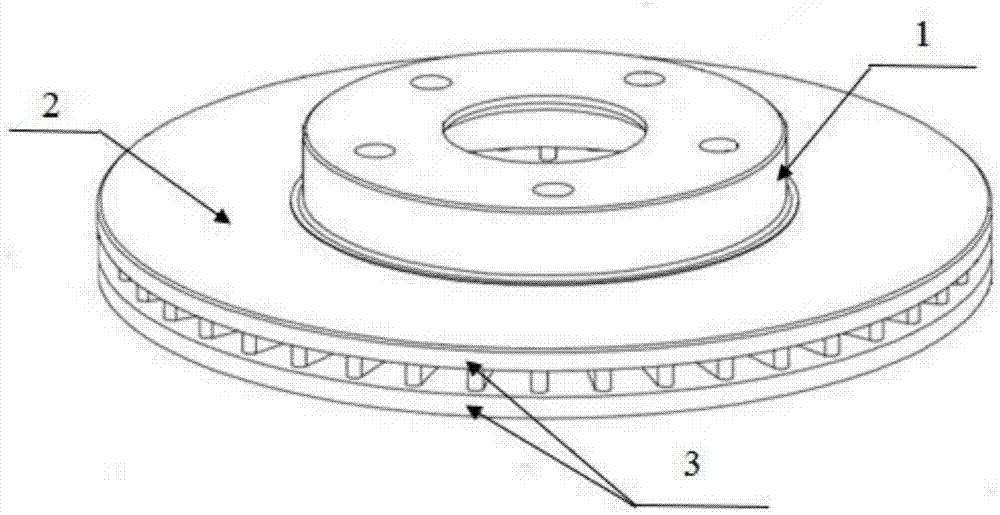

Automobile brake disc anti-corrosion treatment method

A technology for automobile braking and anti-corrosion treatment, which is applied in anti-corrosion coatings, pretreatment surfaces, and devices for coating liquids on surfaces. The effect of excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A. First, clean and phosphate the brake disc of the car. Specifically include: immerse the brake disc in acetone solvent for 20 minutes to remove surface oil. Then immerse the brake disc in an ultrasonic pool filled with acetone, and perform ultrasonic treatment for 10 minutes to remove internal oil stains. Then immerse the brake disc in the dilute sulfuric acid pool and rinse for 5 minutes. Then the workpiece was immersed in a pure water pool for 5 minutes by ultrasonic treatment. Then immerse the workpiece in a commercially available phosphating solution whose temperature is kept at 40°C±2°C, and rinse for 20 minutes. Dry the workpiece at 200°C.

[0022] B. Then use the graphene coating to spray the pre-treated qualified brake discs. The steps are as follows: mix components A and B of the graphene coating at a ratio of 1:1 (mass ratio), and stir at a medium speed for 5 hours. Filter with 80-mesh gauze. After passing the test, use an automatic spraying line to eve...

Embodiment 2

[0027] A. First, clean and phosphate the brake disc of the car. Specifically include: immerse the brake disc in trichlorethylene solvent for 20 minutes to remove surface oil. Then immerse the brake disc in an ultrasonic pool filled with trichlorethylene, and perform ultrasonic treatment for 10 minutes to remove internal oil stains. Then immerse the brake disc in a commercially available pickling pool and rinse for 5 minutes. Then the workpiece was immersed in a pure water pool for 5 minutes by ultrasonic treatment. Then immerse the workpiece in a commercially available phosphating solution whose temperature is kept at 40°C±2°C, and rinse for 20 minutes. Dry the workpiece at 200°C.

[0028] B. Then use the graphene coating to spray the pre-treated qualified brake discs. The steps are as follows: mix components A and B of the graphene coating at a ratio of 1:1 (mass ratio), and stir at a slow speed for 12 hours. Use an 80-mesh stainless steel screen to filter. After passing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com