Method for preparing fluorocarbon alkyl imidazonline through fixed bed catalytic reaction

A fluorocarbon-based imidazoline and fixed-bed reactor technology, which is applied in organic chemistry and other fields, can solve problems such as greater influence on product purity, difficult separation of catalysts, solvent recovery environment, etc., and achieve high single-pot yield and short reaction time Short and three-waste pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

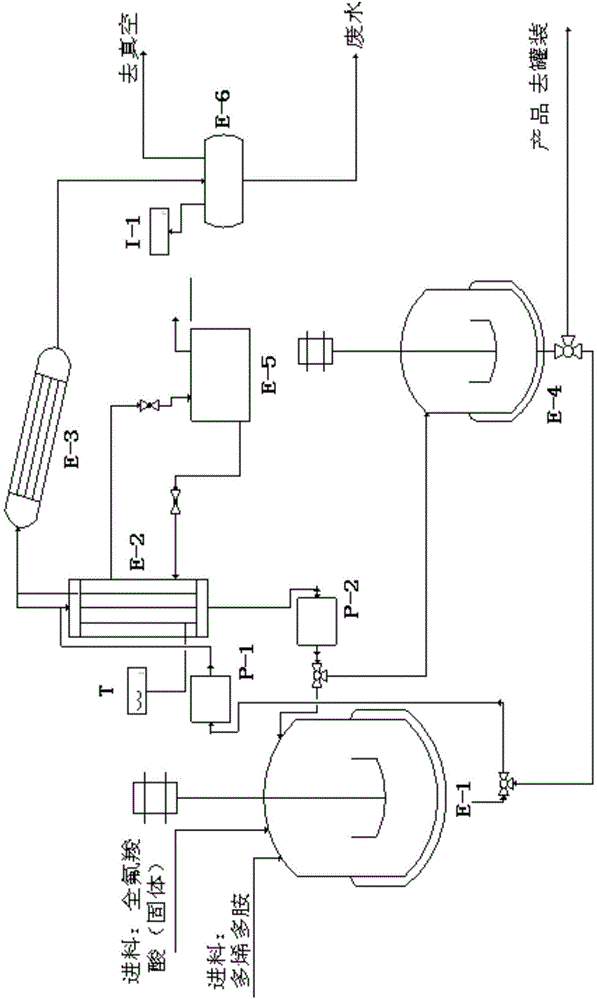

Image

Examples

Embodiment 1

[0013] In a 500ml stainless steel preheating kettle (E-1) equipped with a thermometer, agitator and pressure gauge, add 100g of diethylenetriamine, heat to 30°C, add 252g of perfluorovaleric acid and stir evenly, heat up to 130°C and keep warm For 30 minutes, use the fixed bed feed pump (P-1) to pump the preheated liquid into the fixed bed reactor (E-2) filled with 7g of catalyst. The catalyst is activated alumina supported phosphotungstic acid catalyst, The pump (P-2) pumps the effluent material from the fixed bed reactor (E-2) into the receiving tank (E-4), and the flow rate of the feed pump and the reflux pump (P-1, P-2) is 30ml / min, the fixed-bed reactor (E-2) is heated by a heat conduction oil tank (E-5), and the reaction temperature (T) is controlled at 150-160°C. The top of the fixed bed reactor (E-2) is equipped with a condenser (E-3) and a vacuum device (I-1), and the material is circulated to the fixed bed reactor (E-2) through the vacuum device (I-1). 0~-0.03MPa v...

Embodiment 2

[0019] In a 500ml stainless steel preheating kettle (E-1) equipped with a thermometer, agitator and pressure gauge, add 100g of diethylenetriamine, heat to 30°C, add 299g of perfluorohexanoic acid and stir evenly, heat up to 132°C and keep warm For 30 minutes, use the fixed bed feed pump (P-1) to pump the preheated liquid into the fixed bed reactor (E-2) filled with 8g of catalyst. The catalyst is activated alumina supported phosphotungstic acid catalyst, The pump (P-2) pumps the effluent material from the fixed bed reactor (E-2) into the receiving tank (E-4), and the flow rate of the feed pump and the reflux pump (P-1, P-2) is 30ml / min, the fixed bed reactor (E-2) is heated by heat conduction oil (E-5), and the reaction temperature (T) is controlled at 150-160°C. The top of the fixed bed reactor (E-2) is equipped with a condenser (E-3) and a vacuum device (I-1), and the material is circulated to the fixed bed reactor (E-2) through the vacuum device (I-1). 0~-0.03MPa vacuum ...

Embodiment 3

[0021] In a 500ml stainless steel preheating kettle (E-1) equipped with a thermometer, agitator and pressure gauge, add 100g of diethylenetriamine, heat to 34°C, add 349g of perfluoroheptanoic acid and stir evenly, heat up to 130°C and keep warm For 30 minutes, use the fixed bed feed pump (P-1) to pump the preheated liquid into the fixed bed reactor (E-2) filled with 9g of catalyst. The catalyst is activated alumina supported phosphotungstic acid catalyst, The pump (P-2) pumps the effluent material from the fixed bed reactor (E-2) into the receiving tank (E-4), and the flow rate of the feed pump and the reflux pump (P-1, P-2) is 30ml / min, the fixed bed reactor (E-2) is heated by heat conduction oil (E-5), and the reaction temperature (T) is controlled at 150-160°C. The top of the fixed bed reactor (E-2) is equipped with a condenser (E-3) and a vacuum device (I-1), and the material is circulated to the fixed bed reactor (E-2) through the vacuum device (I-1). 0~-0.03MPa vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com