Medical titanium metal implant material and preparation method thereof

A technology of titanium metal and implants, which is applied in the field of medical titanium implant materials and its preparation, can solve the problems of long-term injection and the production of drug-resistant strains, and achieve good biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

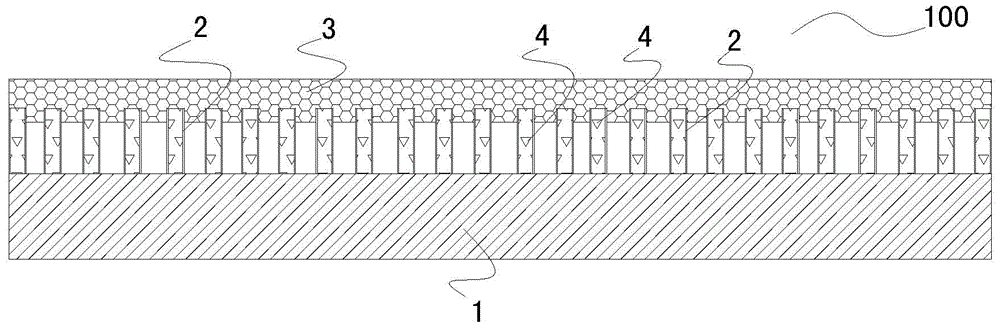

[0028] The second aspect of the present invention provides a method for preparing a medical titanium metal implant material 100, comprising the following steps:

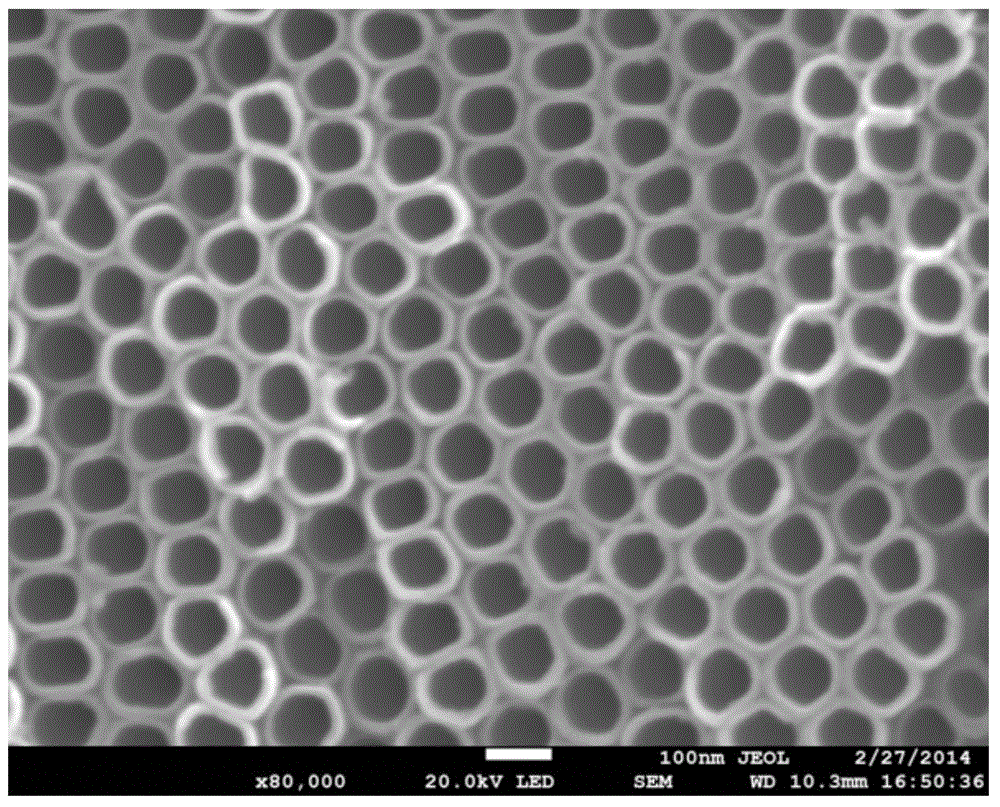

[0029] A. Use titanium metal 1 as the anode, use the solution containing F- as the electrolyte, react for 1-8h at a voltage of 20-40V, and a temperature of 30-60°C, wash and dry, and obtain a matrix row on the surface. Cloth of titanium dioxide nanotubes 2 of titanium metal 1;

[0030] B. loading anti-inflammatory and antibacterial drugs 4 in the titanium dioxide nanotubes 2 obtained in step A;

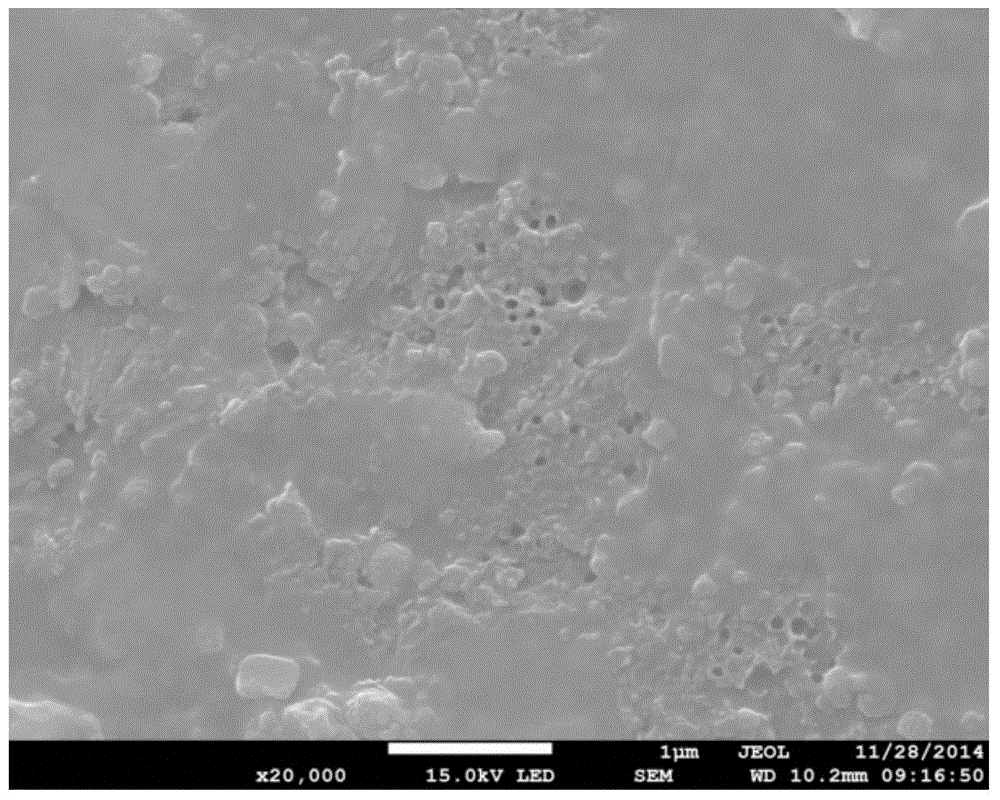

[0031] C. Coating the degradable polymer 3 solution on the end faces of the titanium dioxide nanotubes 2 arranged in a matrix, and drying to obtain the target product.

[0032] The degradable polymer 3 is one or a mixture of two or more of the following materials: glycolide / lactide copolymer, polyglycolic acid, polylactic acid, polycaprolactone and chitosan. Preferably, the mass volume ratio of the degradable polymer 3 sol...

Embodiment 1

[0041] step one,

[0042] For sample pretreatment, polish and polish the pure titanium metal sheet, place it in acetone and ultrasonically clean it for about 30 minutes, then ultrasonically clean it in deionized water for about 20 minutes, and set it aside.

[0043] step two,

[0044] The configuration of the etchant, the etchant consists of 10% HF and 40% HNO by volume 3 and 50%H 2 O mixed. spare.

[0045] Step three,

[0046] Configuration of electrolyte solution during anodic oxidation reaction, its composition is 0.3wt% NH 4 F, 3vol%H 2 O ethylene glycol solution, spare.

[0047] step four,

[0048] Configure a degradable polymer solution. The degradable polymer used in this case is lactide-glycolide copolymer (PLGA), the solvent used is chloroform, and the weight-to-volume concentration is 1%, for later use.

[0049] step five,

[0050] For sample encapsulation, copper wire is wrapped around the sample, and the back of the sample is coated with epoxy resin until...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com