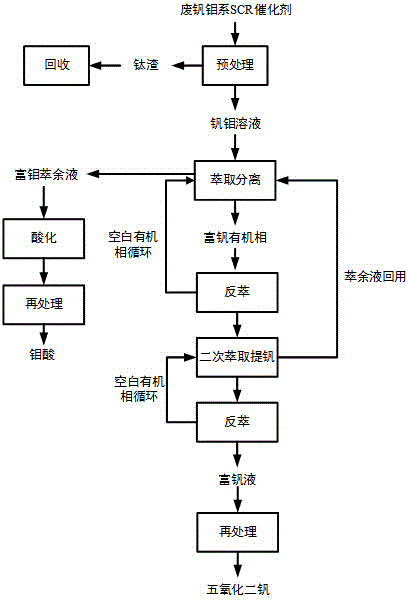

Method for separating and purifying vanadium and molybdenum of waste vanadium-molybdenum SCR (selective catalytic reduction) catalyst

An SCR catalyst and molybdenum-based technology, which is applied in the field of molybdenum separation and purification, waste vanadium-molybdenum-based SCR catalyst vanadium, can solve the problems that are not suitable for industrial applications, will change the properties of the organic phase, and cannot obtain high purity, and achieve high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The spent vanadium-molybdenum-based SCR catalyst provided by a laboratory, V 2 o 5 The content is 1.5%, MoO 3 4.5%, TiO 2 94%.

[0047] (1) Take the above spent catalyst, press m add :m metal Add additive NaOH at a ratio of = 1, then mix evenly and place in a muffle furnace to roast for conversion and removal of impurities, the roasting temperature is 600°C, and the roasting time is 3 hours; pure water is used as the leaching agent to extract vanadium and molybdenum from the roasted solid phase product, The liquid-solid ratio is 0.02L / g, the leaching temperature is 20°C, and the leaching time is 0.5h. The single-stage leaching rate of vanadium is 82%, and that of molybdenum is 72%. After filtration, the residue is recovered;

[0048] (2) Use the extraction system composed of 5% primary amine extractant JMT and kerosene as the organic phase to conduct a one-stage extraction and separation of vanadium and molybdenum in the vanadium and molybdenum leach solution, O / A=...

Embodiment 2

[0055] The spent vanadium-molybdenum-based SCR catalyst provided by a laboratory, V 2 o 5 The content is 2.1%, MO 3 3.5%, TiO 2 94.4%

[0056] (1) Take the above spent catalyst, press m add :m metal =1.2, add the additive NaCl, then mix it evenly and put it in the muffle furnace to roast for conversion and removal of impurities, the roasting temperature is 500°C, and the roasting time is 4.5h; use 1mol / L NaOH as the leaching agent, and leaching from the solid phase product after roasting For vanadium and molybdenum, the liquid-solid ratio is 0.025L / g, the leaching temperature is 25°C, the leaching time is 4h, the single-stage leaching rate of vanadium is 83%, and that of molybdenum is 74%. After filtering, the residue is recovered;

[0057] (2) Use an extraction system composed of 10% neutral phosphine extractant TBP and kerosene as the organic phase to conduct a one-stage extraction and separation of vanadium and molybdenum in the vanadium-molybdenum leach solution, O / A=...

Embodiment 3

[0064] The spent vanadium-molybdenum-based SCR catalyst provided by a laboratory, V 2 o 5 Content 0.9%, MO 3 2.7%, TiO 2 It was 96.4%.

[0065] (1) Take the above spent catalyst, press m add :m metal =6 Add the additive KOH, then mix it evenly and put it in the muffle furnace for roasting to convert and remove impurities. The roasting temperature is 800°C and the roasting time is 4.5h; pure water is used as the leaching agent to extract vanadium and molybdenum from the solid phase product after roasting , the liquid-solid ratio is 0.05L / g, the leaching temperature is 25°C, the leaching time is 2.5h, the single-stage leaching rate of vanadium is 81%, and that of molybdenum is 70%. After filtering, the residue is recovered;

[0066] (2) Use an extraction system composed of 25% organic phosphine D2EHPA and kerosene as the organic phase to conduct a one-stage extraction and separation of vanadium and molybdenum in the vanadium-molybdenum leach solution, O / A=1:1, initial pH of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com