Passive house wall bushing waterproof air tightness structure construction method

A construction method and a technology of wall-piercing pipes, which are applied to pipes, building structures, pipes/pipe joints/fittings, etc., can solve the problem that the air-tightness test of the house cannot achieve air-tightness, and affect the heat preservation, energy-saving and air-tightness of the enclosure structure To achieve the effect of improving waterproof and airtight performance, improving crack resistance and airtight performance, improving heat preservation and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

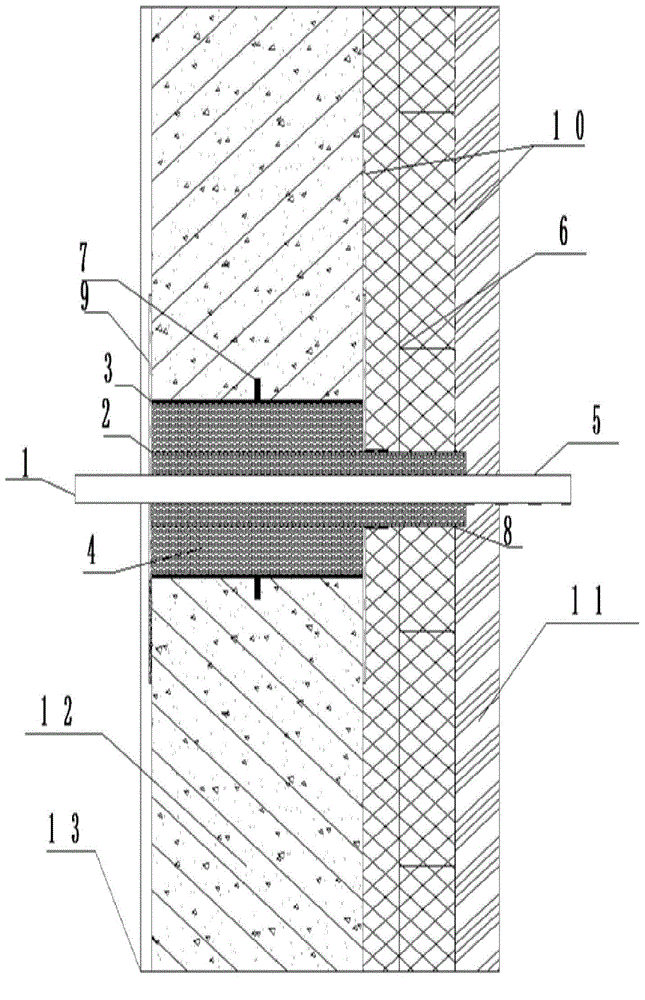

[0047] In a high-rise residential project, the wall is a reinforced concrete shear wall with a thickness of 150mm, and the heat transfer coefficient of the wall is required to be no more than 0.15 (W / m 2 K), the airtightness requirement reaches n 50 ≤ 0.6 / h requirement. Combined with the construction method of the passive house passive house through-wall pipe waterproof and airtight structure, the specific implementation is as follows:

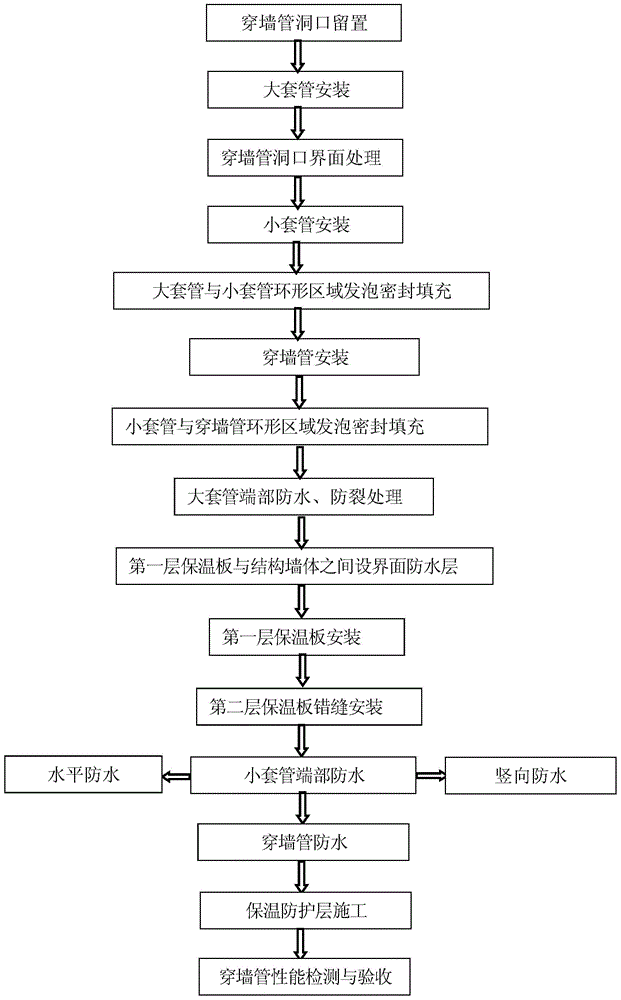

[0048] In order to achieve the comprehensive functional requirements of thermal insulation, energy saving, waterproof and airtightness of passive houses, the technical scheme adopted is: double-layer casing protection, double-layer annular foam sealing, filling and isolation double-layer sealing treatment, double-layer staggered seam insulation and energy saving, 4 water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com