Polishing tool for scale in oil tube

A technology for grinding tools and dirt, which is applied to the field of grinding tools for dirt in oil pipes, can solve the problems of troublesome oil pipe cleaning, high cost, incomplete cleaning, etc., and achieves the effect of solving the trouble of cleaning, improving efficiency and improving cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

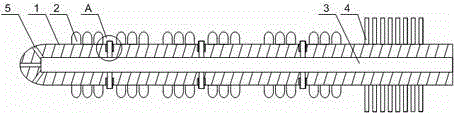

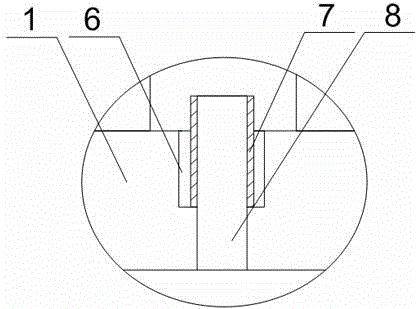

[0020] Such as figure 1 with figure 2 As shown, this embodiment includes a support cylinder 1 with a water injection channel 3 inside and a bristle brush 4 fixed at the end of the support cylinder 1, and a plurality of knife sets are arranged at intervals on the support cylinder 1 2, and there is a gap in the middle of the knife set 2, an inwardly recessed swing cavity 6 is provided on the support cylinder 1, and a radial water spray communicated with the water injection channel 3 is opened on the top of the swing cavity 6 Hole 8, the top of radial spray hole 8 is fixed with the water spray hose 7 that can move freely in the swing chamber 6, and the movable end of the water spray hose 7 protrudes from the upper end of the swing chamber 6 and is placed In the gap; the front end of the support cylinder 1 is provided with a plurality of water spray holes 5 communicating with the water injection channel 3; The heart radiates outward.

[0021] In view of the poor effect of chem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com