Truck and motor coach magnesium hub rotary-swaging forming method

A technology for trucks and buses, applied in the field of automobile manufacturing, which can solve the problems of large-size wheel hubs that are easily deformed, complex processing, and cracking of magnesium alloys, so as to save machining amount and energy consumption, reduce subsequent processing, and be easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

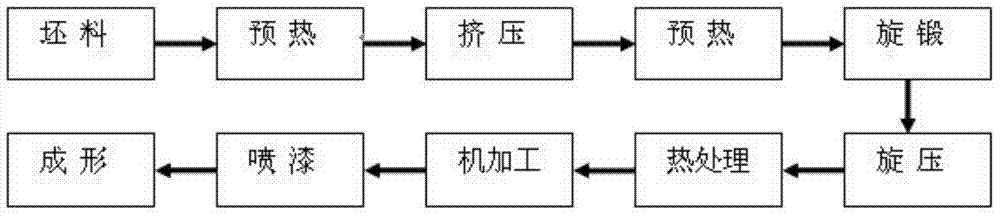

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 Production of 24-inch AZ80 magnesium alloy wheel hub

[0021] Prepare the material needed for production AZ80 magnesium alloy with a diameter of 300 mm; put the material into the furnace, raise the furnace temperature to 400 °C in 30 min, and keep it warm for 1.5 h; at the same time, put the extrusion die into the furnace , kept at 380°C for 30 min. The preheated AZ80 magnesium alloy was extruded with 30 MN. After extrusion, put the extrusion blank into the furnace, raise the furnace temperature to 450 °C for 30 minutes, and keep it for 1 hour. At the same time, put the forging mold into the furnace, and keep it for 30 minutes at 450 °C; After finishing, use an 80 MN forging press for swaging, and keep it for 30 s, spray lubricant on the mold to obtain a forging mold; use a 3000-ton vertical hub spinning machine with an automatic heating device to spin the forging blank, The spinning temperature is 400 ℃, the spindle speed is 4000 r / min, and the magnes...

Embodiment 2

[0022] Embodiment 2 Production of 22-inch ZK60 magnesium alloy wheel hub

[0023] Prepare the material ZK60 magnesium alloy required for production, with a diameter of 240 mm; put the material into the furnace, raise the temperature of the furnace to 350 °C in 30 min, and keep it warm for 1.5 h; at the same time, put the extrusion die into the furnace , kept at 350°C for 30 min. Extrude the preheated ZK60 magnesium alloy with 30MN. After extrusion, put the extrusion blank into the furnace, raise the furnace temperature to 400 °C for 30 minutes, and keep it for 1 hour. At the same time, put the forging mold into the furnace, and keep it for 30 minutes at 420 °C; Finally, swivel forging with an 80 MN forging press, and keep it for 10 s, spray lubricant on the mold to obtain a forging die; use a 3000-ton vertical hub spinning machine with an automatic heating device to spin the forging blank, spin The pressing temperature is 320 ℃, the spindle speed is 3000 r / min, and the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com