A kind of finishing method of polyester or brocade hydrophobic fabric based on paa-teos-oa joint treatment

A PAA-TEOS-OA combined treatment technology, applied in fiber treatment, textile and papermaking, fiber type, etc., can solve environmental problems, application restrictions and other problems, achieve good static contact angle of water droplets, avoid environmental problems, whiteness increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Fabric: Polyester woven fabric (50D*50D / 168*128)

[0029] 1) Prescription: 2g / L accelerator (cationic surfactant 1227)

[0030] NaOH concentration is 5%

[0031] Method: liquor ratio: 1:30

[0032] Temperature: 90°C

[0033] Time: 10 minutes

[0034] 2) Prescription: 4g / L polyacrylic acid (molecular weight 240000)

[0035] Method: Stir and soak for 12 hours, the excess rate is 110%, bake at 120°C for 3 minutes.

[0036] 3) Prescription: tetraethyl orthosilicate 5%

[0037] Ethanol: water = 7:3

[0038] Ammonia 5%

[0039] Method: Dip for 2 hours and bake at 90°C.

[0040] 4) Prescription: ethanol

[0041] Ammonia 4%

[0042] Octadecylamine 5%,

[0043] Method: liquor ratio: 1:20

[0044] Temperature: room temperature

[0045] Time: 12 hours

[0046] Baking: 120°C, 2 minutes

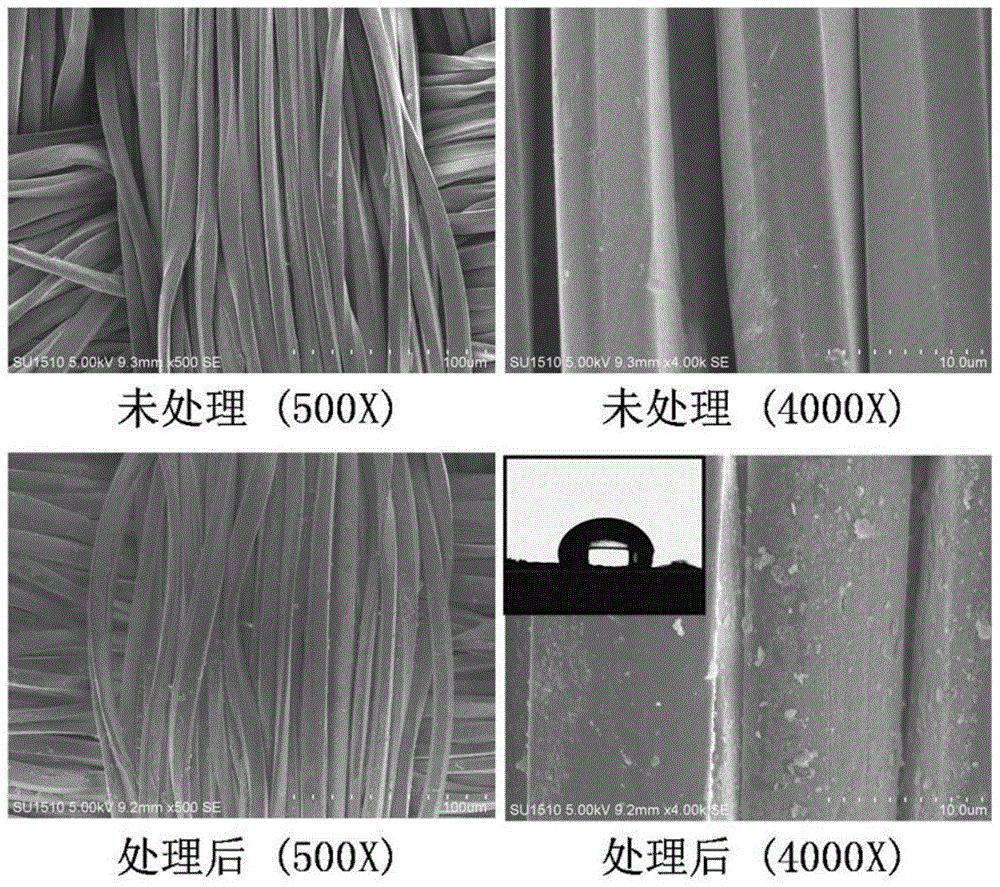

[0047] figure 1 SEM images of untreated and alkali-reduced-PAA-TEOS-OA treated polyester woven fabrics. Compared with the original polyester fabric, the surface of the treated poly...

Embodiment 2

[0056] Fabric: Nylon woven fabric (50D*50D / 109*81)

[0057] 1) Prescription: 4g / L polyacrylic acid (molecular weight 240000)

[0058] Method: Stir and soak for 20 hours, bake at 120°C for 2 minutes.

[0059] 2) Prescription: tetraethyl orthosilicate 3%

[0060] Ethanol: water = 7:3

[0061] Ammonia 5%

[0062] Method: Bath ratio: 1:30

[0063] Temperature: room temperature

[0064] Time: 4 hours

[0065] 3) Prescription: ethanol

[0066] Ammonia 1%

[0067] Octadecylamine 3%,

[0068] Method: Bath ratio: 1:30

[0069] Temperature: room temperature

[0070] Time: 12 hours

[0071] Baking: 150°C, 5 minutes

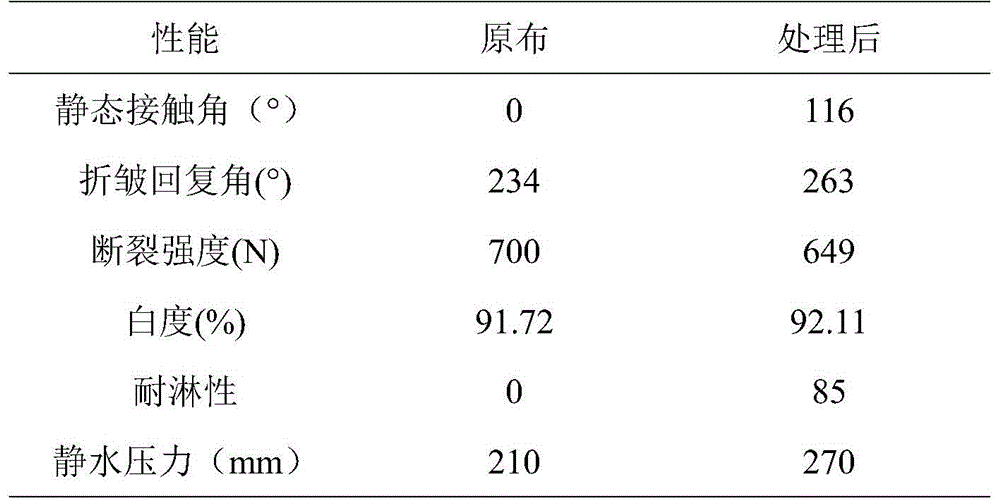

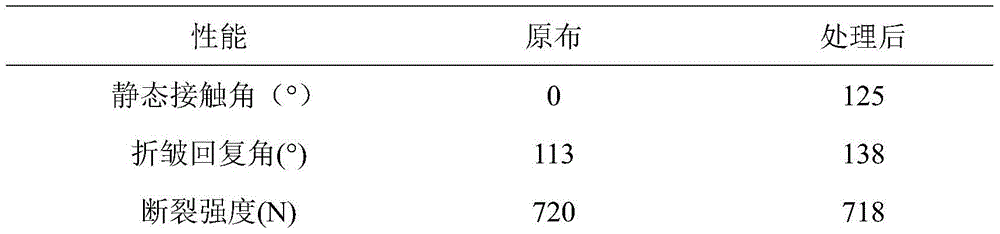

[0072] The water resistance and physical properties of nylon before and after the method of the present invention are treated are as shown in Table 2. The results show that the static contact angle, spray resistance and hydrostatic pressure resistance of the fabric are significantly improved, indicating that the product prepared by the invention has good hydroph...

Embodiment 3

[0080] Use the following method to process nylon woven fabric (50D*50D / 109*81):

[0081] (1) Polyacrylic acid treatment: add 2 g / L of polyacrylic acid (molecular weight: 5000) solution to the fabric, stir and impregnate for 12 hours, take out the fabric, roll it once on a padding machine, bake at 80°C for 1 minute, fully wash with water after treatment, and dry;

[0082] (2) Tetraethyl orthosilicate treatment: the mixture of propanol and water is the reaction solution, the ratio is 9:1, the concentration of tetraethyl orthosilicate is 2%, the pH is 3, and 2% of tetraethyl orthosilicate is added after 2 hours of fabric treatment. Ammonia, treated for 5 hours, fully washed with water after treatment, and dried;

[0083] (3) Octadecylamine treatment: Add ethanol, 1% ammonia water, and 2% octadecylamine at a bath ratio of 1:15. After the fabric is treated for 2 hours, it is rolled by a paddle car and baked at 100°C for 5 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com