Method for producing L-citrulline with high efficiency

A citrulline and high-efficiency technology, applied in the field of bioengineering, can solve problems such as insufficient conversion rate, low production intensity, and long conversion time, and achieve the effects of increasing reaction speed, reducing production cycle, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Construction of genetically engineered bacteria containing arginine deiminase

[0041] Construct genetically engineered bacteria containing arginine deiminase as follows:

[0042] (1) Use primers 1 whose sequences are respectively shown in SEQ ID NO.3 and SEQ ID NO.4 by means of molecular biology:

[0043] 5'-CATGCCATGGCAATGAACAATGGAATTAATGTTAACTCAG-3' and Primer 2:

[0044]5'-CCGCTCGAGTTACAAATCTTCACGGCAAAGTGG-3'Arginine deiminase gene (amino acid sequence shown in SEQ ID NO.1, nucleotide sequence shown in SEQ ID NO.2) from Lactococcus lactis was subjected to PCR amplification : Add LAtaq enzyme to the system, pre-denature at 94°C for 3min, denature at 94°C for 30s, anneal at 55°C for 30s, extend at 72°C for 1.5min, 30 cycles, and finally extend at 72°C for 10min;

[0045] (2) Digest the target gene and expression vector pET28a with restriction enzymes NcoI and xhoI at 37°C for 2 hours;

[0046] (3) Use T4 ligase to ligate the target gene and plasmid pET28...

Embodiment 2

[0049] Embodiment 2: Induced expression of genetically engineered bacteria

[0050] Induce genetically engineered bacteria to express arginine deiminase as follows:

[0051] (1) Insert the genetically engineered bacteria of construction into LB slant medium and cultivate for 12h;

[0052] (2) Put a ring of slanted seeds into the LB medium and cultivate for 6 hours;

[0053] (3) Insert the seed solution into the LB fermentation medium and cultivate to OD 600 0.6, adding IPTG with a final concentration of 0.4mmol / L for induction, 6h later, the cells were collected, and the cells were washed with sterile normal saline.

Embodiment 3

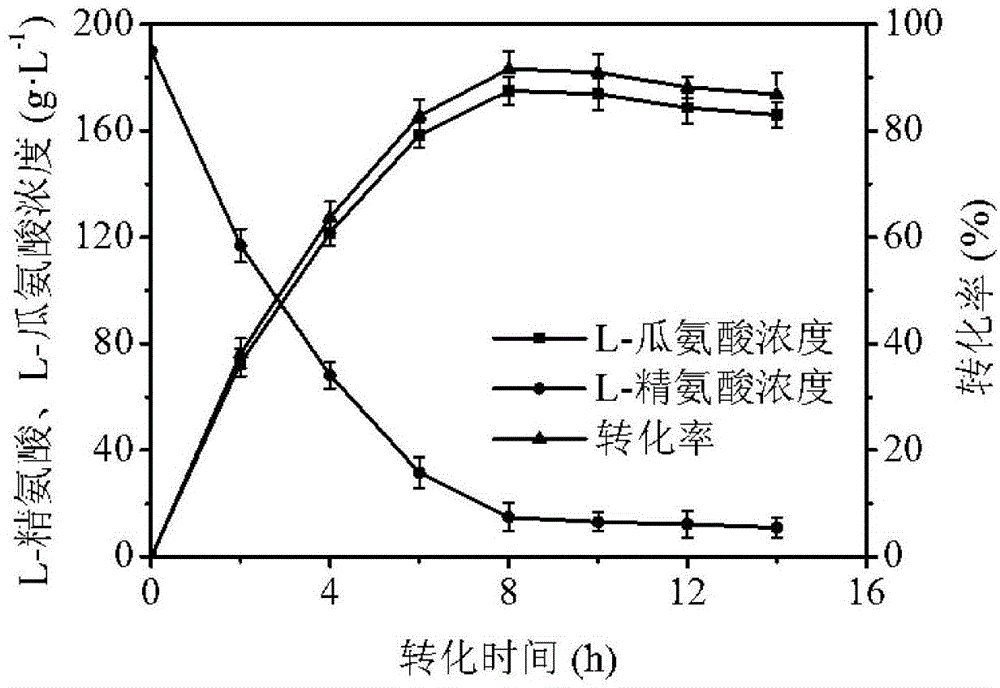

[0054] Embodiment 3: Transform L-arginine to produce L-citrulline

[0055] Cultivate the genetically engineered bacterium constructed in Example 1, and induce it to express arginine deiminase, then collect the genetically engineered bacterium, and wash the thalline twice with sterile physiological saline;

[0056] Take 7g (wet weight) of the bacteria, crush it and put it into 1L of transformation solution for transformation. The transformation conditions are: the concentration of substrate arginine is 200g, the transformation temperature is 50°C, pH 7.2, and the transformation time is 8h;

[0057] Take an appropriate amount of transformation liquid, and use high performance liquid chromatography to determine the content of L-citrulline in the transformation liquid. The results show that the output of L-citrulline can reach 120.9g / L, and the production intensity can reach 15.1g·(L·h) -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com