A kind of salt particle used in the micro-surface of asphalt pavement and its preparation method

A kind of technology of asphalt pavement and salt compound, which is applied in the direction of building structure, building components, building insulation materials, etc., can solve the problems of difficult precipitation, loss, and decline in the anti-skid performance of the road surface, so as to ensure the compressive strength and surface hardness, good Effect of plasticity and viscosity, good envelope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

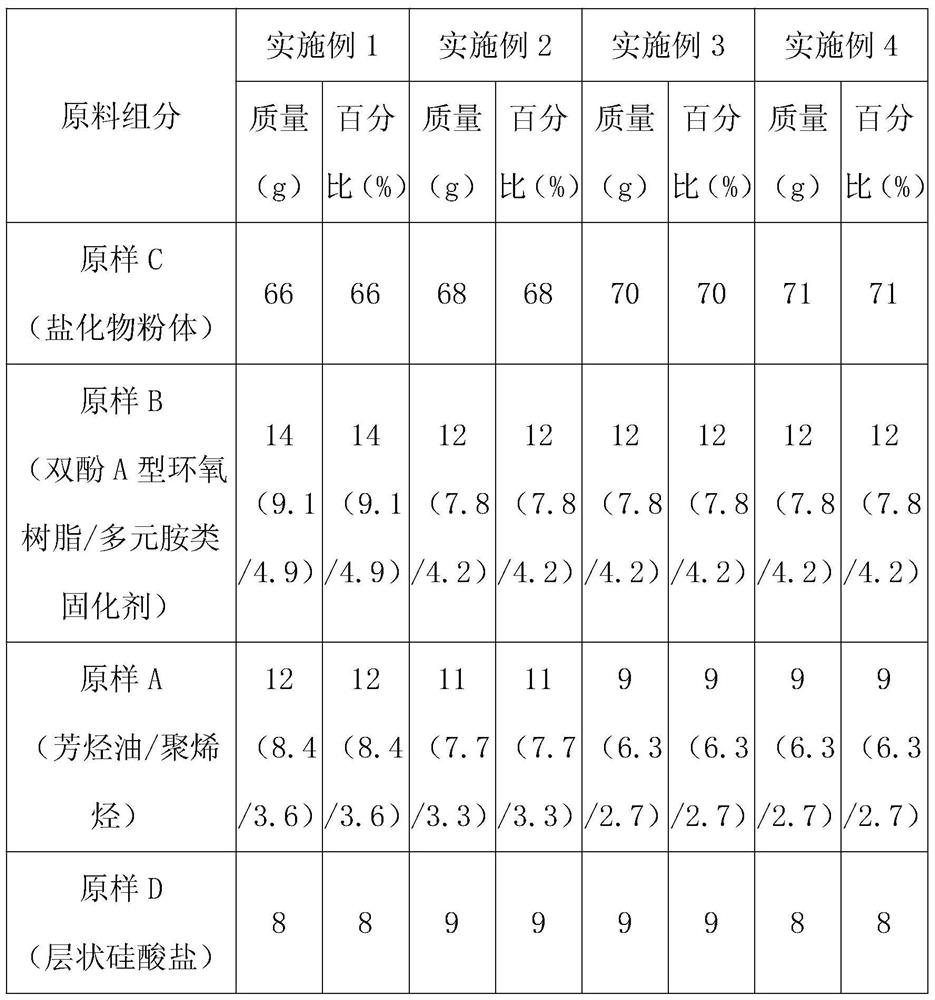

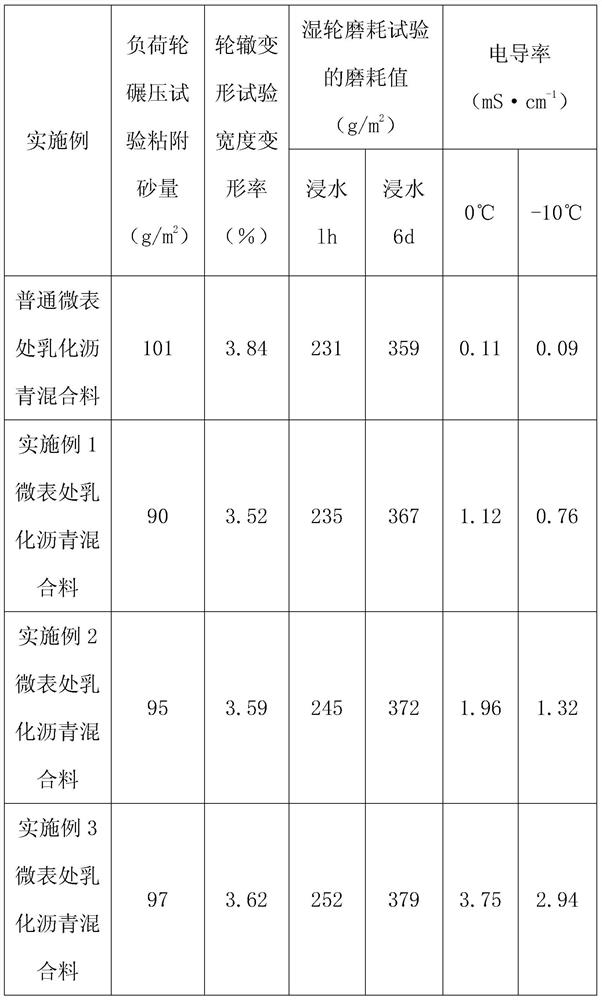

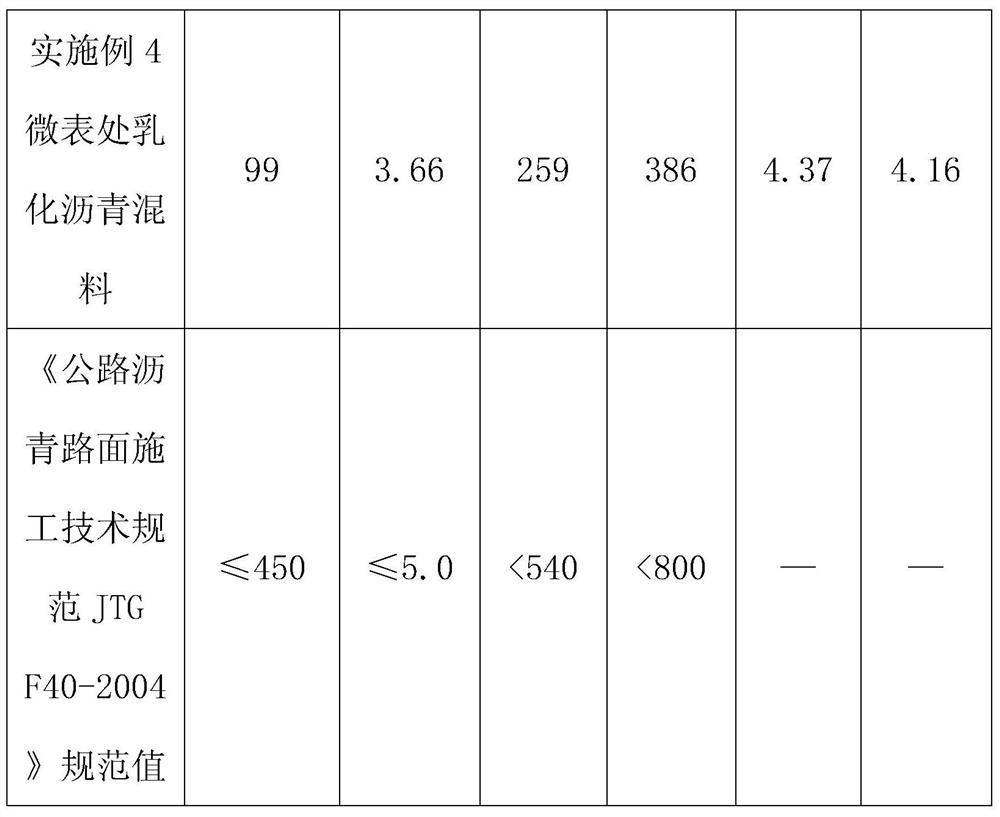

[0032] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the examples.

[0033] (1) the present invention prepares the method step of the salt particle at asphalt pavement microsurface place as follows:

[0034] Step 1: Add 15g of low-density polyethylene, 15g of polypropylene and 70g of aromatic oil in sequence to a 500ml glass cup, stir and mix well to obtain mixture A; place mixture A on an adjustable temperature electric furnace, and control the temperature at 90-120 Between ℃, marked as original A, for future use.

[0035] Step 2: In a 500ml glass cup, add 65g of bisphenol A epoxy resin and 35g of polyamine curing agent in turn, stir and mix well to obtain mixture B; place mixture B on an adjustable temperature electric furnace, and control the temperature at 48 Between ℃~52℃, marked as original B, for future use....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com