Preparation method of porous organic-inorganic hybrid silica microspheres

A technology of hybrid silica gel and silica gel microspheres, applied in the directions of silica, silica, etc., can solve the problems of poor spherical shape of microspheres, uneven spherical shape of microspheres, and difficulty in achieving chromatographic fixation and equality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of hybrid prepolymer: Add 58.5g of polyethylsilicate-40, 7.5g of phenyltriethoxysilane and 17.7mL of absolute ethanol into a 100mL three-necked flask, and mechanically Stir to combine well. Add 3mL of hydrochloric acid dropwise, the concentration of hydrochloric acid is 0.1mol / L, continue to stir for 30min, and rotate under reduced pressure at 80°C and -0.08MPa for 2h to remove ethanol, hydrochloric acid and other substances in the system.

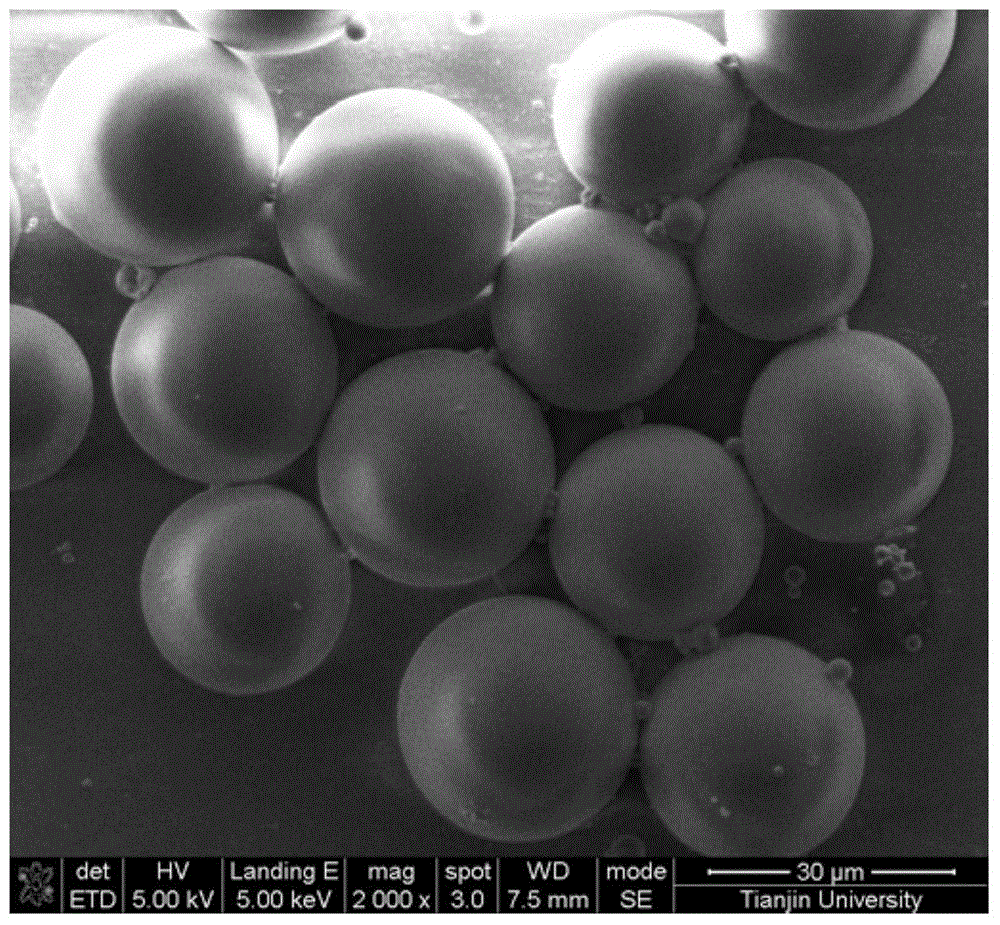

[0029] (2) Preparation of hybrid silica gel microspheres: Add 150mL of water, 50mL of isopropanol, 2.0g of Triton-100, and 0.3g of sodium dodecyl sulfate into a 500mL three-neck flask as the continuous phase, and weigh the above prepared 50.0 g of the prepolymer was added into the continuous phase under mechanical stirring at 1000 rpm to form an O / W emulsion. After stirring for 5 minutes, ammonia water with a concentration of 2% by volume was added to catalyze the secondary hydrolysis and condensation reaction, and s...

Embodiment 2

[0032] (1) Preparation of hybrid prepolymer: Add 52.0g polyethylsilicate-40, 15.0g phenyltriethoxysilane and 17.7mL absolute ethanol to a 100mL three-necked flask, and machine in a 30°C water bath at 700rpm Stir to combine well. Add 3mL of hydrochloric acid dropwise, the concentration of hydrochloric acid is 0.1mol / L, continue to stir for 30min, and rotate under reduced pressure at 80°C and -0.08MPa for 2h to remove ethanol, hydrochloric acid and other substances in the system.

[0033] (2) Preparation of hybrid silica gel microspheres: the steps are the same as step (2) in Example 1.

[0034] (3) Post-treatment of the hybrid silica gel microspheres: the steps are the same as the step (3) in Example 1.

Embodiment 3

[0036](1) Preparation of hybrid prepolymer: Add 58.5g of polyethyl silicate-40, 7.3g of n-octyltrimethoxysilane and 17.7mL of absolute ethanol into a 100mL three-necked flask. Stir to combine well. Add 3mL of hydrochloric acid dropwise, the concentration of hydrochloric acid is 0.1mol / L, continue to stir for 30min, and rotate under reduced pressure at 80°C and -0.08MPa for 2h to remove ethanol, hydrochloric acid and other substances in the system.

[0037] (2) Preparation of hybrid silica gel microspheres: the steps are the same as step (2) in Example 1.

[0038] (3) Post-treatment of the hybrid silica gel microspheres: the steps are the same as the step (3) in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com