A kind of heterogeneous cu-mn-ce class fenton catalyst and its preparation method and application

A heterogeneous catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of uneven dispersion of active components, small contact surface, Limit the catalytic activity and other problems, and achieve the effect of wide application range of pH, uniform and orderly pores, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) First, configure a mixed solution of 1mol / L copper nitrate, manganese nitrate and cerium nitrate (a mixed solution with copper nitrate, manganese nitrate and cerium nitrate concentration of 1mol / L each) for use;

[0029] (2) Next, repeatedly dip 1g of SBA-15 into 50mL of the above-mentioned mixed solution of copper nitrate, manganese nitrate and cerium nitrate (20g / L) and stir for 8h, then filter and dry;

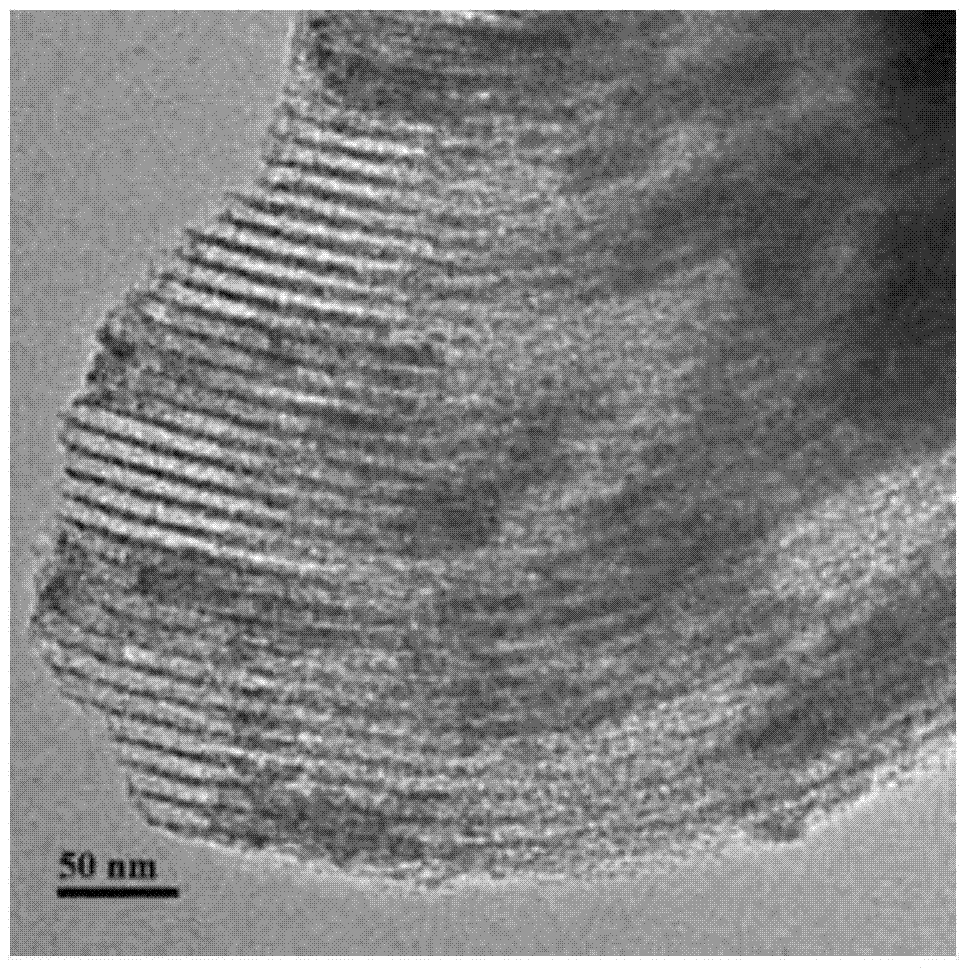

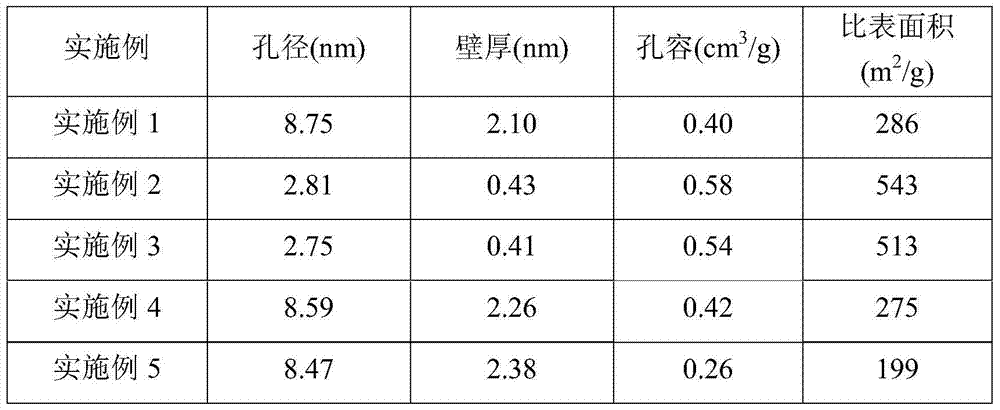

[0030] (3) Next, place the sample obtained in step (2) in a muffle furnace and calcinate at 300°C for 6 hours to obtain a heterogeneous Cu-Mn-Ce-based Fenton catalyst. The TEM picture is as follows figure 1 shown. Depend on figure 1 It can be seen that the catalyst shows a wide range of ordered strip structures along the [110] direction, and the shaded part in the figure is the active metal oxide successfully supported on the mesoporous silica. Its structural parameters are shown in Table 1;

[0031] (4) Then, add 0.2 g / L heterogeneous Cu-Mn-Ce Fenton catalyst...

Embodiment 2

[0034] (1) First, configure a mixed solution of 0.1mol / L copper nitrate, manganese nitrate and cerium nitrate for use (a mixed solution with a concentration of 0.1mol / L each of copper nitrate, manganese nitrate and cerium nitrate);

[0035] (2) Next, repeatedly dip 0.5g of MCM-41 into the above 50mL mixed solution of copper nitrate, manganese nitrate and cerium nitrate (10g / L) and stir for 4h, then filter and dry;

[0036] (3) Next, place the sample obtained in step (2) in a muffle furnace and calcinate at 500°C for 6 hours to obtain a heterogeneous Cu-Mn-Ce-based Fenton catalyst;

[0037] (4) Then, add 0.1 g / L heterogeneous Cu-Mn-Ce Fenton catalyst and 0.2 mol / L hydrogen peroxide to the 2000 mg / L high-concentration acid red 1 solution, adjust the pH to 3, and heat the solution to 70 ℃, let the system react for 210min, the results are shown in Table 2.

Embodiment 3

[0039] (1) First, configure a mixed solution of 0.5mol / L copper nitrate, manganese nitrate and cerium nitrate (a mixed solution with copper nitrate, manganese nitrate and cerium nitrate concentrations of 0.5mol / L each) for use;

[0040] (2) Next, repeatedly dip 2g of MCM-41 into 50mL of a mixed solution of copper nitrate, manganese nitrate and cerium nitrate (40g / L) and stir for 6h, then filter and dry;

[0041] (3) Next, place the sample obtained in step (2) in a muffle furnace and calcinate at 400°C for 6 hours to obtain a heterogeneous Cu-Mn-Ce-based Fenton catalyst;

[0042] (4) Then, add 0.4 g / L heterogeneous Cu-Mn-Ce Fenton catalyst and 0.8 mol / L hydrogen peroxide to the 1500 mg / L high-concentration rhodamine B solution, adjust the pH to 5, and heat the solution to 80 ℃, let the system react for 210min, the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com