A method of manufacturing a monolithic bipolar membrane

The technology of a bipolar membrane and a manufacturing method, which is applied in the field of preparation of membrane separation materials, can solve the problems that the base membrane cannot be obtained by impregnation, and the bipolar membrane cannot be further prepared, and achieves easy large-scale industrial production, mechanical The effect of high strength and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

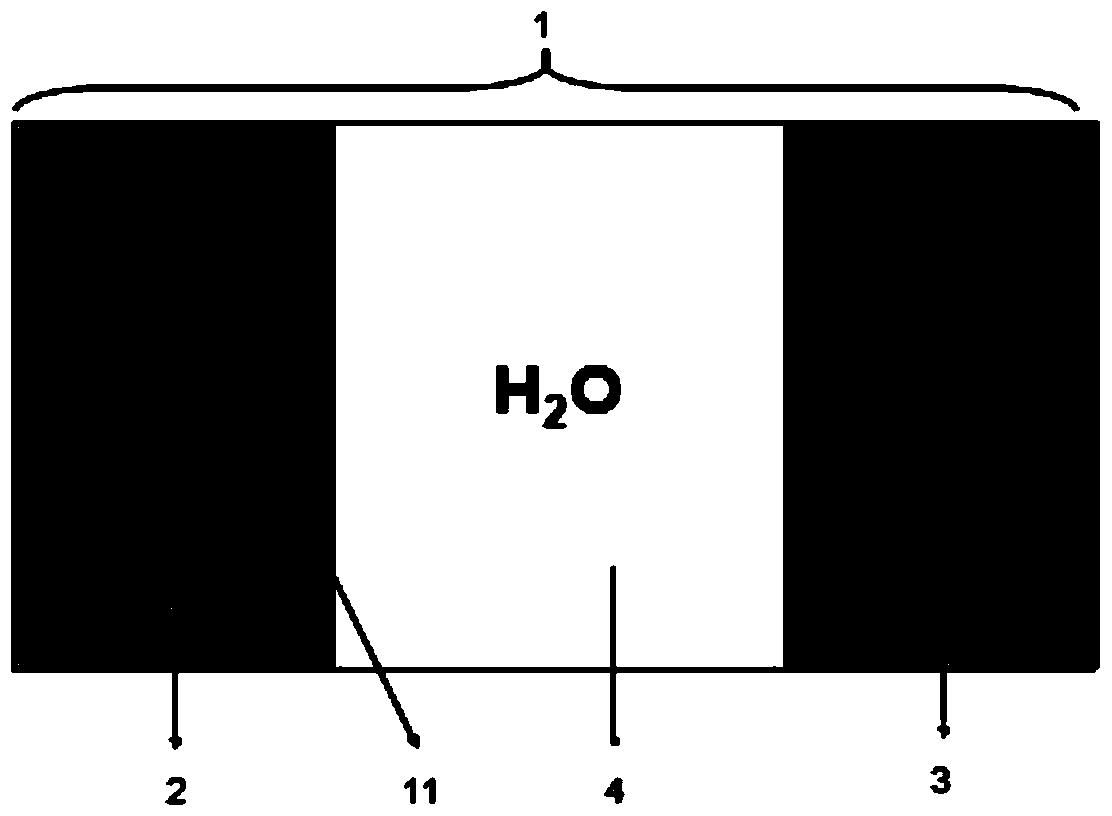

Image

Examples

Embodiment 1

[0045] Cut a polyethylene film with a thickness of 0.15mm into a size of 400mm*800mm, alternately stack it with glass cloth of the same size to form a film stack, and immerse the film stack in a container filled with styrene-divinylbenzene (the content of divinylbenzene is 5% of the mass fraction of styrene) in the rectangular aluminum container of the monomer solution, through high-purity nitrogen deoxygenation, and seal. Then place the container in In the gamma source room, irradiate at room temperature with a total dose of 5 kilograys (K Gray). The membrane stack was taken out and separated to obtain a grafted membrane (abbreviated as basement membrane), with a grafting degree of 55%.

[0046] Then put one side of the base film close to the ceramic sheet and fix it tightly, put them together in concentrated sulfuric acid for single-sided sulfonation, sulfonation conditions: sulfonate at 70°C for 6 hours, cool, take out, and separate , to obtain a positive film with a pos...

Embodiment 2

[0049] A blended film (with an elastomer content of 45 wt%) of polyethylene with a thickness of 0.15mm and an ethylene-octene copolymer elastomer (containing 45 wt% of octene) was used as the raw material film (ie, the base film). Cut the 0.15mm thick polyethylene and ethylene-octene copolymer elastomer (containing octene 45wt%) blended film (elastomer content is 45wt%) into a size specification of 400mm*800mm, and glass cloth of the same size specification Alternately stacked into a membrane stack, and the membrane stack is immersed in a rectangular aluminum container filled with styrene-divinylbenzene (divinylbenzene content is 8% of the mass fraction of styrene) monomer solution, through high-purity nitrogen deoxygenation, and sealed. Then place the container in In the gamma source room, irradiate at room temperature with a total dose of 10 kilograys (K Gray). The membrane stack was taken out and separated to obtain a grafted membrane (abbreviated as basement membrane), ...

Embodiment 3

[0053] Adopt polypropylene film to make basement membrane, operating procedure is according to embodiment 1. Except not adding divinylbenzene in the monomer solution, others are the same as embodiment 1. The grafting degree of the base film is 65%, the positive layer capacity of the bipolar membrane is 1.76 meq / g dry film, the negative layer capacity is 0.72 meq / g dry film, and the water content is 36%. The transmembrane voltage is 2.0V, and the burst strength is 0.24MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bursting strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| bursting strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com