Microwave radiation melt method chlorination production method of chlorinated polyvinyl chloride (CPVC) resin

A technology of CPVC resin and chlorinated polyvinyl chloride, which is applied in the field of new technology and new polymer materials, and can solve the problems of short chlorination reaction time, high chlorine content, high utilization rate of liquid chlorine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

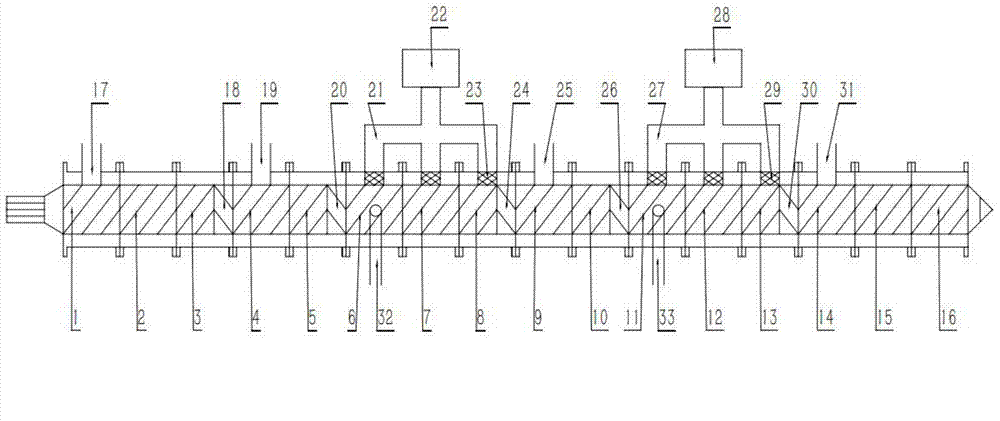

Method used

Image

Examples

Embodiment 1

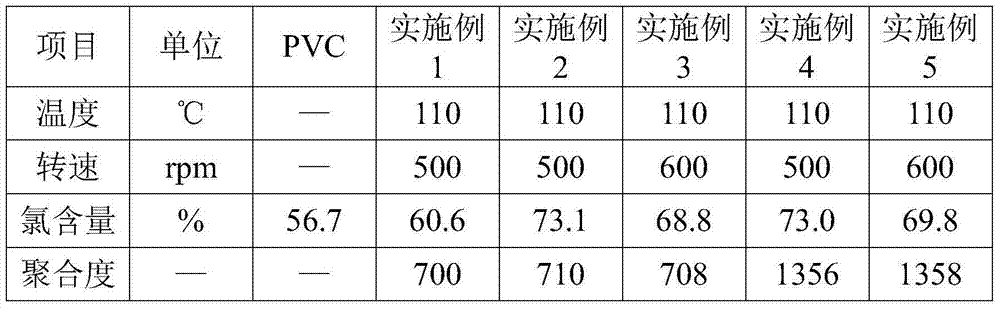

[0036] Embodiment 1: Feed 8 kg / min SG8 type polyvinyl chloride PVC resin quantitatively and uniformly in a twin-screw extruder with a diameter of 62, an aspect ratio L / D=64, a set temperature of 110° C., and a rotating speed of 500 rpm. After the material is discharged, use a liquid chlorine booster pump to inject 1 kg / min (a total of 2 kg / min) of liquid chlorine into the 6th and 11th sections of the two main inlets. The extruded product is a white resin, and the measured chlorine content is 60.6 %, the measured viscosity converted into a degree of polymerization is 700;

Embodiment 2

[0037] Embodiment 2: Feed 8 kg / min SG8 type polyvinyl chloride PVC resin quantitatively and uniformly in a twin-screw extruder with a diameter of 62, an aspect ratio L / D=64, a set temperature of 110° C., and a rotating speed of 500 rpm. After the material is discharged, use the liquid chlorine booster pump to inject 1 kg / min (2 kg / min in total) of liquid chlorine into the 6th and 11th sections of the two main inlets, and turn on the microwave radiation at the same time. The power of each magnetron is 1000W. , the power distributed to each waveguide branch is about 200W, the extruded product is a white resin, the measured chlorine content is 73.1%, and the measured viscosity is converted into a degree of polymerization of 710;

Embodiment 3

[0038] Embodiment 3: Feed 8 kg / min SG8 type polyvinyl chloride PVC resin quantitatively and uniformly in a twin-screw extruder with a diameter of 62, an aspect ratio L / D=64, a set temperature of 110° C., and a rotating speed of 600 rpm. After the material is discharged, use the liquid chlorine booster pump to inject 1 kg / min (2 kg / min in total) of liquid chlorine into the 6th and 11th sections of the two main inlets, and turn on the microwave radiation at the same time. The power of each magnetron is 1000W. , the power distributed to each waveguide branch tube is about 200W, the extruded product is a white resin, the measured chlorine content is 68.8%, and the measured viscosity converted into a degree of polymerization is 708;

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com