A method for manufacturing and installing steel-plastic composite pipelines for oilfield gathering and transportation

A steel-plastic composite pipe and steel-plastic composite technology, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of fluid leakage, steel-plastic composite pipe strength and anti-corrosion weakening, and achieve pipeline installation Convenience, reduced gathering and transportation maintenance, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

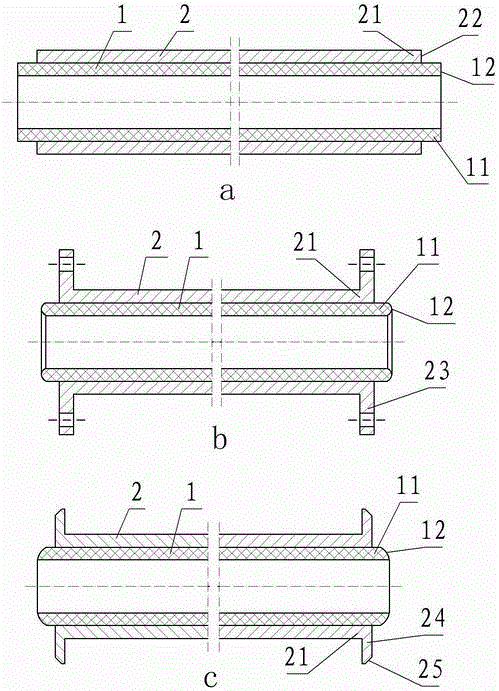

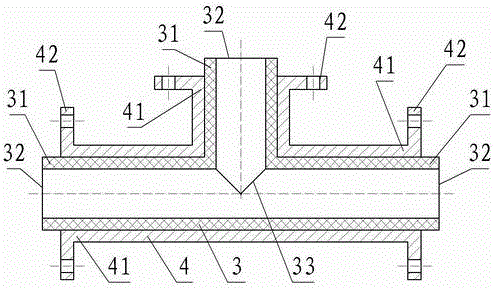

[0044] Selection of materials: ⑴Select seamless steel pipes with outer diameter φ114mm, inner diameter φ97mm (wall thickness 8.5mm), length 9500mm, and pipe fittings such as tee and elbow with the same inner diameter, including those with flanges and collars for welding connection. For seamless steel pipes, the mouths of tees and elbows are prefabricated with flanges or collars for welding connection; ⑵The plastic pipe is made of high-density polyethylene (HDPE) with an outer diameter of φ102, which is about 5% larger than the inner diameter of the steel pipe, and the wall thickness is 9mm; ⑶ Steel pipe clamps are seamless steel pipes with outer diameter φ133mm, inner diameter φ121mm (wall thickness 6mm), and length 320mm; ⑷ epoxy resin adhesive, etc.

[0045] step

[0046] 1) Preparation of steel-plastic composite pipe: reference figure 1 The high-density polyethylene pipe 1 with a length of 9560mm is heated to 45°C for 10 minutes and then reduced to an outer diameter of 95mm (abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com