Cardanol unsaturated resin monomer and preparation method thereof

A technology of resin monomer and cardanol, applied in cardanol unsaturated resin monomer and its preparation, in the field of cardanol unsaturated resin, can solve the problems of poor mechanical properties and solvent resistance of unsaturated resin, and achieve excellent mechanical properties. Performance and water resistance, good water resistance, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

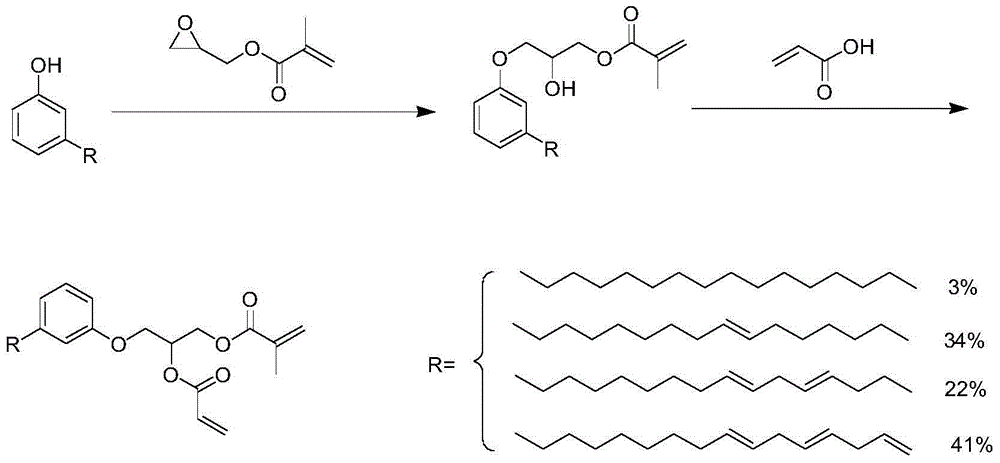

[0015] Accurately weigh 1000.0g of cardanol into the reactor, add 1.0g of hydroquinone, blow in nitrogen, stir and heat up to 80°C, add 10.0g of N,N-dimethylbenzylamine, increase the stirring speed, and slowly Add 473.5g of glycidyl methacrylate (GMA) dissolved in a small amount of hydroquinone (0.5g) dropwise. After the dropwise addition, the reaction temperature is slowly raised to 120°C. After 4 hours, it is cooled rapidly and the finished product is collected to obtain cashew nuts. Phenolic polymerized glycidyl methacrylate (CD-p-GMA).

Embodiment 2

[0017] Accurately weigh 885.0g CD-p-GMA, 144.0g acrylic acid, 1.7g hydroquinone and 1.0g cation exchange resin, heat up to 120°C, react for 5h, the measured acid value is less than 10mgKOH / g, stop the reaction, and vacuumize , cooling, and filtering to obtain acrylic acid-modified cardanol polymerized glycidyl methacrylate (AC-m-CD-p-GMA). (Main component molecular weight data: (m+H) + = 485.4, 483.4, 481.4)

Embodiment 3

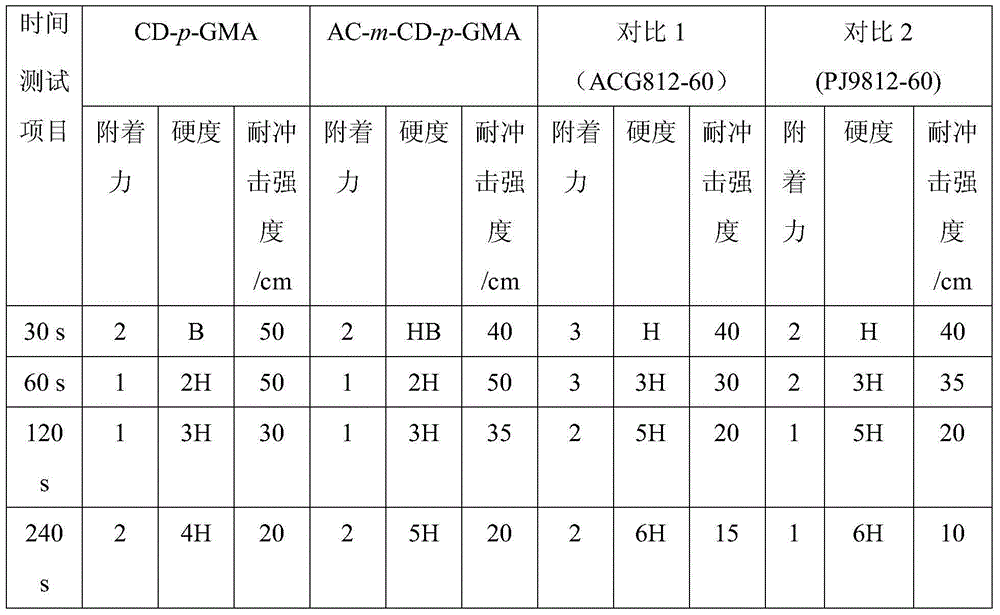

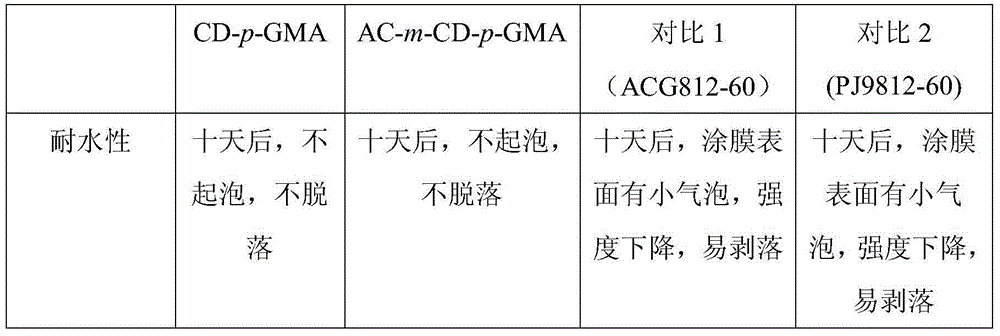

[0019] Add 3wt% of the photoinitiator benzoin dimethyl ether to the prepared two kinds of cardanol-based unsaturated resin monomers and a certain pure acrylic resin, mix evenly and apply it on the transparent glass with a 50 μm film applicator, and then apply it Put it into Intelli Ray 400UV curing box, the light radiation intensity is 100mW·cm -2 , Investigate the coating film performance of monomer curing in different light curing time of 30, 60, 120s, and 240s. It can be seen from Table 1 that the coating film hardness of both CD-p-GMA and AC-m-CD-p-GMA increased sharply within 60s, and reached the optimal value of mechanical properties around 60s. Continue to prolong the irradiation time, the hardness continues to rise, but the speed slows down, while the impact resistance drops sharply, and the adhesion also drops. This is because the longer the UV radiation time, the more complete the photocuring, so the greater the crosslinking density of the cured film, the higher the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com