PVDF nano fiber multifunctional air filtering material and preparation method thereof

An air filter material and nanofiber technology, applied in the field of filter materials, can solve problems such as single function, reduced filter performance, and defective filter efficiency, and achieve the effect of simple preparation and improved temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

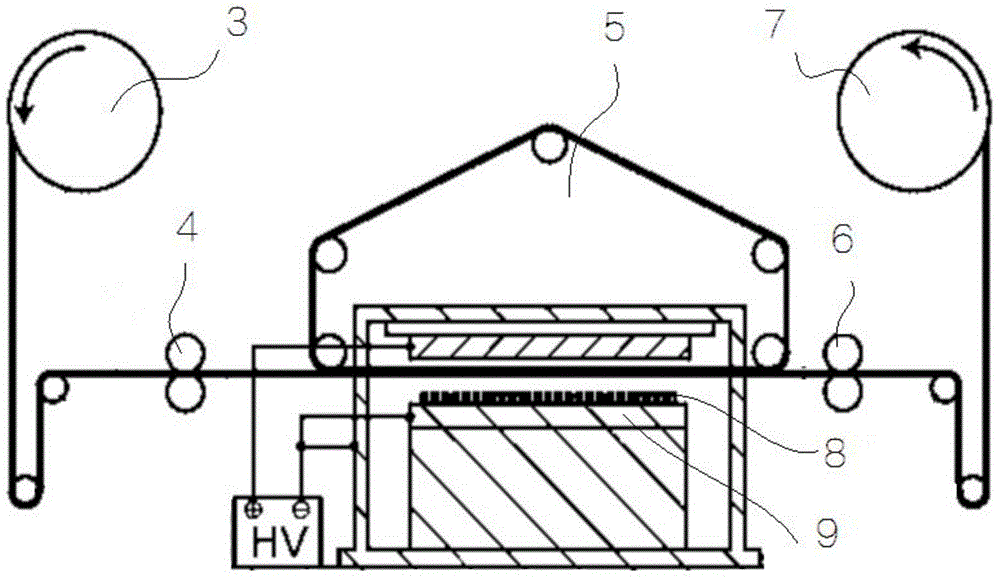

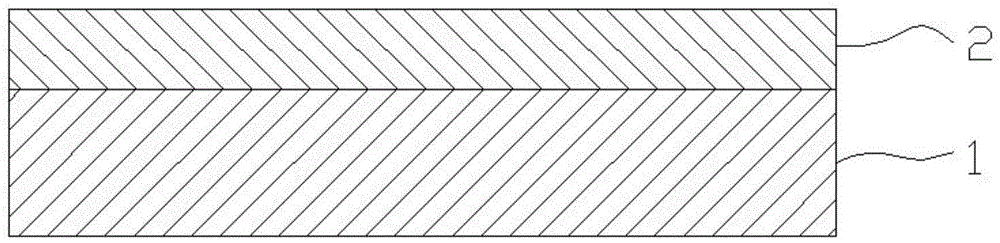

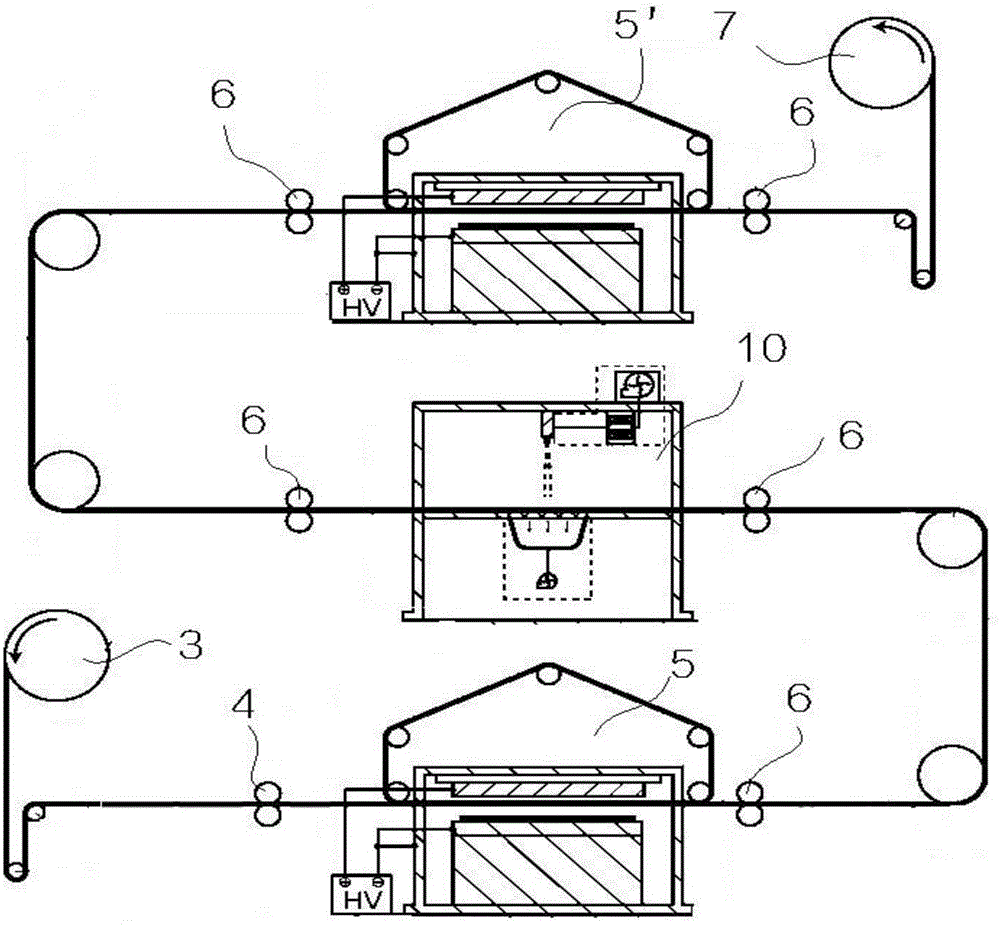

[0034] refer to figure 1 and figure 2 Shown, a kind of PVDF nanofiber multifunctional air filter material, comprise one deck polypropylene microfiber layer 1 and one deck PVDF nanofiber layer 2, PVDF nanofiber is made by spinning solution, and spinning solution comprises the PVDF resin of 1kg , 9kg of mixed solvent, the mixed solvent includes 4.5kg of amide solvent and 4.5kg of ketone, the amide solvent is N,N-dimethylformamide, and the ketone is butanone. PVDF nanofibers also include 0.01kg of tetrabutylammonium perchlorate, which is used to increase the conductivity of the solution and increase the degree of fiber splitting during electrospinning, thereby obtaining finer nanofibers , which can ensure the complete volatilization of the solvent in the spinning solution; the tetrabutyl ammonium perchlorate salt contained in the formed PVDF nanofiber layer can increase the amount of static charge of the PVDF fiber, making the PVDF nanofiber layer also become an electret , to ...

Embodiment 2

[0045] The difference between embodiment two and embodiment one is that the spinning solution includes 1kg of PVDF resin and 13kg of mixed solvent, the mixed solvent includes 10kg of amide solvent and 3kg of ketone, and the amide solvent is N,N-dimethylethyl Amide, ketone is acetone. PVDF nanofibers also include 0.007kg of tetrabutylammonium perchlorate

[0046] The fiber diameter of the polypropylene micron fiber layer is 1 micron, the temperature of the high-temperature calender roll is 40°C, and the pressure is 1000N / ㎡, the temperature of the low-temperature calender roll is 30°C, and the pressure is 1000N / ㎡. The flow rate of the silk needle is 0.1ml / h, and the spinning voltage of the electrospinning device is 20kv.

[0047] The finished product obtained in this embodiment has a filtration efficiency of more than 90% for 0.075 micron sodium chloride aerosol, a pressure drop resistance of less than 100 Pa, and a bacteriostasis rate of more than 80% for Escherichia coli.

Embodiment 3

[0049] The difference between Embodiment 3 and Embodiment 1 is that the fiber diameter of the polypropylene micron fiber layer is 3 microns, the temperature of the high-temperature calender roll is 80°C, and the pressure is 5000N / ㎡, the temperature of the low-temperature calender roll is 60°C, and the pressure The flow rate of the spinning needle of the electrospinning device is 0.5ml / h, and the spinning voltage of the electrospinning device is 60kv.

[0050] The finished product obtained in this embodiment has a filtration efficiency of more than 90% for 0.075 micron sodium chloride aerosol, a pressure drop resistance of less than 100 Pa, and a bacteriostasis rate of more than 80% for Escherichia coli.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com