Preparation method of shape-controllable nano CuO (copper oxide) powder

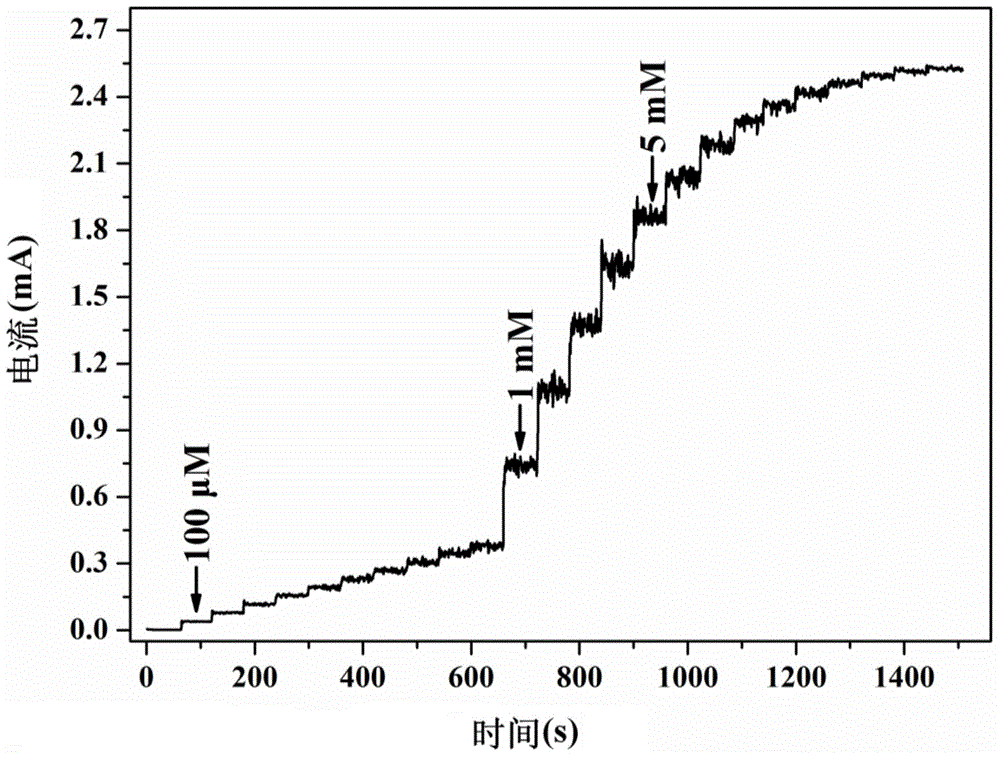

A nano-copper oxide and powder technology is applied in the field of materials to achieve the effects of good application prospects, good sensing and energy storage characteristics, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Add 28.8mg of Cu with an average particle size of about 40nm 2 O powder was added to 24 mL deionized water (Cu 2 The mass ratio of O powder to deionized water is 1:833), using a magnetic stirrer to stir for 5min at a speed of 400rpm / min at 25°C to obtain a suspension;

[0027] 2) 1 mL of 1% hydrogen peroxide (H 2 o 2 ) solution was added to the suspension, stirred and reacted at 25°C at a speed of 400rpm / min for 20h to obtain the primary product of CuO; the volume ratio of the added hydrogen peroxide solution to the water in the suspension was 1:24.

[0028] 3) The CuO primary product was centrifuged and washed 5 times with deionized water and absolute ethanol repeatedly, each time for 2 minutes, the centrifugal speed was 8000rpm / min, and finally placed in a vacuum drying oven and dried at a temperature of 50°C and a pressure of 120Pa After 12 hours, nano-copper oxide powder was obtained.

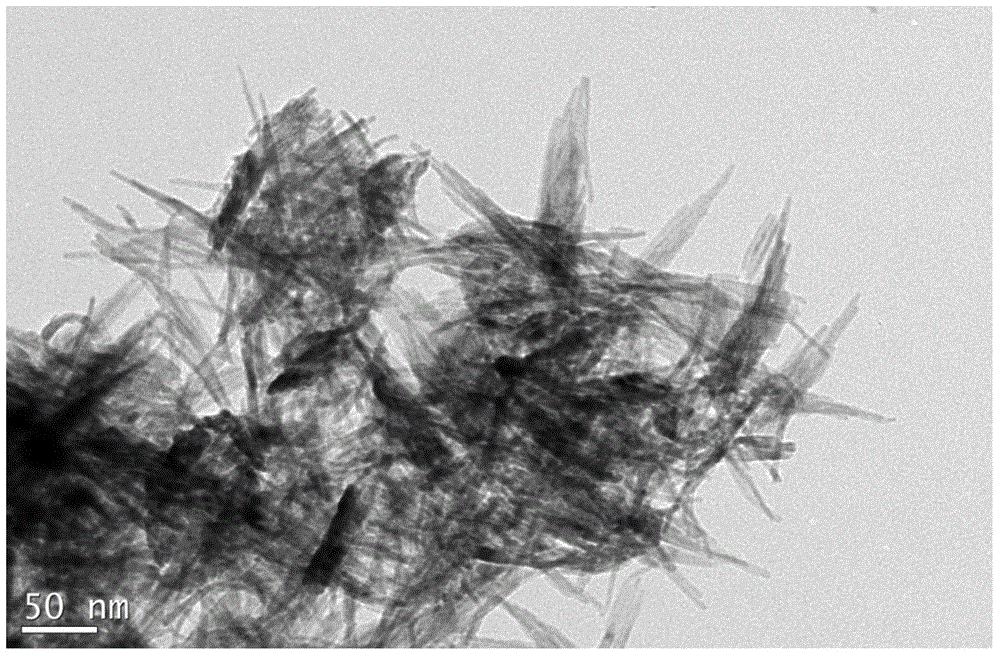

[0029] The morphology of the nanometer copper oxide powder that embodimen...

Embodiment 2

[0031] 1) Add 85mg of Cu with an average particle size of about 100nm 2 O powder was added to 60mL deionized water (Cu 2 O powder and deionized water mass ratio is 1:706), utilize magnetic stirrer to stir 5min with the speed of 400rpm / min at 25 ℃, obtain suspension;

[0032] 2) 40mL mass fraction of 5% hydrogen peroxide (H 2 o 2 ) solution was added to the suspension, stirred and reacted at 25°C at a speed of 400rpm / min for 25h to obtain the CuO primary product; the volume ratio of the added hydrogen peroxide solution to the water in the suspension was 1:1.5.

[0033] 3) The CuO primary product was centrifuged and washed 5 times with deionized water and absolute ethanol repeatedly, each time for 2 minutes, the centrifugal speed was 8000rpm / min, and finally placed in a vacuum drying oven and dried at a temperature of 50°C and a pressure of 120Pa After 12 hours, nano-copper oxide powder was obtained.

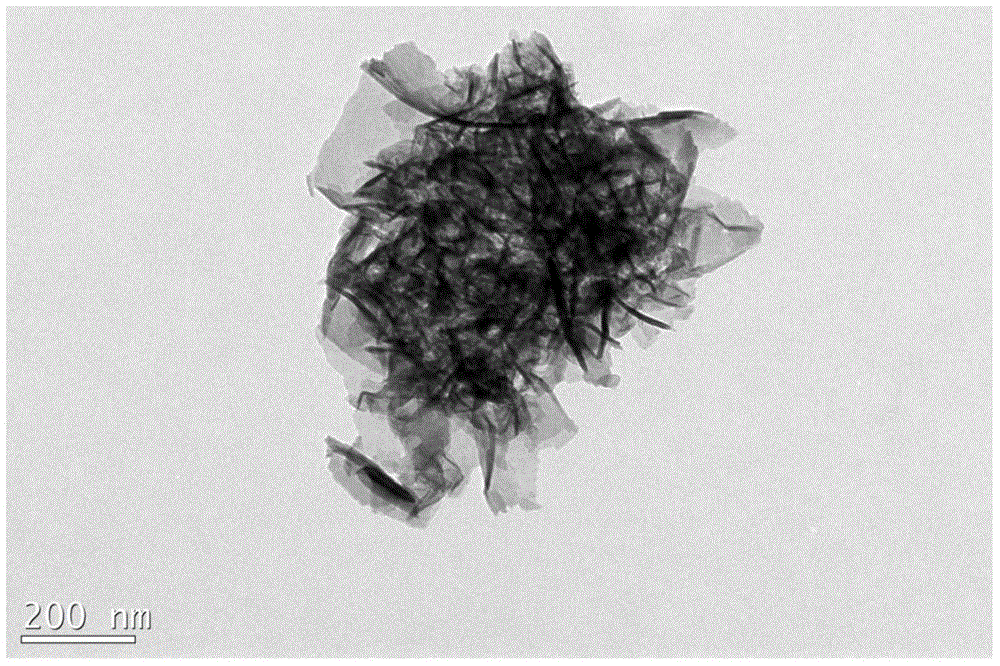

[0034] The appearance of the nano-copper oxide powder that embodiment 2 o...

Embodiment 3

[0037] 1) Add 28.8 mg of Cu with an average particle size of about 80 nm 2 O powder was added to 24 mL deionized water (Cu 2 The mass ratio of O powder to deionized water is 1:833), using a magnetic stirrer to stir for 5min at a speed of 400rpm / min at 25°C to obtain a suspension;

[0038] 2) 1 mL of 5% hydrogen peroxide (H 2 o 2 ) solution was added to the suspension, stirred and reacted at 25°C at a speed of 400rpm / min for 28h to obtain the primary product of CuO; the volume ratio of the added hydrogen peroxide solution to the water in the suspension was 1:24.

[0039] 3) The CuO primary product was centrifuged and washed 5 times with deionized water and absolute ethanol repeatedly, each time for 3 minutes, and the centrifugal speed was 8000rpm / min, and finally placed in a vacuum drying oven and dried at a temperature of 50°C and a pressure of 120Pa After 12 hours, nano-copper oxide powder was obtained.

[0040] The appearance of the nano-copper oxide powder that embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com