Preparation method of phase change microcapsule with graphene-modified wall material

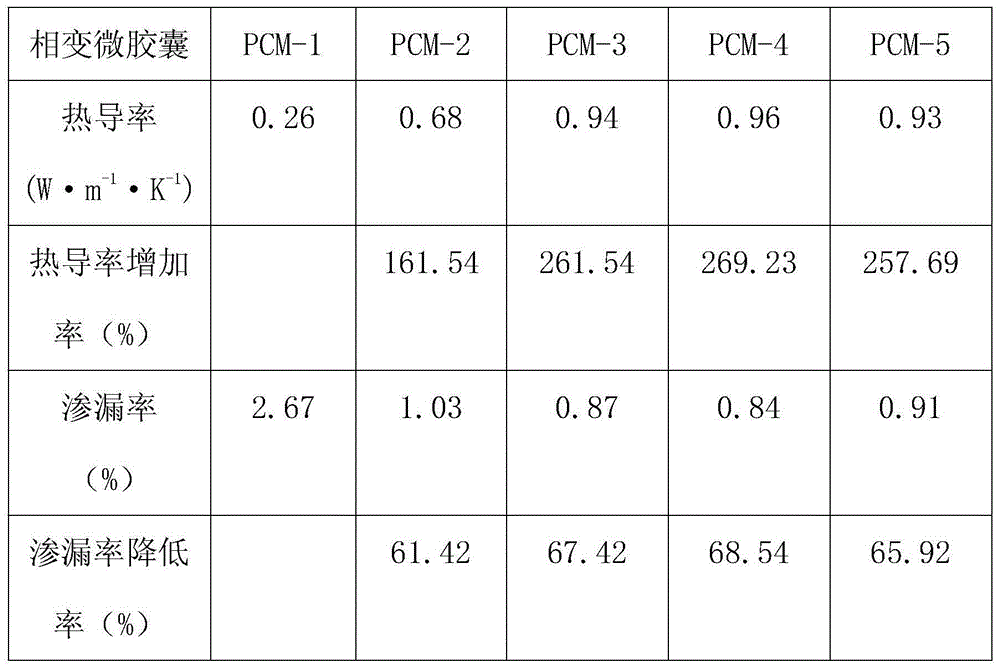

A graphene modification, phase change microcapsule technology, applied in microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., can solve the problems of low thermal conductivity and high graphene permeability, and achieve low leakage rate , the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of Unmodified Melamine Resin Phase Change Microcapsules

[0033] (1) Preparation of prepolymer

[0034] Weigh 4.0 g of melamine and 8.5 g of 37% formaldehyde solution, add 15 mL of distilled water, adjust the pH to 9 with triethanolamine, and stir for 50 min at 70° C. to obtain a melamine-formaldehyde resin prepolymer.

[0035] (2) Emulsification of phase change materials

[0036] Weigh 5.0 g of styrene-maleic anhydride copolymer (SMA) and 1.0 g of NaOH, add 250 mL of distilled water, heat to dissolve, and obtain an emulsifier solution. Add 40 g of paraffin with a melting point of 42° C., adjust the pH of the system to 4.5 with citric acid, and heat at 70° C. to melt the paraffin. Then emulsify in a high-shear emulsifier, the emulsification conditions are: rotation speed 3000r / min, emulsification time 10min, to obtain paraffin wax emulsion.

[0037] (3) Preparation of phase change microcapsules

[0038] Under the condition of stirring in a water bath at ...

Embodiment 2

[0040] Preparation of graphene-modified melamine resin phase change microcapsules

[0041] (1) Preparation of graphene oxide solution

[0042] Weigh 25.0 mg of graphite oxide, add 50.0 mL of deionized water, stir, and sonicate for 1 h to prepare a 0.5 mg / mL graphene oxide solution.

[0043] (2) Preparation of graphene modified wall material prepolymer

[0044] Weigh 4.0g of melamine and 8.5g of formaldehyde solution with a concentration of 37%, add 15mL of distilled water, adjust the pH to 9 with triethanolamine, stir and react at 70°C for 30min, then add 8mL of graphene oxide solution with a concentration of 0.5mg / mL (the added mass of graphene oxide accounts for 1‰ of the mass of melamine) to continue the reaction for 20 minutes to obtain a graphene-modified melamine-formaldehyde resin prepolymer.

[0045](3) Emulsification of phase change materials

[0046] Weigh 5.0 g of styrene-maleic anhydride copolymer (SMA) and 1.0 g of NaOH, add 250 mL of distilled water, heat to d...

Embodiment 3

[0050] Preparation of graphene-modified urea-formaldehyde resin phase change microcapsules

[0051] (1) Preparation of graphene oxide solution

[0052] Weigh 50.0 mg of graphite oxide, add 50 mL of deionized water, stir, and sonicate for 1 h to prepare a 1 mg / mL graphene oxide solution.

[0053] (2) Preparation of graphene modified wall material prepolymer

[0054] Weigh 4.5g of urea and 8.5g of formaldehyde solution with a concentration of 37%, add 15mL of distilled water, adjust the pH to 8 with triethanolamine, stir and react at 70°C for 20min, then add 22.5mL of graphene oxide solution with a concentration of 1mg / mL (The added mass of graphene oxide accounts for 5‰ of the mass of urea) to continue the reaction for 30 minutes to obtain a graphene-modified urea-formaldehyde resin prepolymer.

[0055] (3) Emulsification of phase change materials

[0056] Weigh 5 g of styrene-maleic anhydride copolymer (SMA) and 1.0 g of NaOH, add 250 mL of distilled water, and heat to diss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com