Photocatalytic antibacterial biomass wood-plastic composite material and preparation method thereof

A technology of wood-plastic composite materials and biomass, which is applied in the field of photocatalytic antibacterial biomass wood-plastic composite materials and its preparation, can solve the problems of poor bactericidal effect of microorganisms, large influence, and poor wood-plastic, etc., and achieve long-term High-efficiency multiple sterilization, strong adsorption performance, and the effect of solving discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

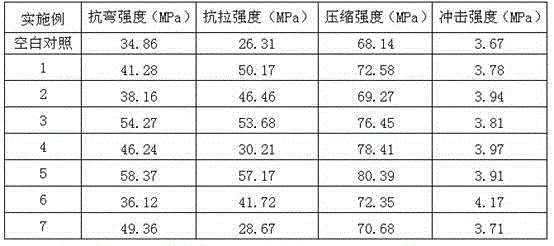

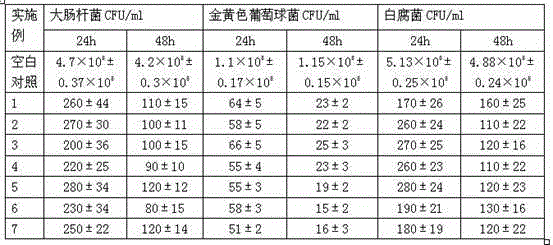

Examples

Embodiment 1

[0022] Example 1: The photocatalytic antibacterial biomass wood-plastic composite material adopts the following raw material ratio and preparation method.

[0023] The biomass wood-plastic composite material is composed of the following components: 35 parts of waste PE plastic, 70 parts of waste poplar wood powder, 12 parts of talcum powder, modified nano-TiO 2 Ag + 、Cu 2+ 3 parts of composite antibacterial agent powder, 2 parts of aluminum hydroxide, 6 parts of TWP104 produced by Struktol Company of the United States, 5 parts of bis(dioctyl pyrophosphate) glycolate titanate, 5 parts of toughening agent, antioxidant 5 parts of agent, 4 parts of light / heat stabilizer, 4 parts of colorant.

[0024] Preparation process: (1) Take modified nano-TiO 2 Ag + 、Cu 2+ Compound antibacterial agent powder, lubricant, flame retardant, and inorganic filler are added to a high-speed mixer for high-speed mixing, fully mixed evenly, and an antibacterial additive mixture is obtained, whic...

Embodiment 2

[0031] Embodiment 2: The biomass wood-plastic composite material adopts the following raw material ratio and preparation method.

[0032] The biomass wood-plastic composite material is composed of the following components: 25 parts of waste PP plastic, 75 parts of waste birch powder, 20 parts of fly ash, modified nano-TiO 2 Ag + 、Cu 2+ 8 parts of composite antibacterial agent powder, 4 parts of decabromodiphenyl ether, 1 part of stearic acid, 8 parts of maleic anhydride grafted polyethylene, 6 parts of toughening agent, and 6 parts of light / heat stabilizer.

[0033] The preparation process is the same as in Example 1 except for the following differences: (2) When the temperature is heated to 80°C, stop the machine and reduce the speed and open the large cover of the high mixer; when the temperature is heated to 130°C, put the material into the cold mixer The cylinder is cooled to 50°C to obtain the mixed material, and the material is discharged for later use. The obtained ...

Embodiment 3

[0037] Embodiment 3: The biomass wood-plastic composite material adopts the following raw material ratio and preparation method.

[0038] The biomass wood-plastic composite material is composed of the following components: 40 parts of waste PVC plastic, 63 parts of cotton straw powder, 18 parts of blast furnace ash, modified nano-TiO 2 Ag + 、Cu 2+ 10 parts of compound antibacterial agent powder, 1 part of melamine, 10 parts of PE wax, 2 parts of PA series high-efficiency lubricating dispersion compatible coupling agent, 8 parts of toughening agent, 5 parts of antioxidant, 8 parts of light / heat stabilizer, Coloring agent 4 parts.

[0039] The preparation process is the same as in Example 1 except for the following differences: (2) When the temperature is heated to 100°C, stop the machine and reduce the speed and open the cover of the high-mixer; when the temperature is heated to 120°C, put the material into the cold mixer The cylinder is cooled to 50°C to obtain the mixed m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com