Novel full-automatic vertical and continuous electroplating device for PCB

A vertical continuous electroplating and fully automatic technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of serious environmental pollution, complex operation, large amount of waste water, etc., achieve uniform coating, uniform redistribution, and reduce production and operation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The following combination Attached picture The present invention is described:

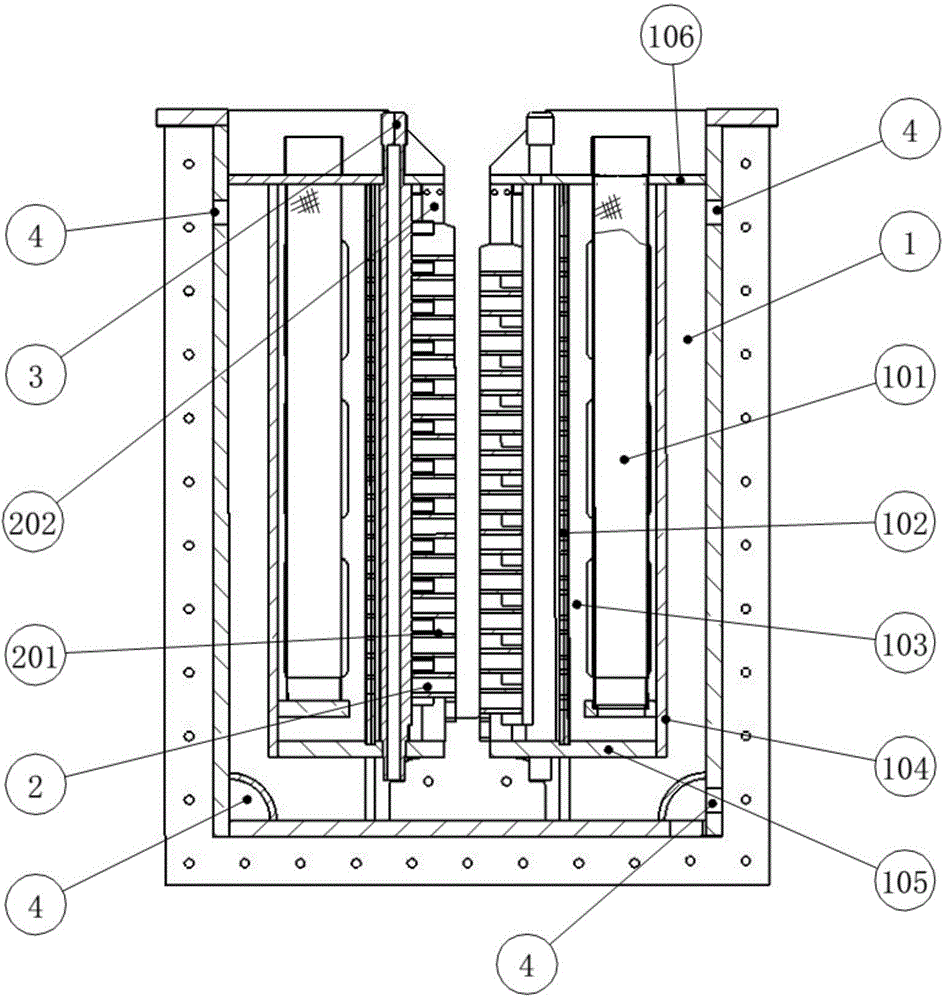

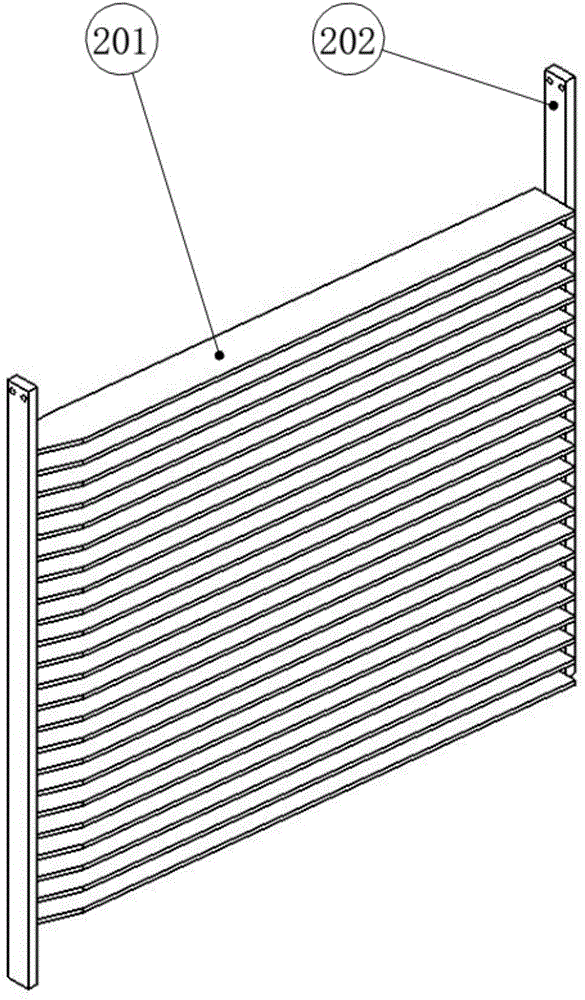

[0056] Such as figure 1 As shown in -9, in the middle part of each electroplating copper cylinder, use the tank walls on both sides as the back baffle of the middle anode chamber 1, and weld 4 side risers 103 at equal intervals on the tank walls, and the two sides of the middle chamber are on the side Leave a certain distance on the vertical plate 103 from the tank wall to weld the back baffle 104, leave a certain distance to weld the bottom plate 105 from the bottom of the tank, and the space left is used as the overflow channel 4, and the tank wall is provided with an overflow port. There are slots on both sides of the vertical plate 103 for the insertion of the diaphragm inserting plate 102. After insertion, fluorine rubber sealing strips are used to squeeze in and seal, forming several independent In the anode chamber 1, a hole is opened on the inner vertical plate 103 of each an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com