Energy-saving and consumption-reduction stable operation device and method for enhancing aerobic granule sludge

An aerobic granular sludge, stable operation technology, applied in chemical instruments and methods, water/sludge/sewage treatment, energy wastewater treatment, etc., can solve high energy consumption, restrict industrial applications, affect the stability of particle structure, etc. problems, achieve the effect of compact particle structure, reduce energy consumption, and overcome high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

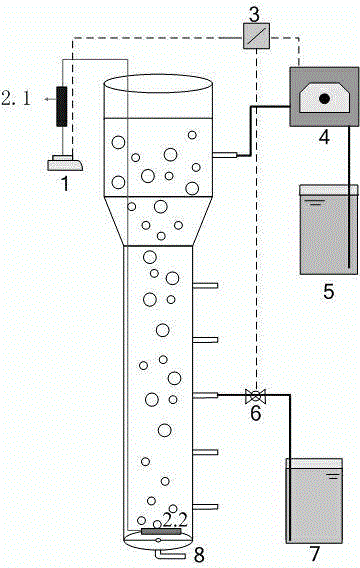

[0029] In this case, the aerobic granular sludge process for treating urban sewage uses a sequencing batch reactor (SBR) with an effective volume of 3.5 L, such as figure 1 As shown: the main body of the reactor is a cylindrical plexiglass cylinder with a height of 55 cm and an inner diameter of 9 cm. There are multiple sludge discharge sampling ports 8 from top to bottom from the side to the bottom. The water inlet is located at the upper part of the reactor, and a submersible pump 4 pumps the urban sewage in the water inlet barrel 5 into the main body of the reactor. The aeration device is composed of an air pump 1 connected to a rotameter 2.1 and a porous aeration head 2.2, and the porous aeration head is placed at the bottom of the reactor cylinder. The water outlet unit is pumped by a peristaltic pump 6 from the middle and lower part of the reactor to the water outlet bucket 7, and a mud discharge sampling port 8 located in the middle of the reactor main body is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com