Electro-hydraulic forming device for pipe fitting and forming method

A technology of electro-hydraulic forming and pipe fittings, which is applied in the field of electro-hydraulic forming devices for pipe fittings, which can solve the problems of inability to use pipe fittings for bulging, and achieve the effects of changing the effect of bulging, uniform pressure, and improving plastic deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

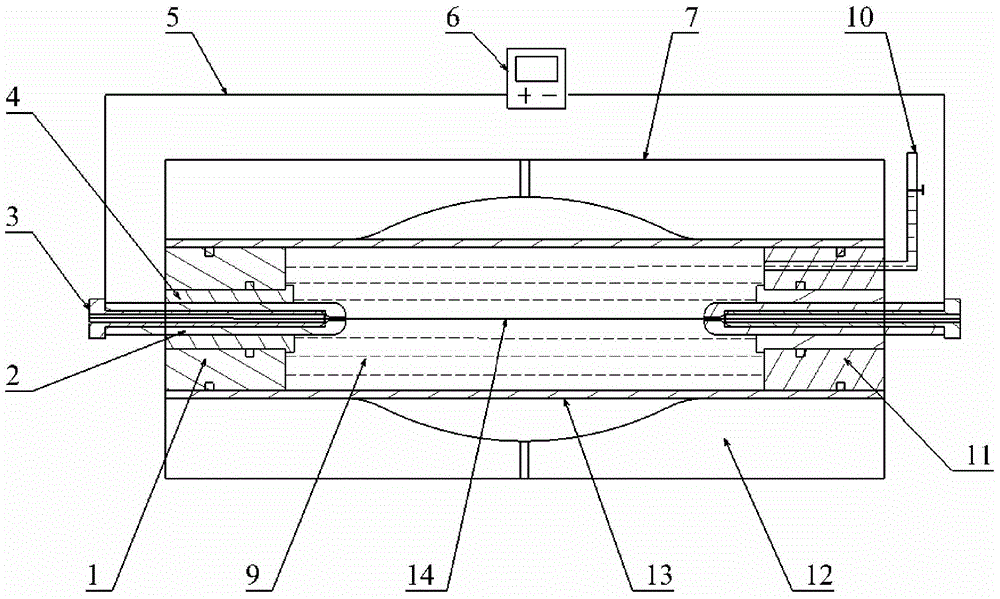

[0039] This embodiment is an electro-hydraulic forming device that realizes pipe forming through bulging.

[0040] This embodiment includes a bulging mold, a power source 6, a water pipe 10, a water storage tank 8, a water medium 9, a metal wire 14, a positive electrode and a negative electrode.

[0041] In this embodiment, the upper mold 7 and the lower mold 12 are combined to form a bulging mold for the pipe, and the pipe 13 to be formed is placed in the cavity of the bulging mold. The positive electrode is installed at one end of the pipe to be formed, and the negative electrode is installed at the other end of the pipe to be formed. The positive electrode is connected to the positive pole of the power supply 6 through the wire 5 , and the negative electrode is connected to the negative pole of the power supply 6 through the wire 5 . The metal wire 14 is located at the center of the pipe to be formed 13, and coincides with the axis of the pipe to be formed 13; the two ends...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com