A kind of preparation method of graphene

A graphene and graphite flake technology, applied in the field of graphene, can solve the problems of difficulty in mass preparation, small amount of graphene products, and high manufacturing cost, and achieves reduction of potential safety hazards and environmental pollution, small environmental pollution, and reduced difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

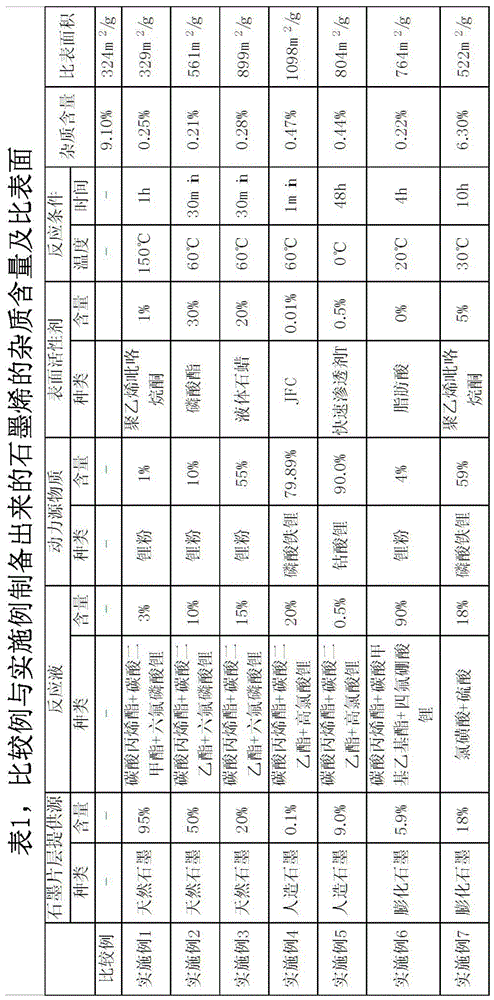

Examples

Embodiment 1

[0035] Preparation of reaction slurry: natural graphite is selected as the source of graphite flakes, and its mass accounts for 95% of the mass of reaction slurry;

[0036] Propylene carbonate: a mixed solution of dimethyl carbonate=1:1 as a solvent, a solution of 1mol / L lithium hexafluorophosphate as a solute as an electrolyte (reaction solution), and its mass accounts for 3% of the mass of the reaction slurry;

[0037] Select polyvinylpyrrolidone as the surfactant, and its quality accounts for 1% of the reaction slurry quality;

[0038] Lithium metal powder is the power source material, and its quality accounts for 1% of the reaction slurry quality;

[0039] After that, it is added into the reactor, fully stirred and mixed to obtain a reaction slurry.

[0040] Preparation of graphene puree: control the temperature of the reactor at 150°C, and stir fully for 1 hour, so that the natural graphite particles and the lithium metal powder are in full contact (forming an electronic...

Embodiment 2

[0043] Different from Embodiment 1, this embodiment includes the following steps:

[0044] Preparation of reaction slurry: natural graphite is selected as the source of graphite flakes, and its mass accounts for 50% of the mass of reaction slurry;

[0045] Propylene carbonate: diethyl carbonate = 1:1 mixed solution as solvent, 1.2mol / L lithium hexafluorophosphate as solute solution as electrolyte (reaction solution), its mass accounts for 10% of the reaction slurry mass;

[0046] Select phosphoric acid ester as surfactant, its quality accounts for 30% of reaction slurry quality;

[0047] Lithium metal powder is the power source material, and its quality accounts for 10% of the reaction slurry quality;

[0048] After that, it is added into the reactor, fully stirred and mixed to obtain a reaction slurry.

[0049] Preparation of graphene puree: control the temperature of the reactor at 60°C, and fully stir for 30 minutes, so that the natural graphite particles and the lithium ...

Embodiment 3

[0052] Different from Embodiment 1, this embodiment includes the following steps:

[0053] Preparation of reaction slurry: select natural graphite as the source of graphite flakes, and its mass accounts for 20% of the mass of reaction slurry;

[0054] Propylene carbonate: a mixture of diethyl carbonate=1:1 as a solvent and a solution of 1.2mol / L lithium hexafluorophosphate as a solute as an electrolyte (reaction solution), whose mass accounts for 15% of the mass of the reaction slurry;

[0055] Select liquid paraffin to be tensio-active agent, its quality accounts for 10% of reaction slurry quality

[0056] Lithium metal powder is the power source material, and its quality accounts for 55% of the reaction slurry quality;

[0057] After that, it is added into the reactor, fully stirred and mixed to obtain a reaction slurry.

[0058] Preparation of graphene puree: control the temperature of the reactor at 60°C, and fully stir for 30 minutes, so that the natural graphite partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com