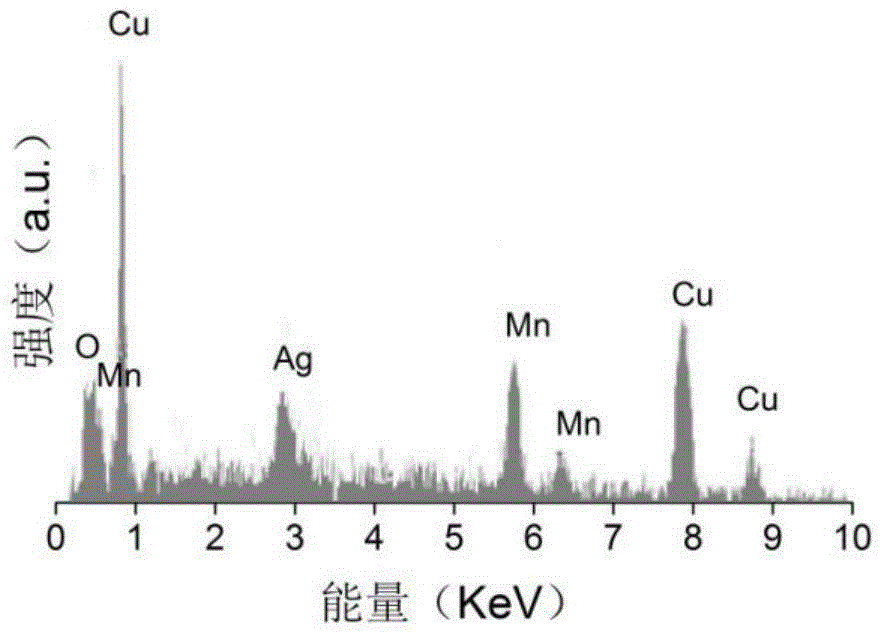

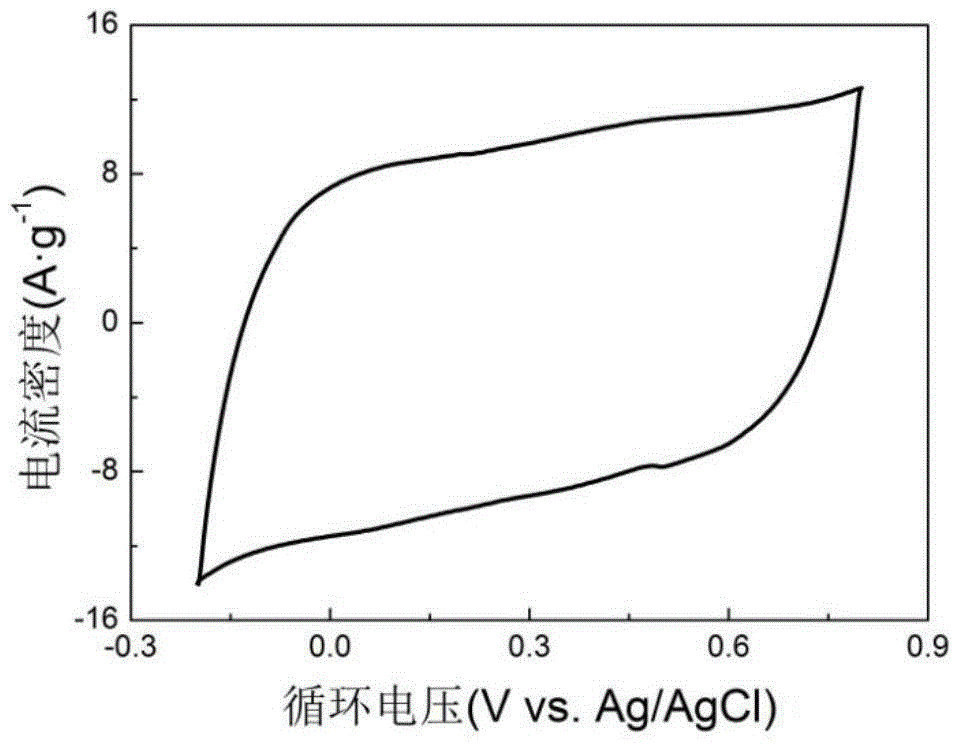

Image

Examples

Embodiment 1

[0037]According to the mass percent of each element in the target alloy: Cu is 45%, Zr is 45%, Ag is 10%, and the broken copper sheet (7.110g) that purity is 99.9wt%, zirconium particle (10.207g) and silver particle (2.682g) mixed to obtain the master alloy raw material; then the master alloy raw material is placed in a vacuum arc melting furnace, and 20g of pure titanium with a purity of 99.9wt% is added for melting as an oxygen-scavenging material, and then under the protection of argon, repeated melting for 5 Sub-master alloy (the master alloy needs to be turned every time), about 60 seconds each time, to ensure the uniformity of the alloy structure. Cu can be obtained with furnace cooling 45 Zr 45 Ag 10 alloy ingot.

[0038] Remove the surface oxide skin from the obtained alloy ingot, divide it into suitable sizes and put it into a quartz test tube, and put it into a quartz test tube at 8.0×10 -4 Under the vacuum degree of Pa, the alloy ingot is heated to melt, and the...

Embodiment 2

[0049] According to the mass percent of each element in the target alloy: Cu is 45%, Zr is 45%, Ag is 10%, the copper sheet (7.110g) that purity is 99.9wt%, zirconium grain (10.207g) and silver grain ( 2.682g) were mixed to obtain the master alloy raw material; then the master alloy raw material was placed in a vacuum arc melting furnace, and 20g of pure titanium with a purity of 99.9wt% was used as the oxygen-scavenging material, and under the protection of argon, the melting was repeated 5 times (each It is necessary to turn over the master alloy), about 60 seconds each time, to ensure the uniformity of the alloy structure. Cu can be obtained with furnace cooling 45 Zr 45 Ag 10 alloy ingot.

[0050] Remove the surface oxide skin from the obtained alloy ingot, divide it into suitable sizes and put it into a quartz test tube, and put it into a quartz test tube at 8.0×10 -4 Under the vacuum degree of Pa, the alloy ingot is heated to melt, and then the molten alloy is quickl...

Embodiment 3

[0056] According to the mass percent of each element in the target alloy: Cu is 45%, Zr is 45%, Ag is 10%, the copper sheet (7.110g) that purity is 99.9wt%, zirconium grain (10.207g) and silver grain ( 2.682g) were mixed to obtain the master alloy raw material; then the master alloy raw material was placed in a vacuum arc melting furnace, and 20g of pure titanium with a purity of 99.9wt% was used as the oxygen-scavenging material, and under the protection of argon, the melting was repeated 5 times (each It is necessary to turn over the master alloy), about 60 seconds each time, to ensure the uniformity of the alloy structure. Cu can be obtained with furnace cooling 45 Zr 45 Ag 10 alloy ingot.

[0057] Remove the surface oxide skin from the obtained alloy ingot, divide it into suitable sizes and put it into a quartz test tube, and put it into a quartz test tube at 8.0×10 -4 Under the vacuum degree of Pa, the alloy ingot is heated to melt, and then the molten alloy is quickl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com