Corrosion inhibitor for recirculated cooling water

A technology of circulating cooling water and corrosion inhibitor, which is applied in the fields of descaling and water softening, water/sludge/sewage treatment, chemical instruments and methods, etc. Poor synergy, environmental pollution and other problems, to achieve the effect of strengthening corrosion inhibition, avoiding corrosion, and improving corrosion inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

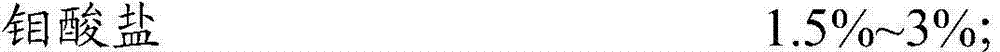

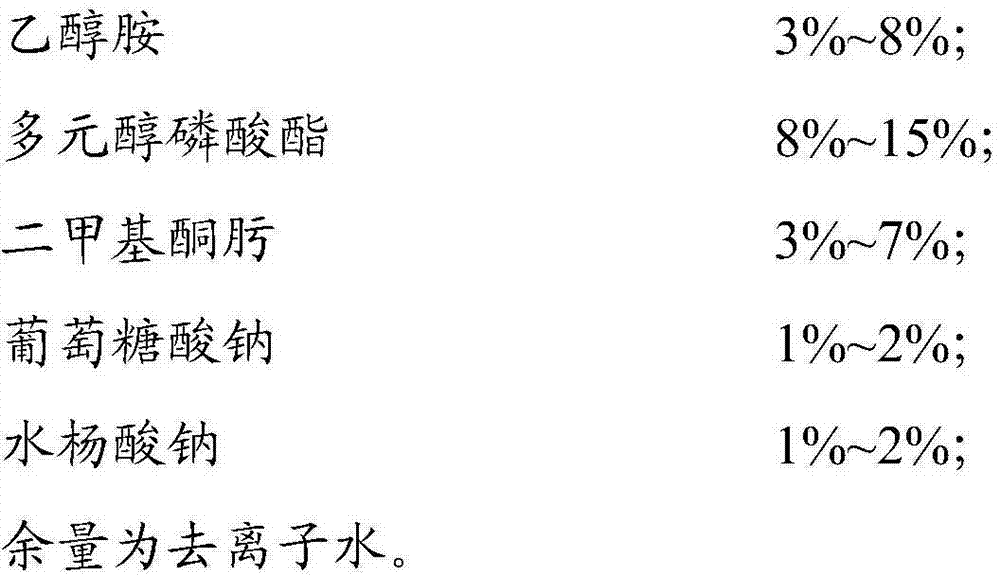

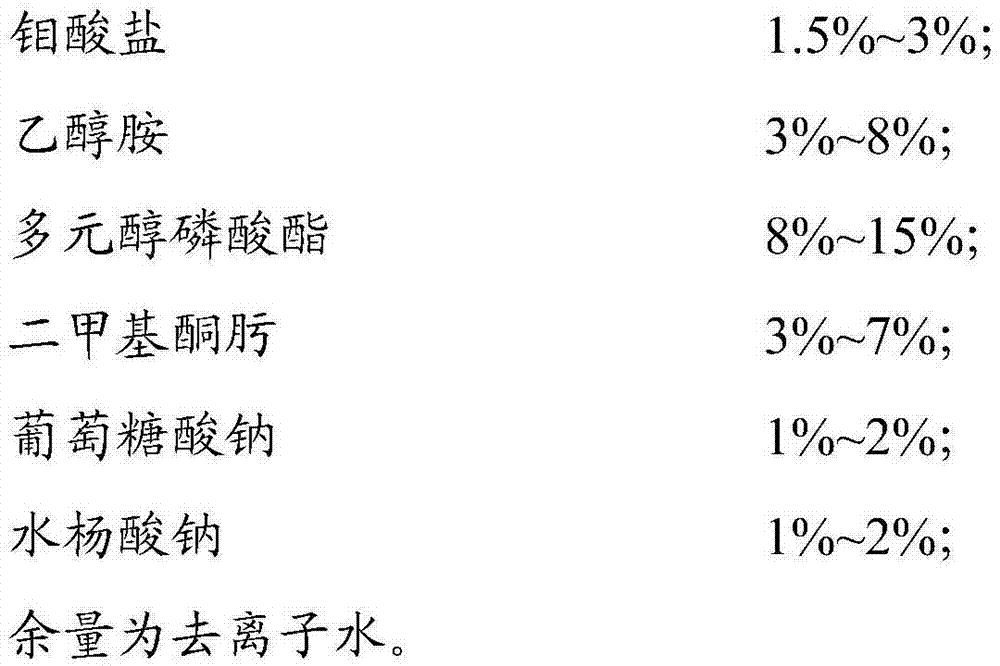

[0015] The raw material ratio (by weight) for preparing the corrosion inhibitor of the present invention is as follows: 1.5% molybdate, 3% triethanolamine, 8% polyol phosphate (PAPE), 3% dimethyl ketoxime, gluconic acid Sodium 1%, Sodium Salicylate 1.5%, Deionized Water 82%.

[0016] Using the raw materials in the above ratio, the corrosion inhibitor is prepared through the following steps: add the above-mentioned amount of dimethyl ketone oxime to the deionized water containing the above-mentioned amount, and then add the above-mentioned amount of other raw materials into the container and stir evenly, that is Obtain the corrosion inhibitor of the present invention. It has been verified by experiments that when heated to a high temperature of 80 degrees Celsius, the corrosion inhibition rate of this corrosion inhibitor on copper sheets is as high as 83.2%.

[0017] Preferably, the molybdate may be one of sodium molybdate or potassium molybdate, or a mixture of the above two....

Embodiment 2

[0020] The raw material ratio (by weight) for preparing the corrosion inhibitor of the present invention is as follows: 2% molybdate, 4% mixture of triethanolamine and diethanolamine, 13% polyol phosphate (PAPE), dimethyl ketoxime 5%, sodium gluconate 1.5%, sodium salicylate 2%, deionized water 72.5%.

[0021] Using the raw materials in the above ratio, the corrosion inhibitor is prepared through the following steps: add the above-mentioned amount of dimethyl ketone oxime to the deionized water containing the above-mentioned amount, and then add the above-mentioned amount of other raw materials into the container and stir evenly, that is Obtain the corrosion inhibitor of the present invention. It has been verified by experiments that when heated to a high temperature of 80 degrees Celsius, the corrosion inhibition rate of this corrosion inhibitor on copper sheets is as high as 84%.

Embodiment 3

[0023] The raw material ratio (by weight) for preparing the corrosion inhibitor of the present invention is as follows: 3% sodium molybdate, 8% triethanolamine, 15% polyol phosphate (PAPE), 5% dimethyl ketoxime, gluconic acid Sodium 1%, Sodium Salicylate 1.5%, Deionized Water 66.5%.

[0024] Using the raw materials in the above ratio, the corrosion inhibitor is prepared through the following steps: add the above-mentioned amount of dimethyl ketone oxime to the deionized water containing the above-mentioned amount, and then add the above-mentioned amount of other raw materials into the container and stir evenly, that is Obtain the corrosion inhibitor of the present invention. It has been verified by experiments that when heated to a high temperature of 80 degrees Celsius, the corrosion inhibition rate of this corrosion inhibitor on copper sheets is as high as 88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com