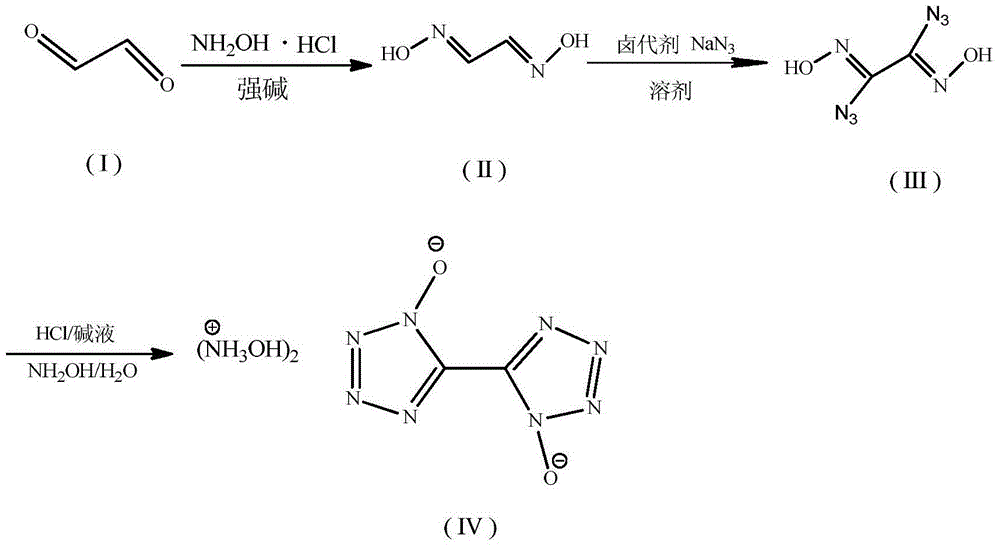

5, 5 '-bistetrazole-1, 1'-dioxo hydroxylammonium salt synthetic method

A technology of dioxanthamine salt and synthesis method, which is applied in the field of organic synthesis, can solve the problems of complex reaction process, low utilization rate of raw materials, insufficient optimization of TKX-50 synthesis process route, low yield, short reaction time, easy The effect of industrial scale-up production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of synthetic method of 5,5'-tetrazole-1,1'-dioxanolamine salt of the present invention, concrete steps are as follows:

[0022] 1) Dissolve 70g NaOH in 150mL water, add 139g hydroxylamine hydrochloride at 0°C, stir to dissolve, add 128g 40% glyoxal solution dropwise, react for 20min, remove the ice-water bath, and react overnight at room temperature. After filtering, washing with water and drying, 75.2 g of glyoxime was obtained with a yield of 86% and a melting point of 175-176°C.

[0023] 2) Add 50g of glyoxime obtained in step 1) into a container containing 500mL of DMF solvent, add 150g of N-chlorosuccinimide in batches at 0°C under constant stirring, remove the ice-water bath after adding , slowly rose to room temperature for 1h. Then put the container into ice water again, slowly add 74g of sodium azide at 0°C, and react for 3h to obtain 87.8g of diazideglyoxime. Yield 91%, melting point: 182-184°C.

[0024] 3) Put the diazideglyoxime solution obtained i...

Embodiment 2

[0026] A kind of synthetic method of 5,5'-tetrazole-1,1'-dioxanolamine salt of the present invention, concrete steps are as follows:

[0027] 1) Dissolve 80g of KOH in 150mL of water, add 139g of hydroxylamine hydrochloride at 0°C, stir to dissolve, add 128g of 40% glyoxal solution dropwise, react for 20min, remove the ice-water bath, and react overnight at room temperature. After filtering, washing with water and drying, 74.3 g of glyoxime was obtained with a yield of 85% and a melting point of 175-177°C.

[0028] 2) Add 50g of glyoxime obtained in step 1) into a container containing 500mL of DMF solvent, add 202g of N-bromosuccinimide in batches at 0°C under constant stirring, and remove the ice-water bath after adding , slowly rose to room temperature for 1h. Then put the container into ice water again, slowly add 74g of sodium azide at 0°C, and react for 3h to obtain 83.9g of diazideglyoxime. Yield 87%, melting point: 182-183°C.

[0029] 3) Put the diazideglyoxime solut...

Embodiment 3

[0031] A kind of synthetic method of 5,5'-tetrazole-1,1'-dioxanolamine salt of the present invention, concrete steps are as follows:

[0032] 1) 150g Ba(OH) 2 Dissolve in 150mL of water, add 139g of hydroxylamine hydrochloride at 0°C, stir to dissolve, add 152g of 40% glyoxal solution dropwise, react for 20min, remove the ice-water bath, and react overnight at room temperature. After filtering, washing with water and drying, 69.9 g of glyoxime was obtained with a yield of 80% and a melting point of 175-177°C.

[0033] 2) Add 50 g of glyoxime obtained in step 1) into a container containing 500 mL of DMF solvent, add 73.8 g of NaClO aqueous solution in batches at 0°C under constant stirring, remove the ice-water bath after the addition, and slowly rise to Reaction at room temperature for 1h. Then put the container into ice water again, slowly add 74g of sodium azide at 0°C, and react for 3h to obtain 64.2g of diazideglyoxime. Yield 65%, melting point: 182-185°C.

[0034] 3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| impact sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com