Photolysis oxidation oil fume purifier

A technology for oxidizing oil fumes and purifiers, applied in chemical instruments and methods, separation of dispersed particles, combined devices, etc., can solve problems affecting ultraviolet penetration rate and irradiation intensity, health impact of operators, and failure to effectively remove grease particles, etc. , to achieve the effect of ensuring the penetration rate and irradiation intensity, convenient observation and cleaning, and better disinfection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

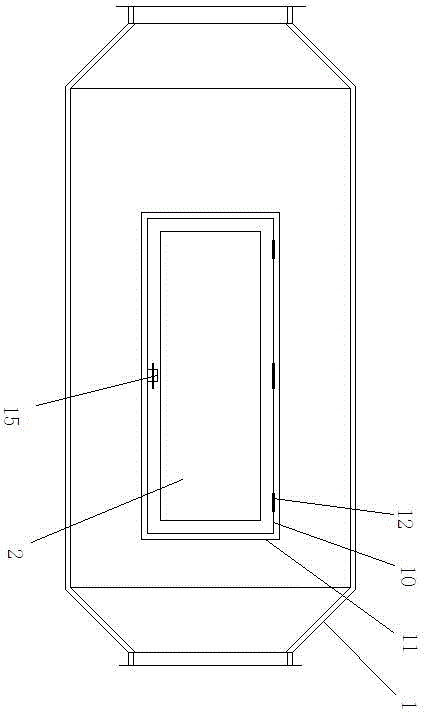

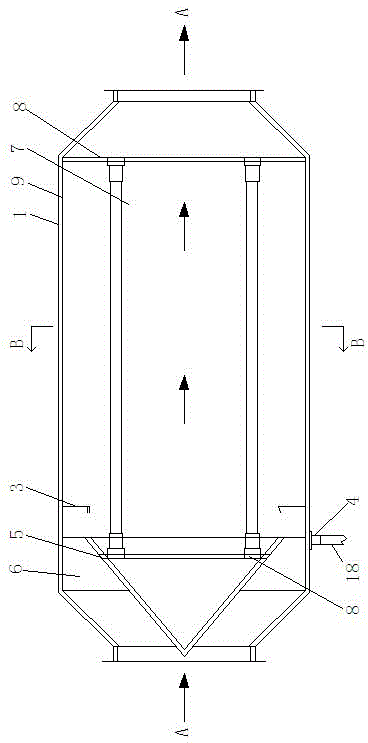

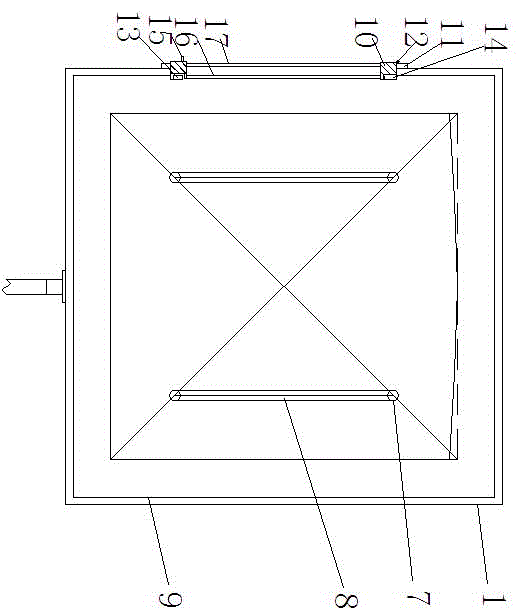

[0024] exist figure 1 , 2 , In the embodiment shown in 3 and 4, it is composed of the main body of the purifier, the oil filter system, the photolysis oxidation system, the ventilation pipeline system and the control system. The main body of the purifier consists of the purifier shell (1), the maintenance observation door (2) set on the front of the purifier shell (1) and the collector set between the lower part of the purifier shell (1) and the dirt separation plate (3). Sewage port (4); the oil filter system is composed of conical guide body (5), guide plate (6) and dirt separation plate (3) arranged at the inlet of the purifier; the photolysis oxidation system is composed of conical guide The high-energy UV ultraviolet lamp (7) inside the fluid (5), the lamp tube mounting frame (8) and the coating on the conical guide body (5), the purifier housing (1), the dirt separation plate (3), and the lamp The tube mount (8) consists of a titanium dioxide coating (9).

[0025] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com