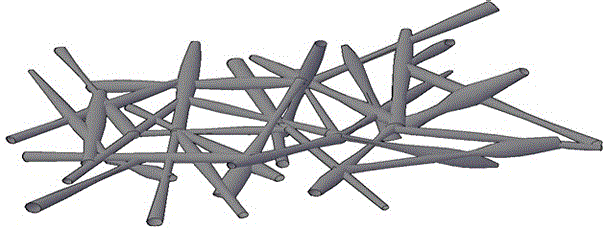

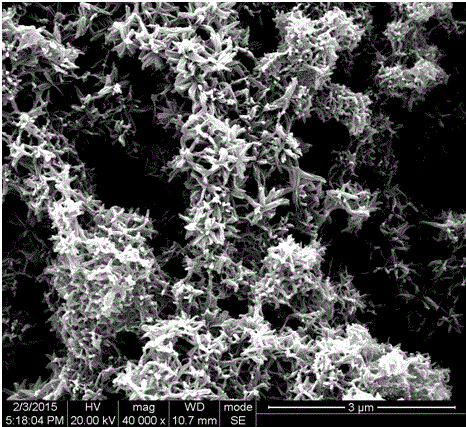

A kind of preparation method of rattan-shaped three-dimensional nanostructured nickel cobaltate material

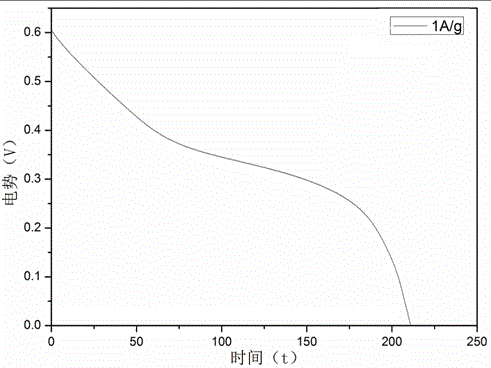

A three-dimensional nano, nickel cobalt oxide technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of difficult electron transport network channels, the specific surface area needs to be improved, and the electrical conductivity is not very good, so as to improve the reaction speed, excellent electrochemical activity, and the effect of fast charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Prepare 0.1-3mol / L solutions with nickel nitrate and cobalt nitrate respectively.

[0036] 2. Take 5ml and 10ml of the nickel nitrate and cobalt nitrate solutions prepared in step 1, mix them, and magnetically stir them evenly to prepare solution A.

[0037] 3. Then prepare a starch solution of 0.1-20g / L, take 50ml of the solution and drop it into solution A, stir evenly to prepare solution B.

[0038] 4. Add urea into the above mixed liquid B, the concentration range of urea is 0.05-10.0mol / L, and then stir evenly to obtain mixed liquid C.

[0039] 5. Move C into a metal reactor, and react hydrothermally at a temperature of 70-220° C. for 1-36 hours to prepare nickel cobaltate precursor material D.

[0040] 6. Centrifuge D, wash it with deionized water and propanol respectively, and after several times of centrifugal washing, dry it in the air or in a protective gas to obtain the precursor E.

[0041] 7. Heat E to 400°C for 5 hours in an air atmosphere.

Embodiment 2

[0043] 1. Prepare 0.1-3mol / L solutions with nickel nitrate and cobalt nitrate respectively.

[0044] 2. Take 5ml and 10ml of the nickel nitrate and cobalt nitrate solutions prepared in step 1, mix them, and magnetically stir them evenly to prepare solution A.

[0045] 3. Then prepare 0.01-20.0g / L sodium polystyrene sulfonate, take 50ml of the solution and drop it into solution A, stir while dripping, after stirring evenly, make solution B.

[0046] 4. Add urea to the above mixed solution B, the concentration range of urea is 0.05-5.0mol / L, then stir evenly until mixed solution C.

[0047] 5. Move C into a metal reactor, and conduct a hydrothermal reaction at a temperature of 70°C for 36 hours to prepare nickel cobaltate precursor material D.

[0048] 6. Suction filter D, wash with deionized water and propanol respectively, centrifuge and wash several times, and dry to obtain precursor E.

[0049] 7. Heat E to 500°C for 6 hours in an air atmosphere.

Embodiment 3

[0051] 1. Prepare 0.1-3mol / L solutions with nickel nitrate and cobalt nitrate respectively.

[0052] 2. Take 5ml and 10ml of the nickel nitrate and cobalt nitrate solutions prepared in step 1, mix them, and magnetically stir them evenly to prepare solution A.

[0053] 3. Then prepare 0.01-20.0g / L sodium polystyrene sulfonate, take 50ml of the solution and drop it into solution A, stir while dripping, and make solution B after the stirring time is uniform.

[0054] 4. Add urea to the above mixed liquid B, control the concentration range of urea to 0.05-5.5mol / L, and then stir to obtain mixed liquid C.

[0055] 5. Move C into an oil bath, and react in an oil bath at a temperature of 220° C. for 2 hours to prepare nickel cobaltate precursor material D.

[0056] 6. Centrifuge D, wash with deionized water and propanol respectively, and after several times of centrifugal washing, dry to obtain precursor E.

[0057] 7. Heat E to 700°C for 1 hour in an air atmosphere.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com