A kind of matte type epoxy resin encapsulation adhesive for outdoor LED encapsulation and preparation method thereof

A technology of LED encapsulation and epoxy resin, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of high brightness of LED light, poor heat-resistant yellowing performance, high stress of epoxy compound, etc. The effect of strong operability, stable performance and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

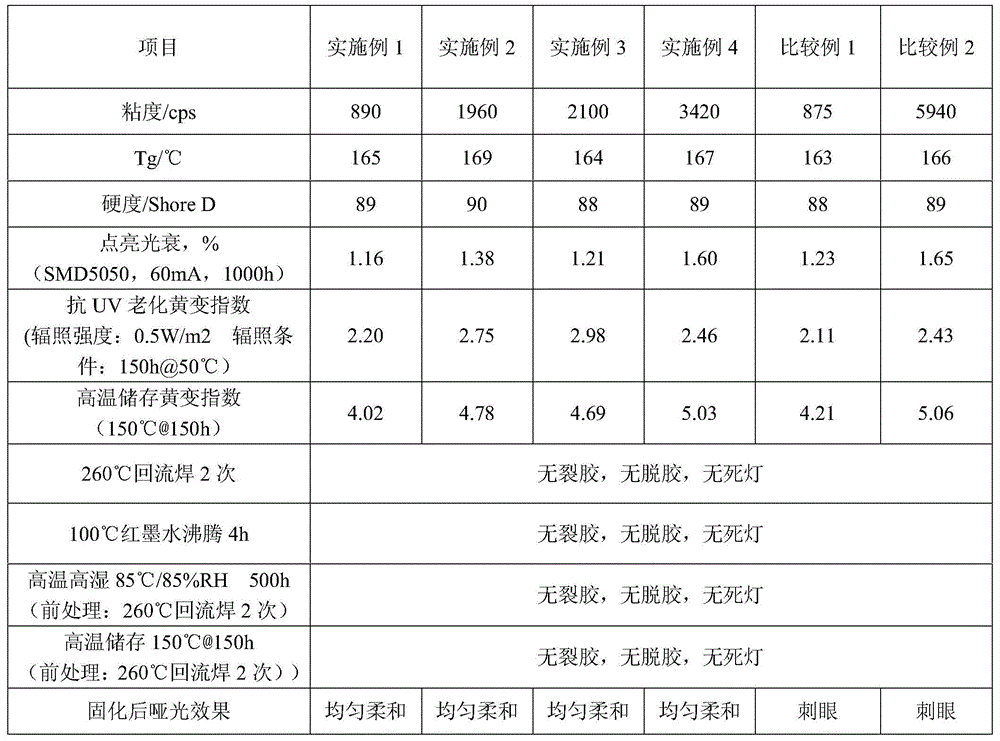

Examples

Embodiment 1

[0025] First, prepare the matte powder according to the following steps: (1') First, combine the fumed silica powder (the average particle size of fumed silica powder is 5μm) with spherical methyl solid silicone resin powder (spherical methyl solid The average particle size of the silicone resin powder is 9μm.) Mix uniformly according to the weight ratio of 3:2 to obtain a mixed powder; (2') Dissolve γ-glycidoxypropyltrimethoxysilane in ethanol to prepare a weight percentage concentration Is a 10% solution, then add acetic acid to the solution and adjust the pH to 4.5 (acetic acid can play a catalytic role); (3') add the mixed powder obtained in step (1') to the solution obtained in step (2') And carry out high-speed dispersion to obtain a mixture material; (4') the mixture material obtained in step (3') is filtered to remove the filtrate, and the solid matter obtained by the filtration is dried to obtain a matte powder.

[0026] In the above step (3'), the weight ratio of the mi...

Embodiment 2

[0033] First, prepare the matte powder according to the following steps: (1') First, combine the fumed silica powder (the average particle size of fumed silica powder is 8μm) with spherical methyl solid silicone resin powder (spherical methyl solid The average particle size of the silicone resin powder is 10μm.) Mix uniformly according to the weight ratio of 1:0.5 to obtain a mixed powder; (2') Dissolve γ-glycidoxypropyltrimethoxysilane in ethanol to prepare a weight percentage concentration Is an 8% solution, then add oxalic acid to the solution and adjust the PH value to 4 (oxalic acid can play a catalytic role); (3') add the mixed powder obtained in step (1') to step (2') (4') The mixture obtained in step (3') is filtered to remove the filtrate, and the solid matter obtained by the filtration is dried to obtain a matte powder.

[0034] In the above step (3'), the weight ratio of the mixed powder obtained in step (1') to the solution obtained in step (2') is 2:1.

[0035] Then, ...

Embodiment 3

[0041] First, prepare the matte powder according to the following steps: (1') First, combine the fumed silica powder (the average particle size of fumed silica powder is 5μm) with spherical methyl solid silicone resin powder (spherical methyl solid The average particle size of the silicone resin powder is 7μm.) Mix uniformly according to the weight ratio of 1:2 to obtain a mixed powder; (2') Dissolve γ-glycidoxypropyltrimethoxysilane in ethanol to prepare a weight percentage concentration Is a 14% solution, then add acetic acid to the solution and adjust the pH to 5 (acetic acid can play a catalytic role); (3') add the mixed powder obtained in step (1') to the solution obtained in step (2') And carry out high-speed dispersion to obtain a mixture material; (4') the mixture material obtained in step (3') is filtered to remove the filtrate, and the solid matter obtained by the filtration is dried to obtain a matte powder.

[0042] In the above step (3'), the weight ratio of the mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com