Superfine emulsified wax molding agent suitable for cemented carbide water-based mixture and preparation method

A cemented carbide and mixed material technology, applied in the field of powder metallurgy, can solve the problems of emulsifier influence, emulsification wax breaking, unenvironmental protection, etc., and achieve the effect of reducing the difficulty of unloading and improving the efficiency of ball milling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] An ultrafine emulsified wax forming agent suitable for cemented carbide water-based mixture and its preparation method according to the present invention, through the optimization and screening of emulsifier and emulsification process, a kind of ultrafine emulsified wax is prepared, which can be used in slurry ball milling Add directly to the mix.

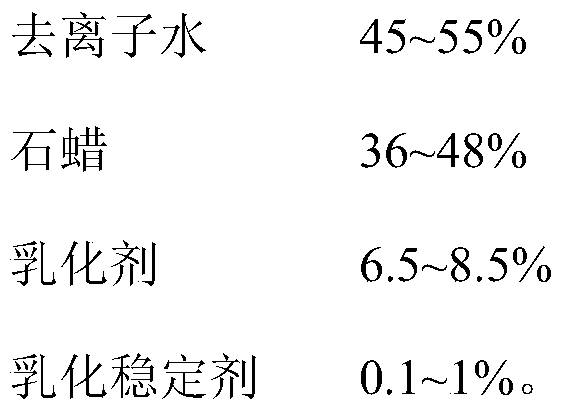

[0025] A kind of ultra-fine emulsified wax forming agent suitable for cemented carbide water-based mixture of the present invention is made up of the following components by weight percentage:

[0026]

[0027] Further, the superfine emulsified wax molding agent suitable for cemented carbide water-based mixture is composed of the following components by weight percentage:

[0028]

[0029]

[0030] A kind of preparation method of the superfine emulsified wax molding agent that is applicable to cemented carbide water-based mixture of the present invention comprises the following steps:

[0031] Calculated by weight ...

Embodiment 1

[0042] Weigh 570g of paraffin (38wt.%), 97.5g of emulsifier (6.5wt.%) and 7.5g of emulsion stabilizer (0.5wt.%), set the temperature in a water bath to 85°C, and heat until the mixture is completely in solution , standby; another weigh 825g deionized water (55wt.%), placed in a water bath and heated to 85 ℃, standby; deionized water is poured into the mixture containing paraffin, and high-dispersion emulsification device is used to carry out high-speed emulsification of the solution Mechanical stirring, the stirring speed is adjusted to 10000r / min, and the stirring time is 30min; after the emulsification is completed, the emulsion is placed in the air and naturally cooled to room temperature.

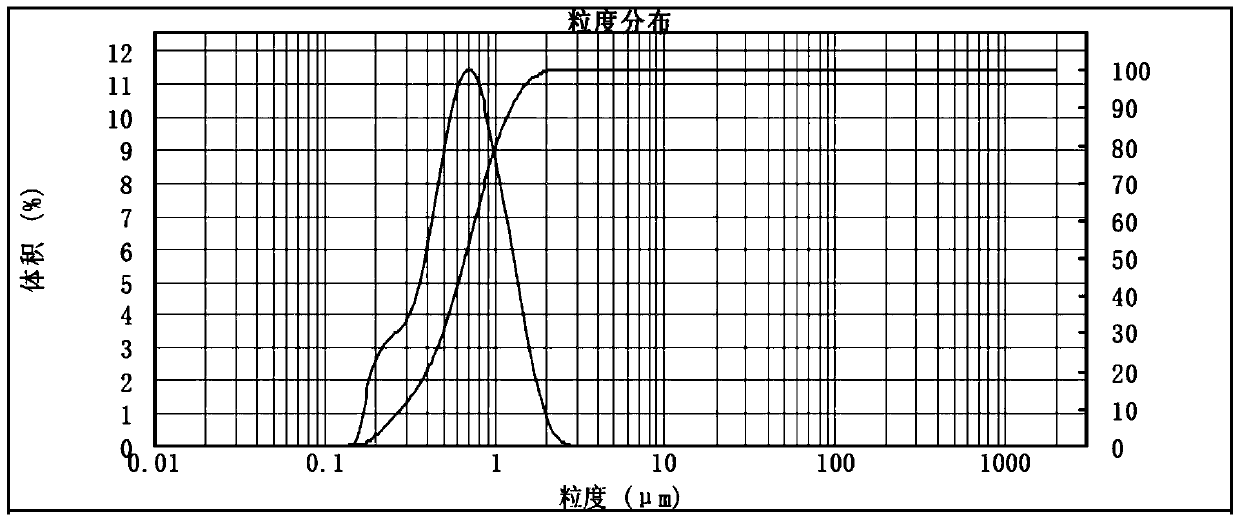

[0043] Use a laser particle size analyzer to detect the particle size distribution of emulsified wax, such as figure 1 As shown, the results are: D(0.1) is 0.290um, D(0.5) is 0.671um, and D(0.9) is 1.281um.

[0044] Prepare a batch of 3kg water-based mixture with the conventional ball ...

Embodiment 2

[0046] Weigh 643.5g paraffin (42.9wt.%), 105g emulsifier (7wt.%) and 1.5g emulsion stabilizer (0.1wt.%), set the temperature in a water bath to 85°C, and heat until the mixture is completely in solution , for standby; another 750g deionized water (50wt.%) was weighed, placed in a water bath and heated to 85°C for standby; deionized water was poured into the mixture containing paraffin, and the solution was subjected to high-speed emulsification with a high-dispersion emulsification device. Mechanical stirring, the stirring speed is adjusted to 15000r / min, and the stirring time is 20min; after emulsification, the emulsion is placed in the air and naturally cooled to room temperature.

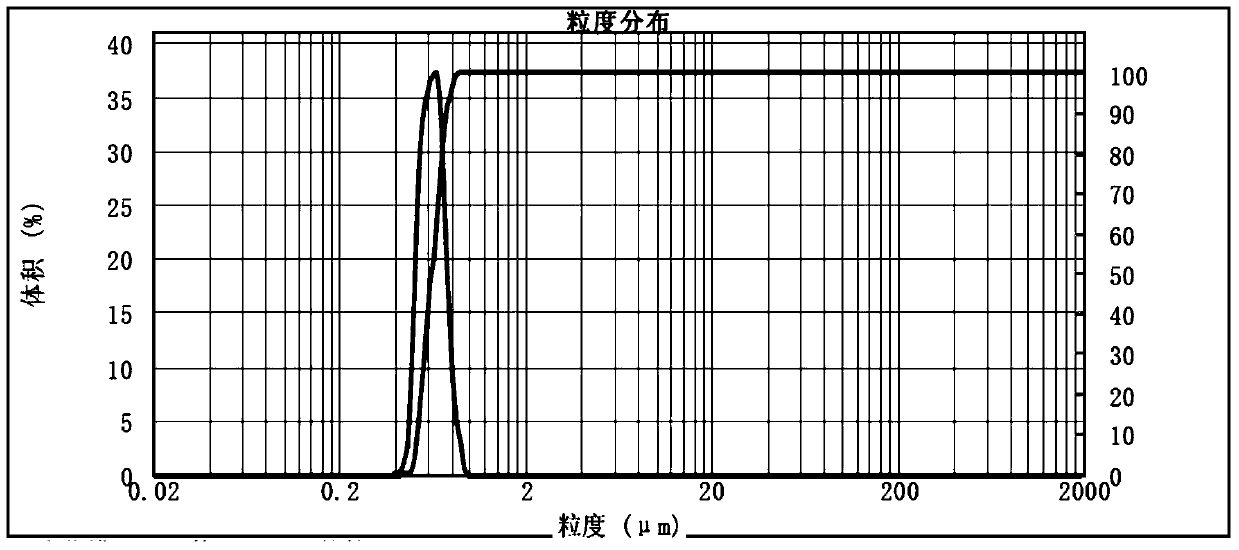

[0047] Use a laser particle size analyzer to detect the particle size distribution of emulsified wax, such as figure 2As shown, the results are: D(0.1) is 0.524um, D(0.5) is 0.628um, and D(0.9) is 0.752um.

[0048] Prepare a batch of 3kg water-based mixture with the conventional ball milling pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com