A method for strengthening the species of supersaturated sodium aluminate solution

A sodium aluminate and solution technology, applied in the field of aluminum metallurgy, can solve the problems of difficult separation of methanol and sodium aluminate solution, influence of alumina production, difficulty in production organization, etc. The effect of organizing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

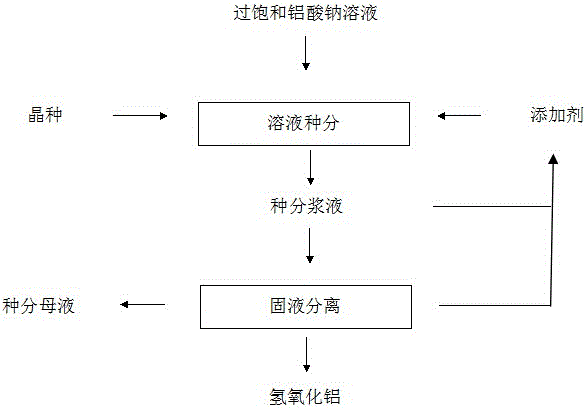

[0030] A method for strengthening the species of supersaturated sodium aluminate solution of the present invention, such as figure 1 As shown, using supersaturated sodium aluminate solution as raw material (such as the sodium aluminate solution obtained after processing boehmite or boehmite by Bayer method), control the solution concentration Na 2 O (caustic)=162g / L, Al 2 o 3 =183.2g / L. Take 50ml supersaturated sodium aluminate solution, add 50ml sodium bicarbonate suspension (NaHCO 3 45g / L), reacted under strong stirring conditions at 30°C for 60min, precipitated aluminum hydroxide, and obtained active aluminum hydroxide seed crystal slurry. Add 950ml of supersaturated sodium aluminate solution to the seeding tank, add active aluminum hydroxide seed slurry under stirring conditions, and add 20ml of 28% ammonia water, control the initial temperature of seeding at 55°C, start seeding, control The final temperature of seed separation is 45°C, and after 40 hours of seed sepa...

Embodiment 2

[0033] Take supersaturated sodium aluminate solution 1000mL, control solution concentration Na 2 O=165g / L,Al 2 o 3 =183.2g / L, Na 2 o c (sodium carbonate) = 13.5g / L. Add 300g / L aluminum hydroxide as a seed crystal, then add 10mL of 28% ammonia water, control the temperature of the seed separation at 60°C, lower the temperature to decompose, the final temperature of the seed separation is 45°C, decompose for 45 hours, filter the seed separation slurry, and the decomposition rate is 64% . In the process of seed separation and filtration, ammonia gas is recovered with water to obtain ammonia water for reuse.

Embodiment 3

[0035] A method for intensifying seed classification of supersaturated sodium aluminate solution of the present invention, using supersaturated sodium aluminate solution as raw material (such as sodium aluminate solution for seed classification obtained by processing gibbsite by Bayer method), and controlling the concentration of the solution Na 2 O=135g / L,Al 2 o 3 =153.7g / L. Take 30ml of supersaturated sodium aluminate solution, add 10ml of 30% hydrogen peroxide, and react under strong stirring at 40°C for 60 minutes to precipitate aluminum hydroxide and obtain active aluminum hydroxide seed slurry. Add 950ml of supersaturated sodium aluminate solution into the seeding tank, control the initial temperature of seeding at 50°C; add active aluminum hydroxide seed slurry under stirring conditions, and feed ammonia gas to maintain the pressure at 0.1kg / cm 2 , Start seeding, control the end temperature of seeding at 45°C, after 35 hours of seeding, the decomposition rate is 76%....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com