A kind of low hygroscopic colloid bismuth pectin capsule and its preparation process

A technology of colloidal bismuth pectin and low hygroscopicity, which is applied in the direction of capsule delivery, organic active ingredients, and medical preparations of non-active ingredients, etc. It can solve the problems of reducing hygroscopicity, complicated preparation process, and difficult disintegration of capsule contents. , to achieve the effects of accelerated release speed, simple preparation process, and easy industrialized mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

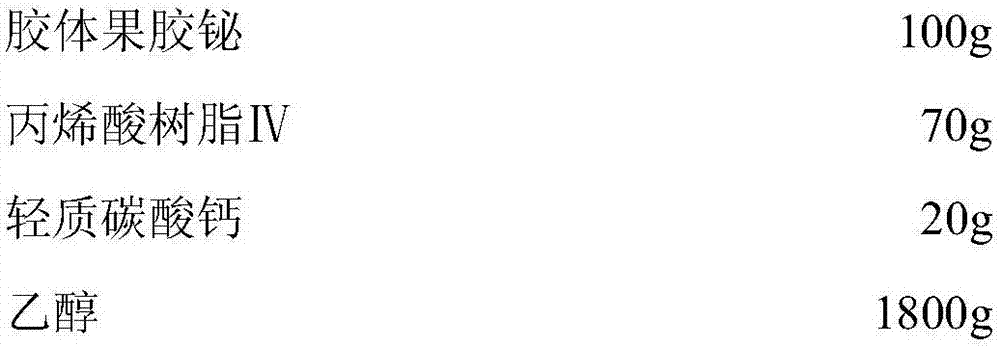

Embodiment 1

[0021]

[0022] Preparation Process:

[0023] (1) Dissolve acrylic resin IV in ethanol, add light calcium carbonate and stir evenly, process in a homogenizer, and set aside;

[0024] (2) Add colloidal bismuth pectin into the fluidized bed, spray the suspension coating in step (1) by the fluidized bed bottom spray coating method, the inlet air temperature is 35°C, the atomization pressure is 0.3-0.4MPa, Inlet pump speed 10-15rpm. After the coating is completed, put it in an oven at 50°C for aging treatment for 12 hours to obtain colloidal bismuth pectin-coated pellets;

[0025] (3) Sieve the pellets prepared in step (2) with 40-mesh and 80-mesh sieves respectively, and fill 3# capsule shells with 40-mesh-80-mesh pellets to obtain final product.

Embodiment 2

[0027]

[0028] Preparation Process:

[0029] (1) Dissolve acrylic resin IV in ethanol, add light calcium carbonate and stir evenly, process in a homogenizer, and set aside;

[0030] (2) Add colloidal bismuth pectin into the fluidized bed, spray the suspension coating in step (1) by the fluidized bed bottom spray coating method, the inlet air temperature is 35°C, the atomization pressure is 0.3-0.4MPa, Inlet pump speed 10-15rpm. After the coating is completed, put it in an oven at 50°C for aging treatment for 12 hours to obtain colloidal bismuth pectin-coated pellets;

[0031] (3) Sieve the pellets prepared in step (2) with 40-mesh and 80-mesh sieves respectively, and fill 2# capsule shells with 40-mesh-80-mesh pellets to obtain final product.

Embodiment 3

[0033]

[0034] Preparation Process:

[0035] (1) Dissolve acrylic resin IV in ethanol, add light calcium carbonate and stir evenly, process in a homogenizer, and set aside;

[0036] (2) Add colloidal bismuth pectin into the fluidized bed, spray the suspension coating in step (1) by the fluidized bed bottom spray coating method, the inlet air temperature is 35°C, the atomization pressure is 0.3-0.4MPa, Inlet pump speed 10-15rpm. After the coating is completed, put it in an oven at 50°C for aging treatment for 12 hours to obtain colloidal bismuth pectin-coated pellets;

[0037] (3) Sieve the pellets prepared in step (2) with 40-mesh and 80-mesh sieves respectively, and fill the 1# capsule shell with 40-mesh-80-mesh pellets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com