Preparation method of a high-efficiency catering oil fume treatment module

A technology for oil fume treatment and catering, which is applied in the direction of oil fume removal, separation methods, chemical instruments and methods, etc. It can solve the problem that it is not suitable to install the front end of the fan blade of the range hood and the middle of the flue gas duct, and the porous cordierite ceramic has a low oil absorption value. , limited oil fume absorption capacity, etc., to achieve the effect of adjustable size, good removal effect, and improved absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

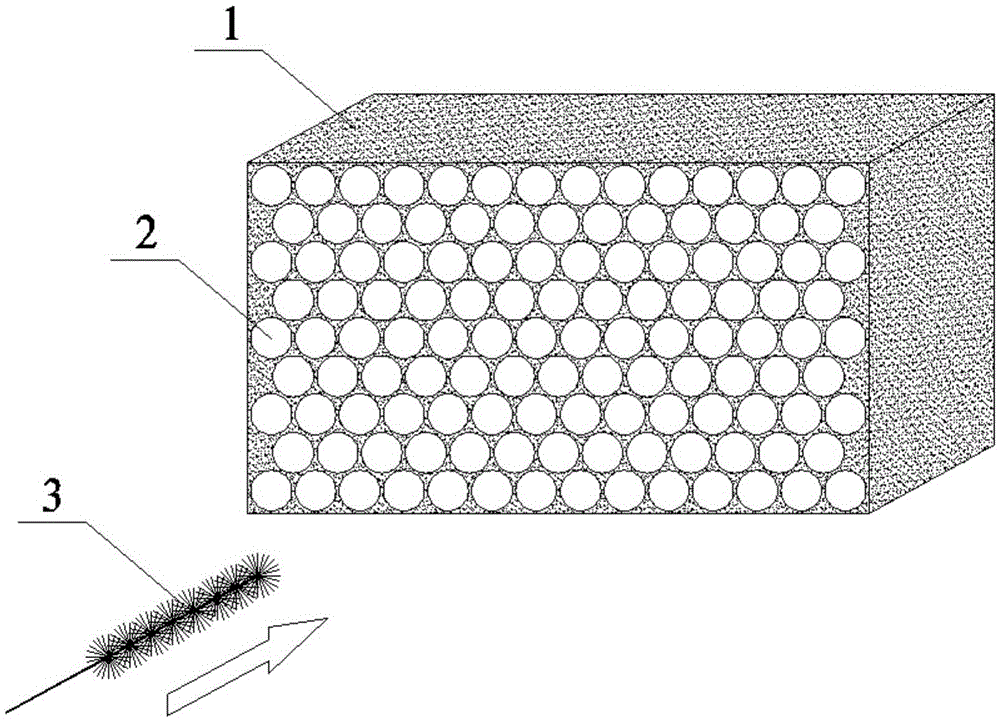

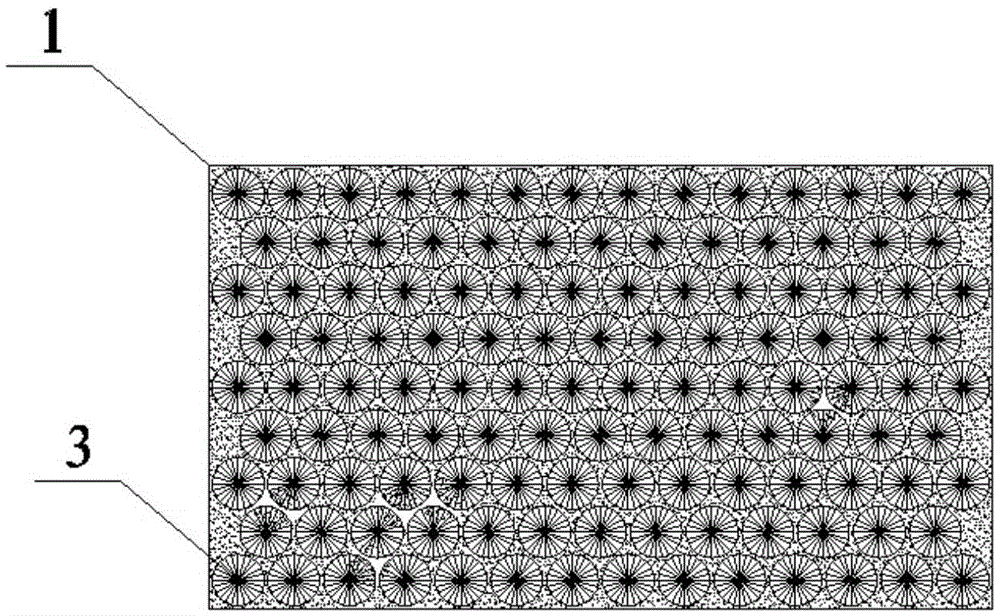

Embodiment 1

[0014] Take a polyurethane sponge with a size of 30cm×20cm×10cm, and make round holes in the direction of its thickness of 10cm. The diameter of the hole is 10mm, and the distance between the centers of the holes is 15mm. The centers of every three adjacent holes are arranged in an equilateral triangle. The number of holes is 293. Take 293 twisted wire brushes with an outer diameter of 11mm. The bristles are made of polyethylene wire and the length of the bristles is 10cm. Insert them into the pores of the polyurethane sponge and insert a brush in each hole to obtain efficient The gas purification module that captures catering waste gas oil mist droplets has a pressure drop of less than 60Pa at an air velocity of 5m / s, and its interception efficiency for droplets with a particle size of 2μm exceeds 95%.

Embodiment 2

[0016] Take a piece of polyvinyl alcohol sponge with a size of 20cm×20cm×1cm, and make a round hole in the direction of its thickness of 1cm. The diameter of the hole is 20mm, and the distance between the centers of the holes is 24mm. The centers of every three adjacent holes follow the regular triangle method. Arrangement, the number of holes is 68, take 68 twisted wire brushes, the outer diameter is 32mm, the bristle material is polypropylene wire, the length of the bristles is 1cm, insert it into the channel of the polyvinyl alcohol sponge, and insert a brush in each hole , Obtain a gas purification module that can efficiently capture oil mist droplets from catering waste gas. At an air velocity of 4m / s, the pressure drop is less than 28Pa, and the interception efficiency for droplets with a particle size of 2μm exceeds 40%.

Embodiment 3

[0018] Take a cylindrical melamine sponge with a diameter of 40cm and a height of 20cm. Make a round hole in the height direction. The diameter of the hole is 15mm. The distance between the centers of the holes is 20mm. The centers of every three adjacent holes are arranged in an equilateral triangle. The number of holes is 336. Take a twisted wire brush with an outer diameter of 20mm. The bristle material is bristle and the length of the bristle is 20cm. Insert it into the channel of the melamine sponge, and insert a brush in each hole to obtain a high-efficiency capture of catering waste gas, oil and smoke. The droplet gas purification module has a pressure drop of less than 120Pa at an air velocity of 10m / s, and its interception efficiency for droplets with a particle size of 2μm exceeds 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com