Preparation method of poly-3,4-ethylenedioxythiophene/graphite felt flexible electrode material

A technology of ethylenedioxythiophene and flexible electrodes, which is applied in the manufacture of hybrid/electric double layer capacitors, electrodes of hybrid capacitors, etc., can solve the problems of poor high temperature resistance, poor acid and alkali resistance, and low conductivity, and achieve high specific capacitance. , the effect of excellent mechanical properties, excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) In 80 mL deionized water, first add 2 g sodium lauryl sulfate, stir magnetically at room temperature for 15 min, then add 0.25 g 3,4-ethylenedioxythiophene, stir magnetically at room temperature for 45 min , and finally add 0.3 g Orange II, and magnetically stir at room temperature for 30 min to obtain a mixture of Orange II and 3,4-ethylenedioxythiophene.

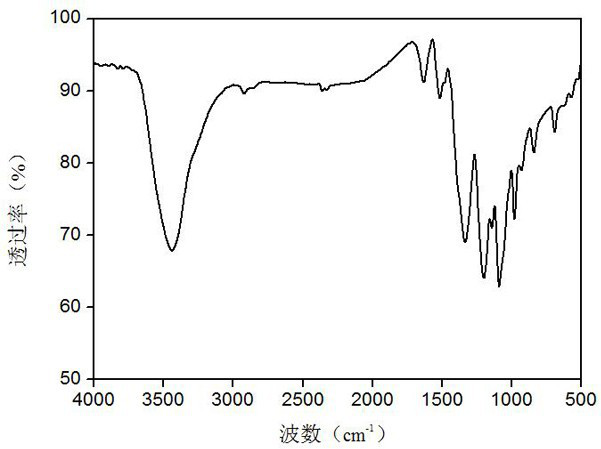

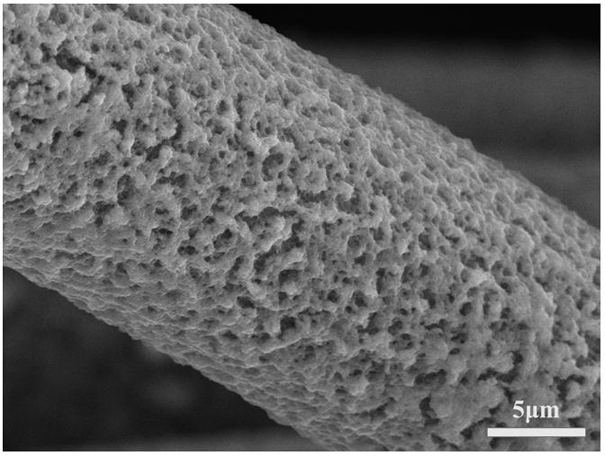

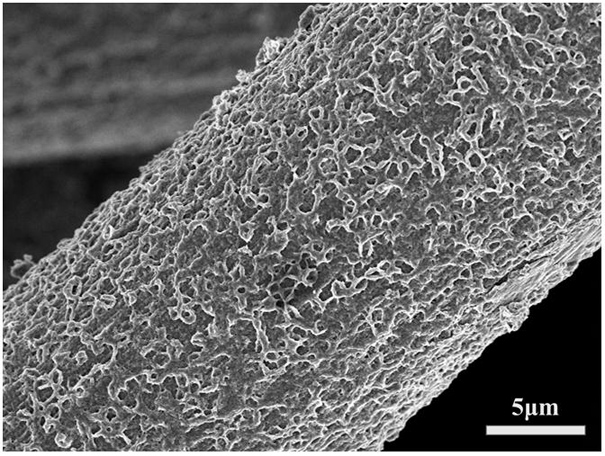

[0023] (2) Immerse the graphite felt sample into the mixed solution prepared in step (1), then add 20 mL ammonium persulfate hydrochloric acid solution into the mixed solution, and stir magnetically at room temperature for 14 h; the graphite felt sample After taking it out, first soak it in methanol for 8 hours, then soak it in 1 mol / L ammonia water for 36 hours, and finally soak it in 1 mol / L hydrochloric acid for 2 hours, wash it alternately with methanol and deionized water until the filtrate is colorless and at 60 °C After vacuum drying for 24 h, orange II doped poly-3,4-ethylenedioxythiophene / graphite felt ...

Embodiment 2

[0028] (1) In 50 mL deionized water, first add 1.5 g sodium dodecyl sulfate, stir magnetically at room temperature for 10 min, then add 0.2 g 3,4-ethylenedioxythiophene, and stir magnetically at room temperature for 30 min , and finally add 0.2 g Orange II, and magnetically stir at room temperature for 20 min to obtain a mixture of Orange II and 3,4-ethylenedioxythiophene.

[0029] (2) Immerse the graphite felt sample into the mixed solution prepared in step (1), then add 15 mL ammonium persulfate hydrochloric acid solution into the mixed solution, and stir magnetically at room temperature for 4 h; the graphite felt sample After taking it out, soak it in methanol for 5 hours, then soak it in 1 mol / L ammonia water for 24 hours, and finally soak it in 1 mol / L hydrochloric acid for 1 hour, and wash it alternately with methanol and deionized water until the filtrate is colorless and at 60 °C After vacuum drying for 24 h, orange II doped poly-3,4-ethylenedioxythiophene / graphite fel...

Embodiment 3

[0032] (1) In 100 mL deionized water, first add 2.5 g sodium dodecyl sulfate, stir magnetically at room temperature for 20 min, then add 0.3 g 3,4-ethylenedioxythiophene, stir magnetically at room temperature for 60 min , and finally add 0.35 g Orange II, and magnetically stir at room temperature for 40 min to obtain a mixture of Orange II and 3,4-ethylenedioxythiophene.

[0033](2) Immerse the graphite felt sample into the mixed solution prepared in step (1), then add 25 mL ammonium persulfate hydrochloric acid solution into the mixed solution, and stir magnetically at room temperature for 24 h; the graphite felt sample After taking it out, soak it in methanol for 10 h, then soak it in 1 mol / L ammonia water for 48 h, and finally soak it in 1 mol / L hydrochloric acid for 3 h, wash it alternately with methanol and deionized water until the filtrate is colorless and 60 °C After vacuum drying for 24 h, orange II doped poly-3,4-ethylenedioxythiophene / graphite felt composite materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com