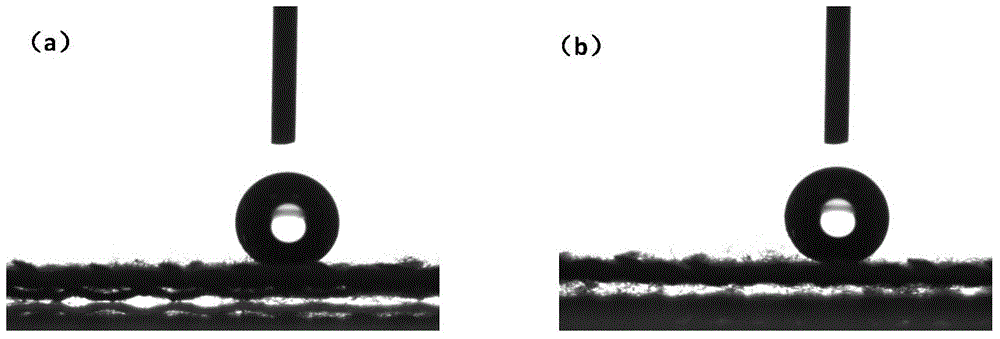

Method for preparing super-hydrophobic textiles through fiber surface polymerization modification

A fiber surface, super-hydrophobic technology, applied in the field of preparation of functional textiles, can solve the problems of high hazards for operators, weak force, and harsh equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Activate the surface of the fiber: place the polyester fabric (15cm x 25cm) in deionized water and 25g / L NaOH solution successively, wash at 80°C for 30min, then wash with dilute hydrochloric acid, deionized water and acetone for several times Once, dry at 80°C.

[0033] Step 2: Fix the initiator: Put the activated polyester fabric into a dyeing cup containing only 0.01mL 2-bromoisobutyryl bromide, heat it at 70°C for 90min, then take it out, and wash it with absolute ethanol and deionized water successively Wash several times and dry at 80°C.

[0034]Step 3: Hydrophobic modification of the fiber surface by in-situ polymerization: put the polyester immobilized with the initiator into 0.005g of CuBr, 0.005g of bipyridine, 0.04g of glucose, 60mL of tetrahydrofuran, and 0.01mL of ethyl 2-bromoisobutyrate , 8mL of a mixture of 2,2,2-trifluoroethyl methacrylate monomers, sealed, and reacted at 60°C for 8 hours. After taking it out, wash it successively with tetrahyd...

Embodiment 2

[0037] Step 1: Activate the surface of the fiber: place the polyester fabric (15cm x 25cm) in deionized water and 25g / L NaOH solution successively, wash at 80°C for 30min, then wash with dilute hydrochloric acid, deionized water and acetone for several times Once, dry at 80°C.

[0038] Step 2: Fix the initiator: Put the activated polyester fabric into a dyeing cup containing only 0.01mL 2-bromoisobutyryl bromide, heat it at 70°C for 90min, then take it out, and wash it with absolute ethanol and deionized water successively Wash several times and dry at 80°C.

[0039] Step 3: Hydrophobic modification of the fiber surface by in-situ polymerization: put the polyester with the initiator fixed in 0.005g of CuBr, 0.025g of bipyridine, 0.01g of glucose, 60mL of tetrahydrofuran, and 0.01mL of ethyl 2-bromoisobutyrate , 8mL 2,2,2-Trifluoroethyl methacrylate monomer mixture, sealed, and reacted at 60°C for 5h, after taking it out, wash it successively with tetrahydrofuran, absolute eth...

Embodiment 3

[0042] Step 1: Activate the surface of the fiber: place the polyester fabric (15cm x 25cm) in deionized water and 25g / L NaOH solution successively, wash at 80°C for 30min, then wash with dilute hydrochloric acid, deionized water and acetone for several times Once, dry at 80°C.

[0043] Step 2: Fix the initiator: Put the activated polyester fabric into a dyeing cup containing only 0.01mL 2-bromoisobutyryl bromide, heat it at 90°C for 90min, then take it out, and wash it with absolute ethanol and deionized water successively Wash several times and dry at 80°C.

[0044] Step 3: Hydrophobic modification of the fiber surface by in-situ polymerization: put the polyester immobilized with the initiator into a solution containing 0.003g of CuBr, 0.009g of bipyridine, 0.06g of glucose, 60mL of tetrahydrofuran, and 0.01mL of ethyl 2-bromoisobutyrate , 8mL of a mixture of 2,2,2-trifluoroethyl methacrylate monomers, sealed, and reacted at 50°C for 8 hours. After taking it out, wash it suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com