Nozzle for wire cutting machine

A wire-cutting machine tool and nozzle technology, applied in the field of wire-cutting machine tools, can solve the problem that electrode wire is prone to offset, and achieve the effects of reducing impact, reducing electrode wire offset, and increasing cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

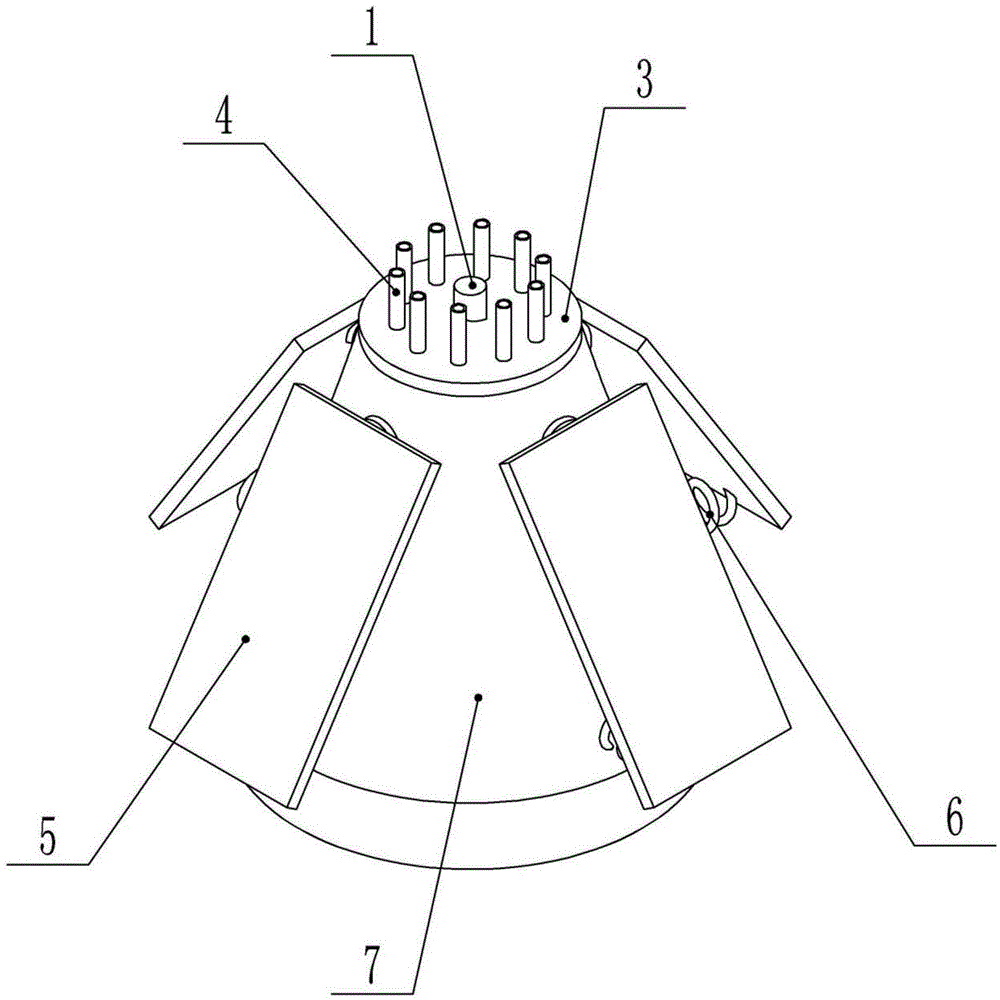

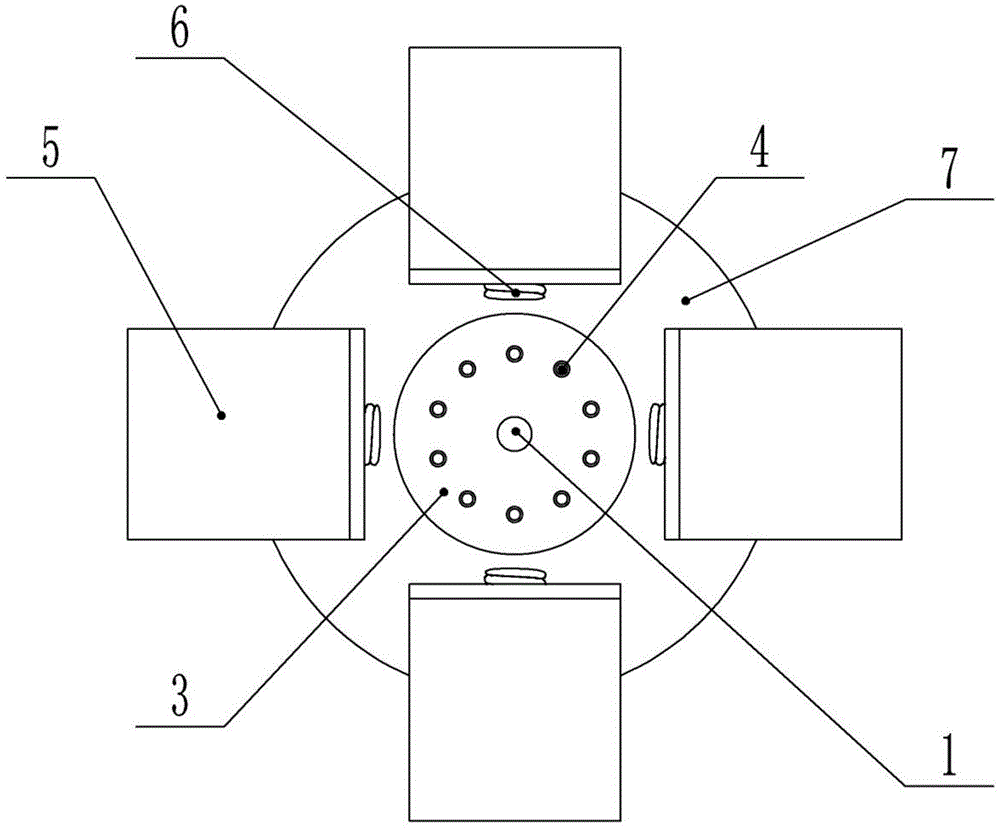

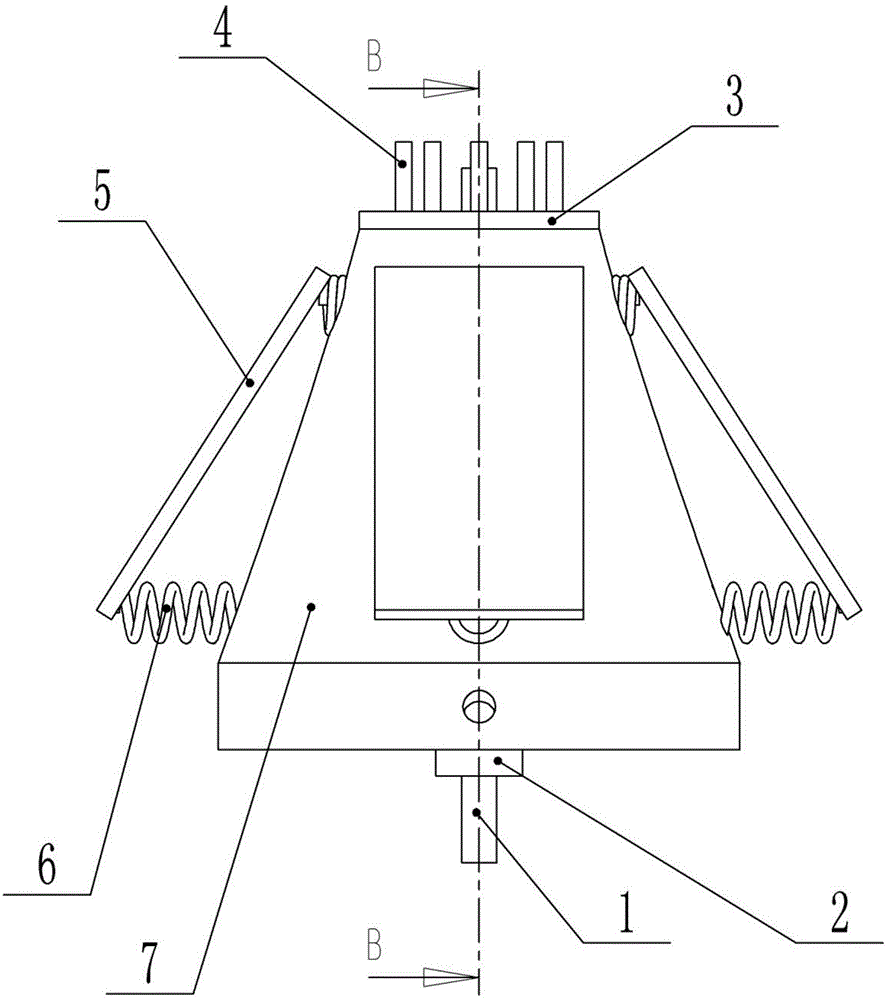

[0019] The reference signs in the description of the drawings are: electrode wire 1 , nozzle body 2 , guide plate 3 , guide tube 4 , buffer plate 5 , spring 6 , conical sleeve 7 , and fixing rod 8 .

[0020] This embodiment provides a nozzle for a wire cutting machine, such as figure 1 , figure 2 and image 3 As shown, it includes an electrode wire 1, a nozzle body 2, a guide plate 3, a guide tube 4 and a buffer device. The electrode wire 1 is covered with styrene-butadiene rubber, and is fixed in the electrode wire hole in the nozzle body 2 . The conical sleeve 7 is a hollow structure, which can accommodate the working fluid. The bottom surface of the conical sleeve 7 is provided with a through hole, and the wall of the through hole is provided with nitrile rubber. The nitrile rubber has a good sealing effect to ensure the bottom surface of the conical sleeve 7. of sealing. The top of the conical sleeve 7 is welded with a guide plate 3, and the center of the guide plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com