Preparation method for anti-icing silicone rubber composite material surface

A composite material and silicone rubber technology, which is applied in the field of anti-icing surface preparation, can solve problems such as poor durability, time-consuming deicing, and poor mechanical stability of super-hydrophobic surfaces, and achieve the effect of reducing deliquescence and freezing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

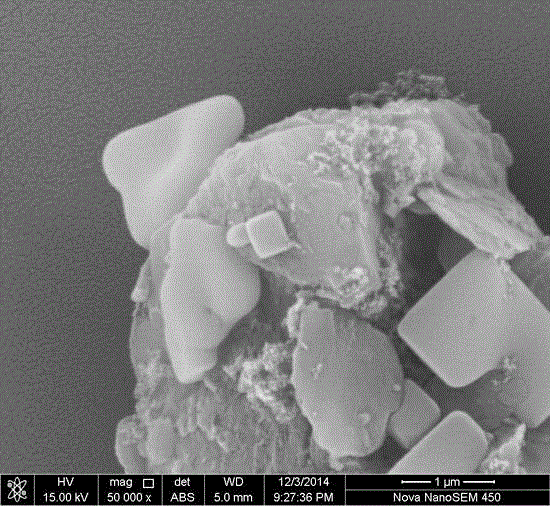

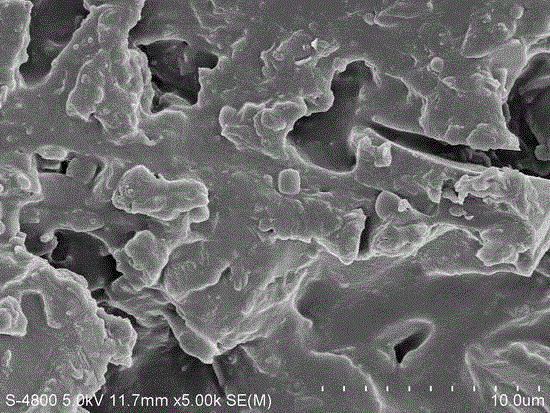

[0022] Preparation of modified potassium chloride particles: Dissolve 300 g of commercially available analytically pure potassium chloride in 500 ML deionized water at 60-80 °C, filter while hot to obtain a saturated potassium chloride aqueous solution, and use a volumetric flask to volume , keep warm for later use; under mechanical stirring, disperse 50 g of commercially available diatomite in 1000 ML of acetone through a 200-mesh stainless steel sampling sieve, then add 5 g of emulsifier OP-10, and keep stirring for 30 min; Adjust the pH value of the saturated solution to 1 with concentrated hydrochloric acid, and then add it to the above-mentioned acetone dispersion in 5 times within 10 minutes, and continue to stir for 2 h after the addition to obtain a mixed solution; add 10 g of nano-silica powder to Into the mixed solution obtained in the third step, continue mechanical stirring for 30 min, and then filter under reduced pressure, and dry the obtained filter cake at 150°C...

Embodiment 2

[0027] Preparation of modified potassium chloride particles: Dissolve 300 g of commercially available analytically pure potassium chloride in 500 ML deionized water at 60-80 °C, filter while hot to obtain a saturated potassium chloride aqueous solution, and use a volumetric flask to volume , keep warm for later use; under mechanical stirring, disperse 50 g of commercially available diatomite in 1000 ML of acetone through a 200-mesh stainless steel sampling sieve, then add 5 g of emulsifier OP-10, and keep stirring for 30 min; Adjust the pH value of the saturated solution to 1 with concentrated hydrochloric acid, and then add it to the above-mentioned acetone dispersion in 5 times within 10 minutes, and continue to stir for 2 h after the addition to obtain a mixed solution; add 10 g of nano-silica powder to Into the mixed solution obtained in the third step, continue mechanical stirring for 30 min, and then filter under reduced pressure, and dry the obtained filter cake at 150°C...

Embodiment 3

[0032]Preparation of modified potassium chloride particles: Dissolve 300 g of commercially available analytically pure potassium chloride in 500 ML deionized water at 60-80 °C, filter while hot to obtain a saturated potassium chloride aqueous solution, and use a volumetric flask to volume , keep warm for later use; under mechanical stirring, disperse 50 g of commercially available diatomite in 1000 ML of acetone through a 200-mesh stainless steel sampling sieve, then add 5 g of emulsifier OP-10, and keep stirring for 30 min; Adjust the pH value of the saturated solution to 1 with concentrated hydrochloric acid, and then add it to the above-mentioned acetone dispersion in 5 times within 10 minutes, and continue to stir for 2 h after the addition to obtain a mixed solution; add 10 g of nano-silica powder to Into the mixed solution obtained in the third step, continue mechanical stirring for 30 min, and then filter under reduced pressure, and dry the obtained filter cake at 150°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com