Nielsen's lead-free smelting process of lead-bearing gold concentrate

A gold concentrate and lead-forming technology, which is applied in the field of lead-free smelting process of Nielsen gravity separation of lead-containing gold concentrates, can solve the problems of not developing good process technology, large error in ore composition analysis, and sample segregation, etc. The effect of easy promotion, low production cost and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

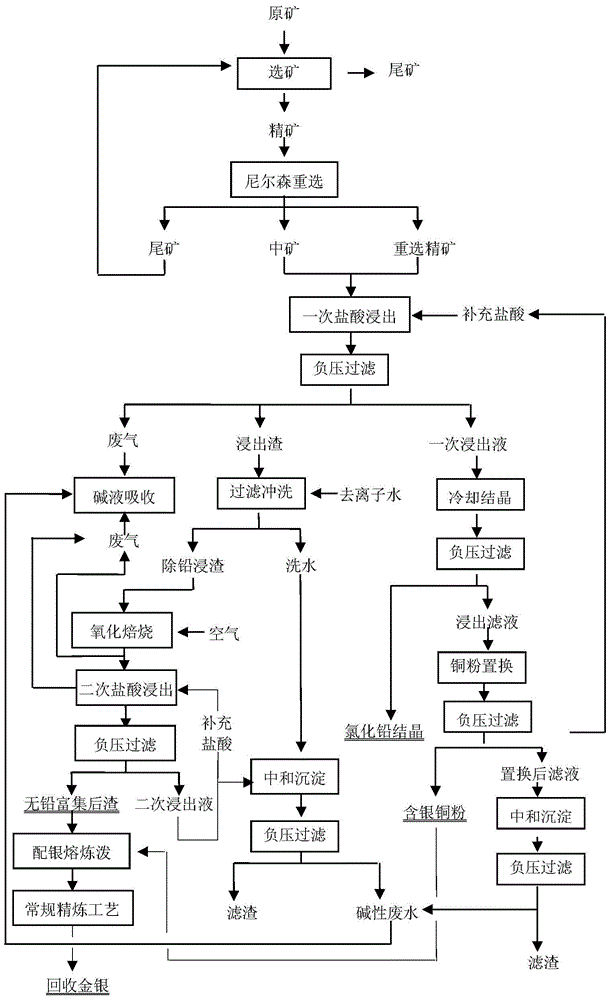

[0043] A non-pollution smelting process of Nielsen gravity-selected lead-containing gold concentrate, comprising the following steps:

[0044] Step 1. Add 50 kilograms of lead-containing middling ore in Nielsen gravity separation containing 40,000 grams / ton of gold into a polytetrafluoroethylene-lined reactor with a capacity of 1.5 cubic meters, and inject 1,000 liters of concentrated hydrochloric acid with a concentration of 6mol / L. The liquid-solid ratio (ml / g) of a hydrochloric acid leaching is about 20:1, heating and stirring for 2 hours, and the leaching temperature is 98°C;

[0045] Step 2. Inject the mixture after leaching in step 1 into a polypropylene vacuum filter while it is hot and filter under negative pressure to obtain leaching residue and primary leaching solution. Deionized water is directly filtered and rinsed, the temperature of deionized water is 90°C, and the water consumption is 1250 liters. After the washing is completed, washing water and lead removal l...

Embodiment 2

[0055] A non-pollution smelting process of Nielsen gravity-selected lead-containing gold concentrate, comprising the following steps:

[0056] Step 1, adding 10 kilograms of Nielsen's gravity-selected lead-containing gravity-selected concentrate containing 100,000 grams / ton of gold in 200 liters of glass reactors, injecting concentration is 200 liters of concentrated hydrochloric acid of 12mol / L, and the liquid-solid ratio of a hydrochloric acid leaching ( ml / g) is about 20:1, heated and stirred for leaching for 0.5 hours, and the leaching temperature is 95°C;

[0057] Step 2. Inject the mixture after leaching in step 1 into a ceramic filter while it is hot and filter under negative pressure to obtain leaching slag, primary leaching solution, and inject the primary leaching solution into the enamel crystallization reactor. The leaching residue in the form of filter cake is deionized with hot The water is directly filtered and rinsed. The deionized water temperature is 92°C and...

Embodiment 3

[0067] A non-pollution smelting process of Nielsen gravity-selected lead-containing gold concentrate, comprising the following steps:

[0068] Step 1. Add 50 kg of Nelson gravity-selected lead-containing gravity-selected concentrate containing 80,000 grams / ton of gold into an enamel reaction kettle with a capacity of 1.5 cubic meters, and inject 1,200 liters of concentrated hydrochloric acid with a concentration of 8mol / L. The liquid-solid ratio (ml / g) is about 24:1, heated and stirred for 1 hour, and the leaching temperature is 96°C;

[0069] Step 2. Inject the mixture after leaching in step 1 into a belt filter while it is hot and filter under negative pressure to obtain leaching residue, primary leaching solution, and inject the primary leaching solution into the enamel crystallization reactor. The leaching residue in the form of filter cake is removed with hot water Ionized water is directly filtered and rinsed. The temperature of deionized water is 95°C, and the water con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com