A waste heat recovery multi-heat source composite heat pump water supply system

A technology for water supply system and waste heat recovery, applied in heat recovery systems, solar heating systems, heating devices, etc., can solve the problems of limited operating temperature range, inability to adapt to outdoor temperature, poor seasonal adaptability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

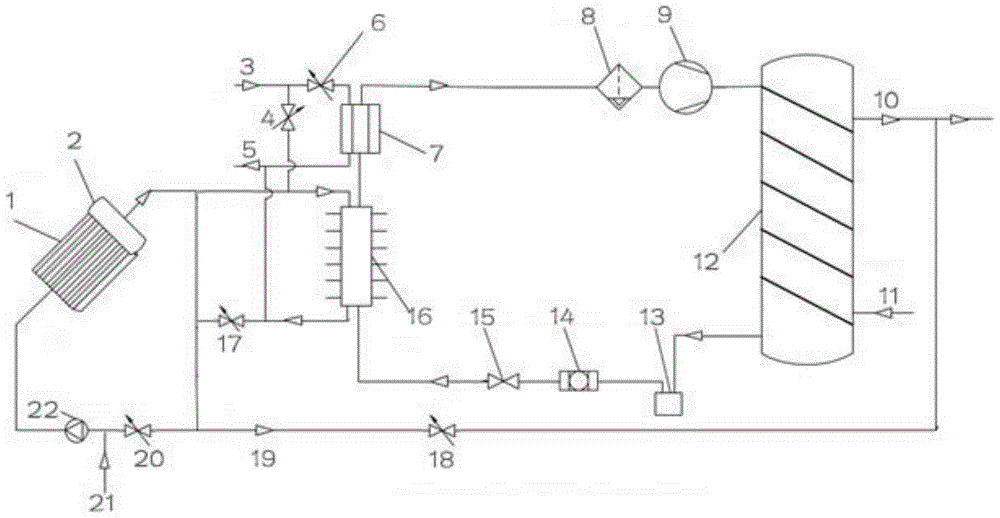

[0018] exist figure 1 Among them, a waste heat recovery multi-heat source composite heat pump water supply system consists of three subsystems, namely solar heat collection water supply system, waste heat auxiliary system, air source heat pump water supply system, waste heat auxiliary system and air source heat pump water supply system. The system is connected in parallel, which is used to realize the preheating of the working medium of the heat pump system by using the waste heat resources. At the same time, the waste heat auxiliary system realizes the defrosting function of the heat exchanger of the heat pump system through the valve of the side branch pipeline of the waste heat system. The solar collector water supply system can directly supply heat independently The water is connected in parallel to the air source heat pump water supply system to defrost the heat exchanger of the heat pump system. The specific connection relationship of the above three subsystems is:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com