Antibacterial organic silicone elastomer emulsion, preparation method and application thereof

A technology of silicone and body milk, which is applied in coatings, adhesive additives, paints containing biocide, etc., can solve the problems of inability to apply in areas with high mechanical performance requirements, complicated preparation methods, poor mechanical strength, etc., and achieve excellent Mechanical strength, easy operation, and the effect of good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

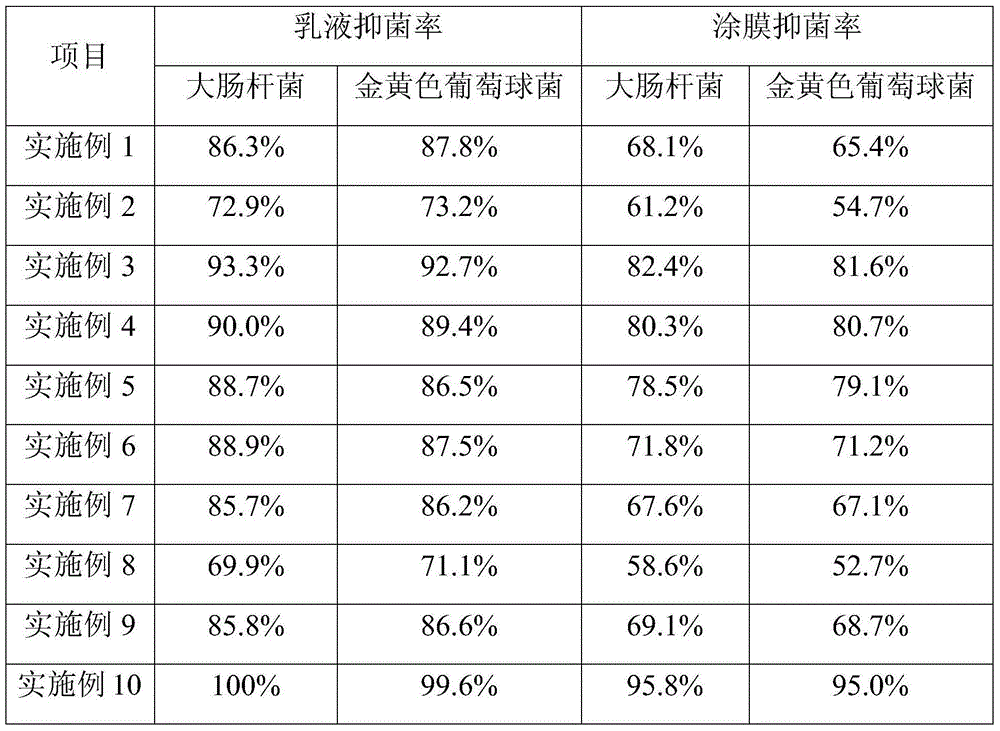

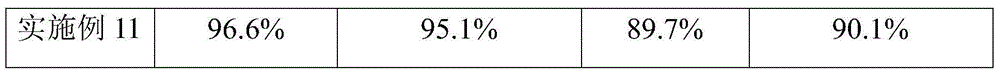

Examples

Embodiment 1

[0030] (1) 15g octadecyltrimethylammonium chloride, 20g polyether modified silicone oil (Dow Corning ) and 10g potassium hydroxide are dissolved in 625g water, add 10g 3-aminopropylmethyldimethoxysilane and 320g octamethylcyclotetrasiloxane (D4) and stir and mix to obtain a mixed material, and the mixed material is uniformly mixed at 30MPa Homogenize for 3 times under mass pressure, then pour into the reactor, heat to 70°C for 6 hours to obtain aminopolysiloxane emulsion;

[0031] (2) The amino polysiloxane emulsion temperature of step (1) is reduced to 50 ℃, add 10g nano-silica sol (colloid mean particle size is 40nm) and 20g glycidyl octadecyl dimethyl ammonium chloride, React for 5 hours under the condition of mechanical stirring to obtain the antibacterial silicone elastomer emulsion.

[0032] The glycidyl octadecyl dimethyl ammonium chloride of this embodiment refers to the literature (Wang Zunhai, Jiang Cuiyu, Song Linhua. Synthesis of epoxy propyl dimethyl dodecyl amm...

Embodiment 2

[0034] (1) Dissolve 50g of cetyltrimethylammonium chloride, 50g of isomeric tridecyl alcohol polyoxyethylene ether and 10g of potassium hydroxide in 440g of water, add 22.5g of 3-aminopropylmethyldimethoxy Silane and 427.5g of octamethylcyclotetrasiloxane (D4) were stirred and mixed uniformly to obtain a mixed material. The mixed material was homogenized for 4 times under a homogeneous pressure of 20MPa, then poured into the reactor, and heated to 60°C for 12 hours to obtain amino Silicone emulsion;

[0035] (2) Reduce the temperature of the aminopolysiloxane emulsion in step (1) to 45°C, add 30g of nano-silica sol (colloid average particle size is 20nm) and 40g of glycidyltrimethylammonium chloride, and react under microwave conditions After 1 hour, the antibacterial silicone elastomer emulsion was obtained.

Embodiment 3

[0037] (1) Dissolve 10g of cetyltrimethylammonium chloride, 10g of isomeric tridecyl alcohol polyoxyethylene ether and 20g of sodium hydroxide in 560g of water, add 32g of 3-aminopropylmethyldimethoxysilane Stir and mix with 368g of octamethylcyclotetrasiloxane (D4) to obtain a mixed material. The mixed material is homogenized for 5 times under a homogeneous pressure of 10MPa, then poured into the reactor, and heated to 80°C for 4 hours to obtain amino polysilicon oxane emulsion;

[0038] (2) Lower the temperature of the aminopolysiloxane emulsion in step (1) to 60°C, add 20g of Ag-loaded silica and 5g of epoxypropyltrimethylammonium chloride, and react for 1h under microwave conditions to obtain the antibacterial Silicone elastomer emulsion.

[0039] The Ag-loaded silica in this example was prepared by reference to the literature (Zhang Bin, Li Xiping, Bai Jinfeng. Preparation and antibacterial effect of antibacterial silica [J]. Chemical New Materials, 2004, 32(3): 23-25) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com